04 arc starter service, Arc starter service -3, Pak 200i – Tweco PAK 200i User Manual

Page 57

PAK 200i

Manual 0-5335

MAINTENANCE

5-3

5.04 Arc Starter Service

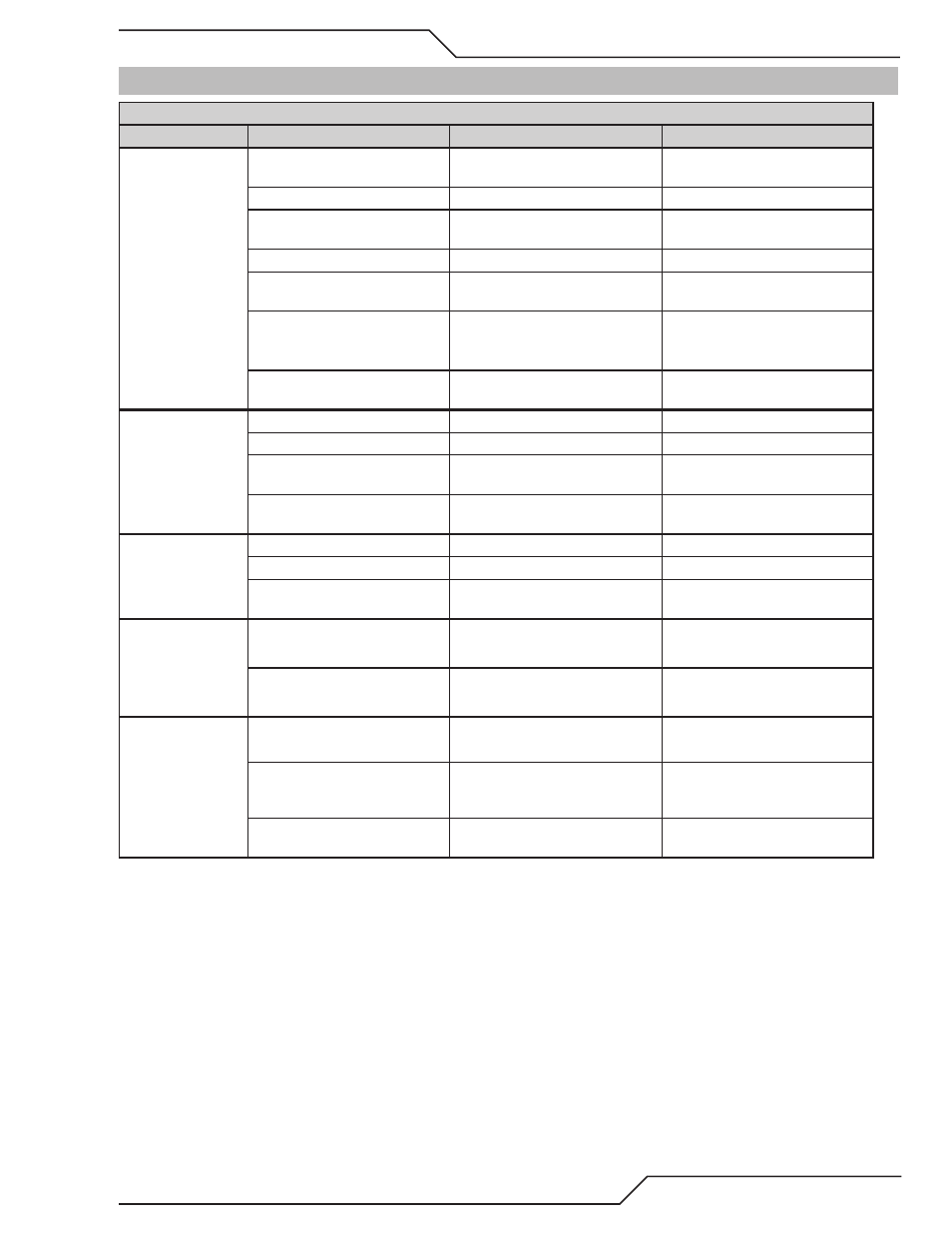

Arc Starter Service Chart

Symptom

Cause

Check

Remedy

No Pilot ignition:

Spark in Arc Starter

but no ignition

Coolant has become conductive

Use conductivity meter

Flush system,

replace coolant.

Spark gap set too close

Check with feeler gauge

Set to 0.063” ±0.002”

High Frequency cap (C4)

possibly open

Use capacitance meter

Reconnect or replace.

Broken or missing ferrites

Visual inspection

Replace.

Short across in inductor (L1)

Visual inspection

Remove short;

increase coil gaps.

Spark gap bus caps

(C1, C2, C3)

broken or defective

Capacitance meter

Replace.

Negative supply not

connected correctly

Visual inspection

Reconnect.

No Pilot ignition:

No Spark

in Arc Starter

Spark gap set too large

Check with feeler gauge

Set to 0.063” ±0.002”

Faulty transformer

Resistance measurement

Replace.

No 120V supply

Make connections;

replace harness.

No/ loose connection

to spark gap

Visual inspection

Reconnect.

No cooling or

insufficient cooling:

Leaks coolant

Loose fitting(s)

Visual inspection

Tighten fittings.

Failure to braze joints (L1)

Visual inspection

Replace HF Coil.

Damaged or punctured

coolant line(s).

Visual inspection

Replace coolant line(s).

No cooling or

insufficient cooling:

No Coolant Flow

Supply & return hose reversed Visual Inspection of color-coded

connections

Match coolant connection colors

to arc starter fitting colors.

Blockage in coil or

supply/return hoses

Loosen fitting slightly and check

for coolant flow

Flush system.

Erratic System

Behavior

(EMI Interference)

F1 ground not connected

Visual inspection of lead

attachment to Arc Starter

Reconnect / tighten

lead connectors.

Missing or loose

ground connection

Visual inspection of ground wire

to Arc Starter

Make or tighten

connections to

good ground.

Cap C5 not connected,

open or loose

Visual inspection / capacitor

measurement

Replace PCB.