Pak 200i – Tweco PAK 200i User Manual

Page 122

PAK 200i

A-42

APPENDIX

Manual 0-5335

Art # 12300

Art # 12301

The

AC Suppression PCB has capacitors and other transient suppression components to protect the system from

transients on the AC lines. It also provides power for the neon AC present indicators which illuminate when AC

power is connected even with ON-OFF switch, CB1, off.

Differences between various models.

Auto-Cut 200 , 300 XT and Pak 200 XT units use the basic gas control/arc start circuits consisting of single gas inlets,

one for Plasma, one for Gas Shield and one for water inlet, optional for AC �00 XT, for H�O Mist shield (not offered

on Pak 200 XT). There is a pressure regulator and gauge for each gas inlet and water flow meter/control when the

H2O Mist option is used. All 3 are turned on/off with control solenoids. Changing gas types requires connecting

different gasses to the rear panel and setting the gas switch on the rear panel to match the plasma gas type. There

is no separate pilot (Preflow) gas at this time.

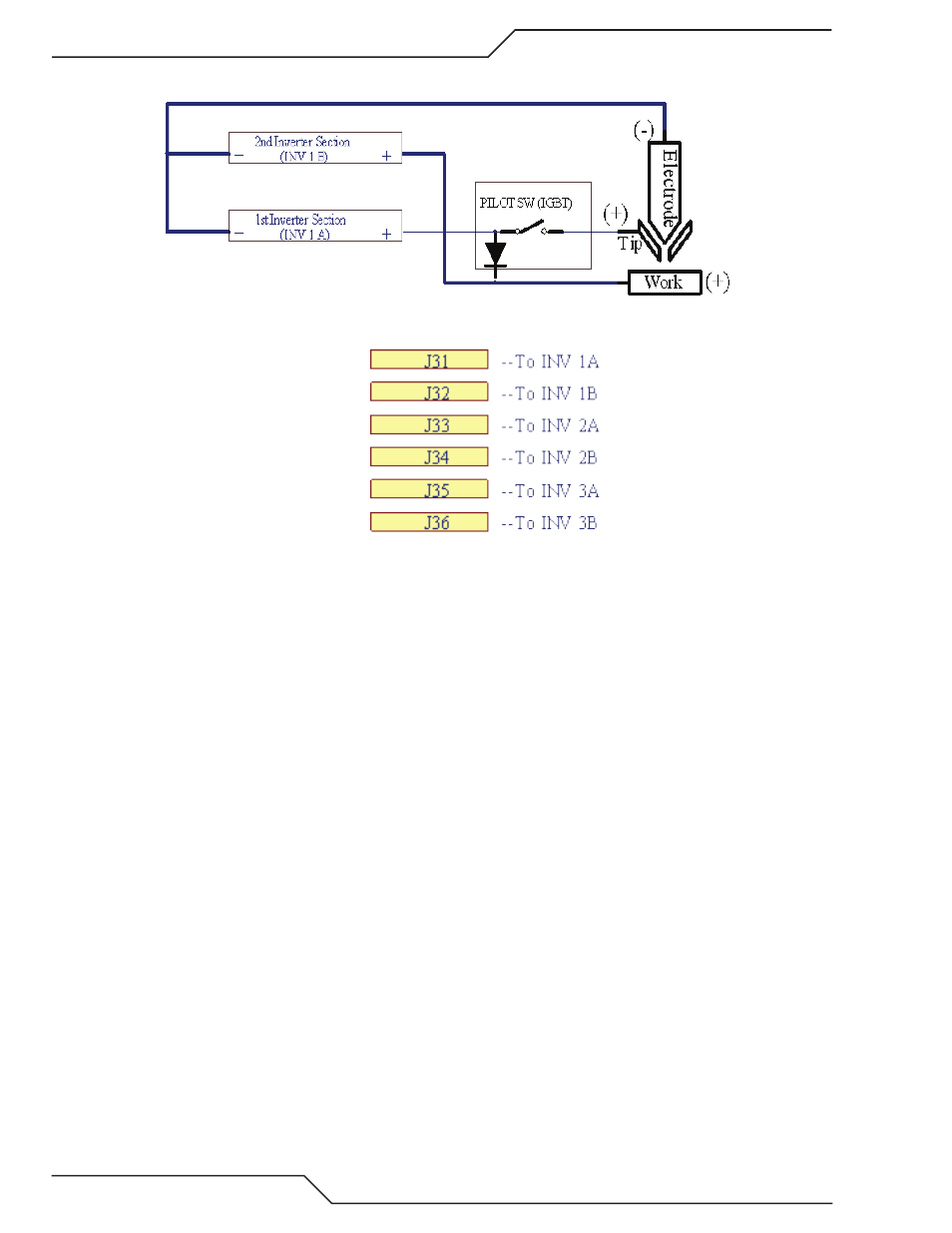

The Auto-Cut and Pak XT Arc starter is the conventional spark gap type with water cooled coil that we’ve used

for several years. This arc starter injects the HF onto the torch electrode via the negative lead with the return via

the tip and pilot lead. The Ultra-Cut XT units use the remote arc starter, RAS 1000 XT. In place of the spark gap the

RAS 1000 XT uses a solid state ignition module to create the HF pulses which are injected onto the tip and return

via the electrode, the opposite direction of that used in the Auto-Cut, Auto-Cut XT and the older RAS 1000 used

with the Ultra-Cut units.