Pak 200i, Mc3a mc3b m1 – Tweco PAK 200i User Manual

Page 152

PAK 200i

A-72

APPENDIX

Manual 0-5335

The fingers can be bent over or broken if reasonable care is not taken when the cartridge is not in place. If the

fingers are bent or broken it shortens the tube so the consumables may not push the tube in enough to open

the check valve resulting in no coolant flow. The coolant tube assembly may be replaced separately from the

torch head.

Some consumables use an extension on the coolant tube. A missing extension will not allow the check valve

to open.

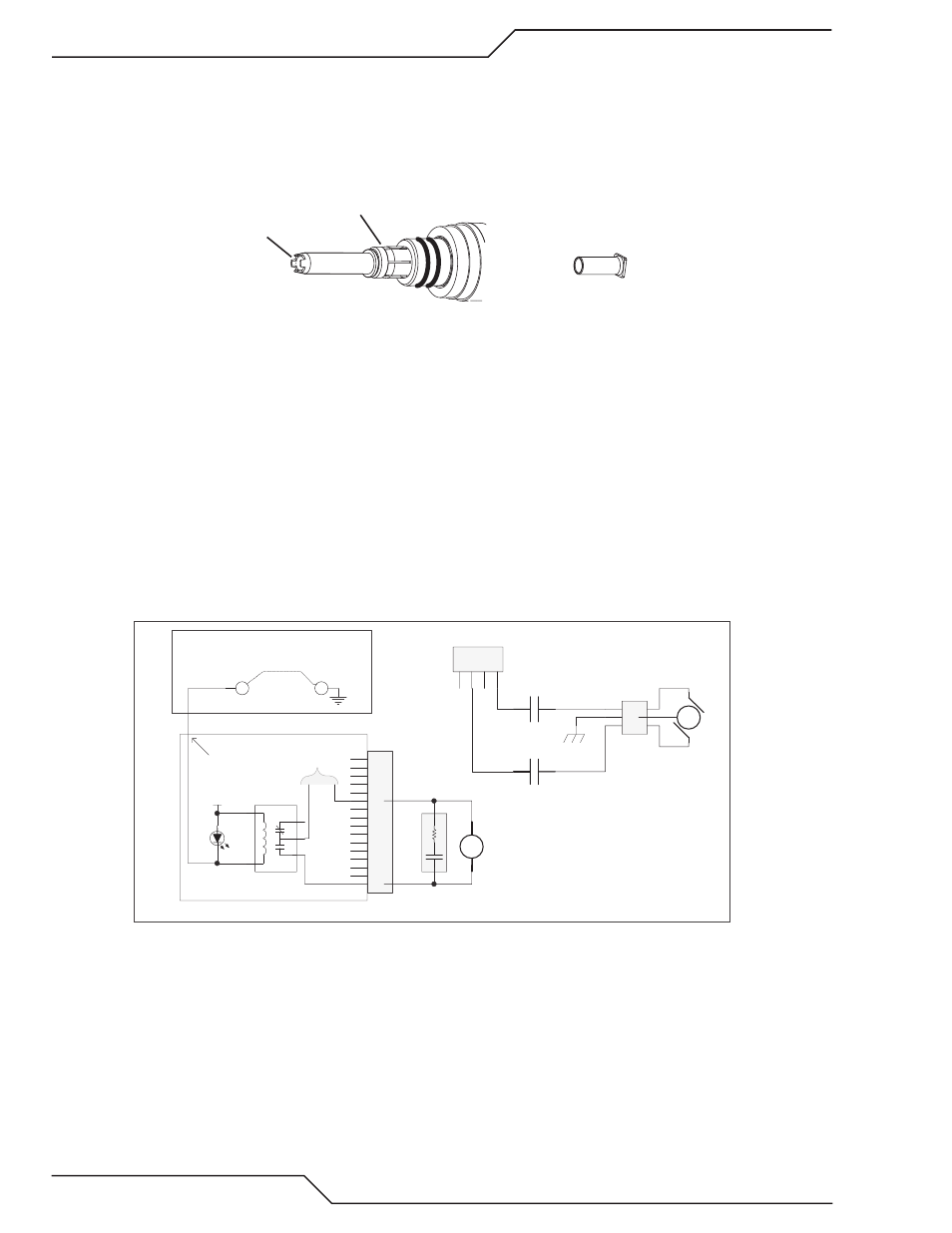

Art # 12312

Coolant Tube Extension

Fingers

Internal Check Valve

No Power to the Pump Motor

The pump motor is powered by 230 VAC controlled by the MC3 control relay. During the 4 minutes after turning

on power, before the 404 fault code is displayed, measure for 230 VAC at the motor connector J16 pin 1 to pin 3.

a. If the pump motor is not getting 230 VAC, measure for 24 VAC on the coil of MC3. If present and the relay

contacts aren’t closed the relay is defective. Note, the coil is rectified so you won’t measure continuity of

even a good coil.

b. If 24 VAC is not on the MC3 coil check for D27 on the relay board being ON. If it’s on the Relay board should

be providing the 24 VAC so if it’s not the Relay board may be defective. Measure for 24 VAC at J9-6 to J9-12

on the Relay board. If 24 VAC is present and D27 is on, the Relay board or the wire harness is defective.

c. If D27 is not on, measure on the CCM I/O board between TP3 and the common at TP1. It should be low,

near zero volts. If not the CCM is probably defective. Jumper TP3 (I/O board) to TP1. If the pump comes

on now replace the CCM.

d. If jumping TP3 to TP1 does not turn the fans on then the Relay board or the 40 pin ribbon cable pin 13 is at fault.

Art # 12313

MC3A

MC3B

M1

Torch Coolant Pump

1

2

3

J16

1

2

3

4

J13

(65B)

(66)

(67)

(64B)

CHASSIS GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J8

1

5

3

2

4

Coolant Pump Control

K5

MC3

Coolant pump Control

(163)

(162)

SA4

ARC_SUPPRESSOR

D27

24 VAC

Relay PCB

TP1

TP3

CCM I/O PCB

To test Pump relay jump TP3 to TP1.

+24

J4-13

230 VAC from T1

Coolant flows but flow is less than the required minimum:

Test and adjust the pump/bypass valve:

This test measures the “dead head” or blocked flow pressure at the rear panel coolant supply fitting. Perform

this test only after the coolant system is fully primed, that is after the coolant is circulated throughout the system

and is mostly free of bubbles. It requires a pressure gauge with #6 JIC fitting.

The gauge needs to be able to read at least 173 PSI. Remove the coolant supply hose and connect the pressure

gauge in its place. For the Auto-Cut 200 XT and PAK 200i connect the gauge in place of the torch coolant sup-

ply hose on the torch connection bulkhead. This is a #5 JIC fitting.