Section 3: installation, 01 installation requirements, Section 3: installation -1 – Tweco PAK 200i User Manual

Page 25: Installation requirements -1, Pak 200i

PAK 200i

Manual 0-5335

INSTALLATION

3-1

SECTION 3: INSTALLATION

3.01 Installation Requirements

Electric Supply

The electrical supply network, the gas and water supply system must meet local safety standards. This

conformity must be checked by qualified personnel.

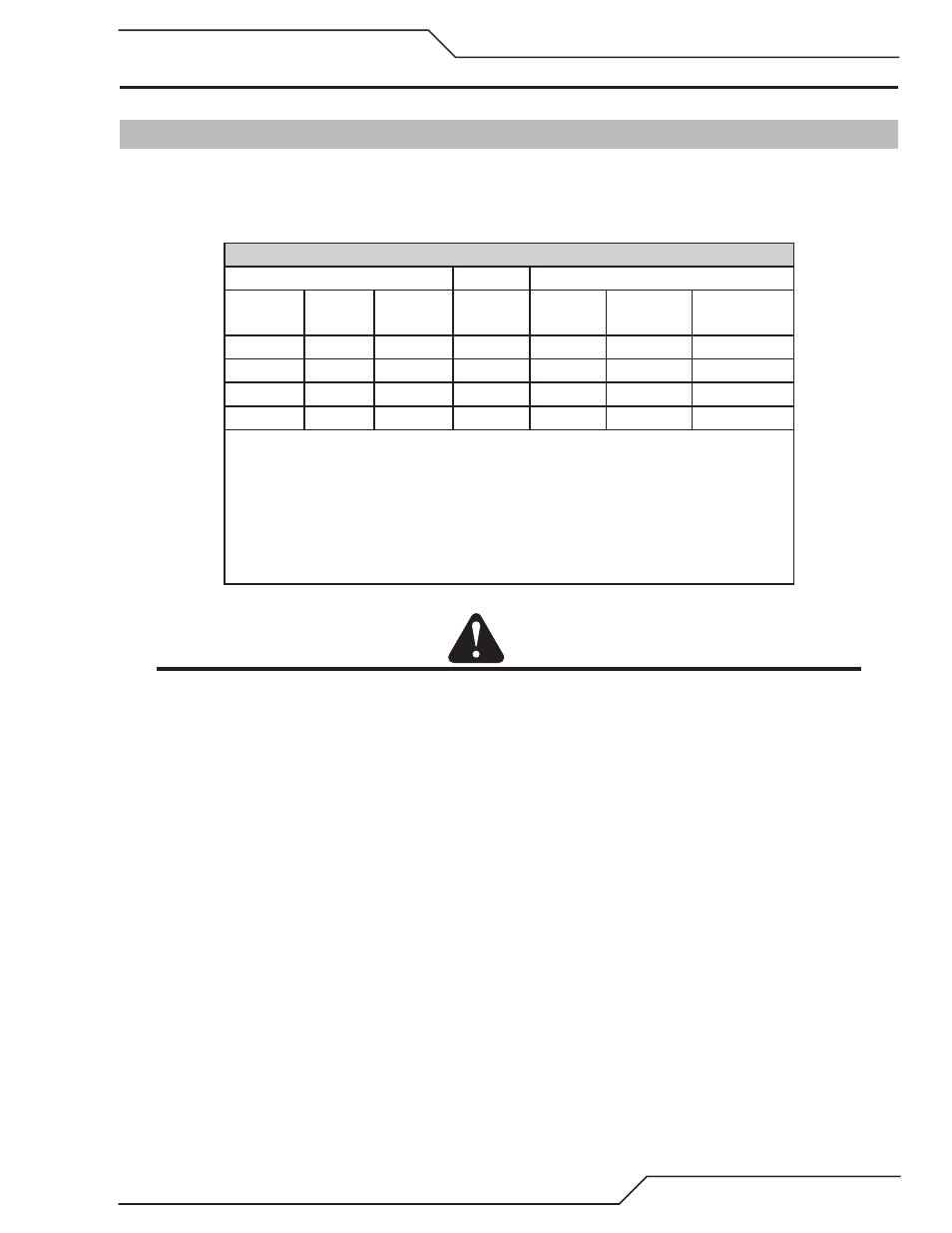

PAK 200i Power Supply

Input

Suggested Sizes (See Note)

Voltage

Freq.

Power

(3-Ph)

Current

(3-Ph)

Fuse

(Amps)

Wire (AWG)

Wire (mm

2

)

(Volts)

(Hz)

(kVA)

(Amps)

3-Ph

3-Ph

3-Ph

380

50/60

39

60

100

#6

16

400

50/60

39

57

100

#6

16

480

50/60

39

47

90-100

#8

10

* Suggested wire size based on United States NFPA 70 National Electrical

Code 2011 edition published by the National Fire Prevention Association. List-

ings are from table 400.5(A)(2) for flexible cord of certain types rated for 75

deg C in ambient temperatures up to 30 deg C. Using wires of lower tempera-

ture rating or different insulation type may require larger wire size. Derate for

higher ambient.

These are suggestions only. Always refer to your local and national codes that

apply to your region for final determination of correct wire type and size.

CAUTION

Fuse and wire sizes are for reference only. The installation must conform to national and local codes for the type

and method of wire being used.

Gas Supply

The customer must supply all gas and pressure regulators. Gases must be of high quality. Pressure regula-

tors must be double-stage and installed as close as possible to the gas console. Contaminated gas can cause

one or more of the following problems:

• Reduced cutting speed

• Poor cut quality

• Poor cutting precision

• Reduced consumables life.

• Oil or grease contamination from compressed or bottled air can cause fires in conjunction with oxygen.