08 recommended cutting speeds, Recommended cutting speeds -14, Pak 200i – Tweco PAK 200i User Manual

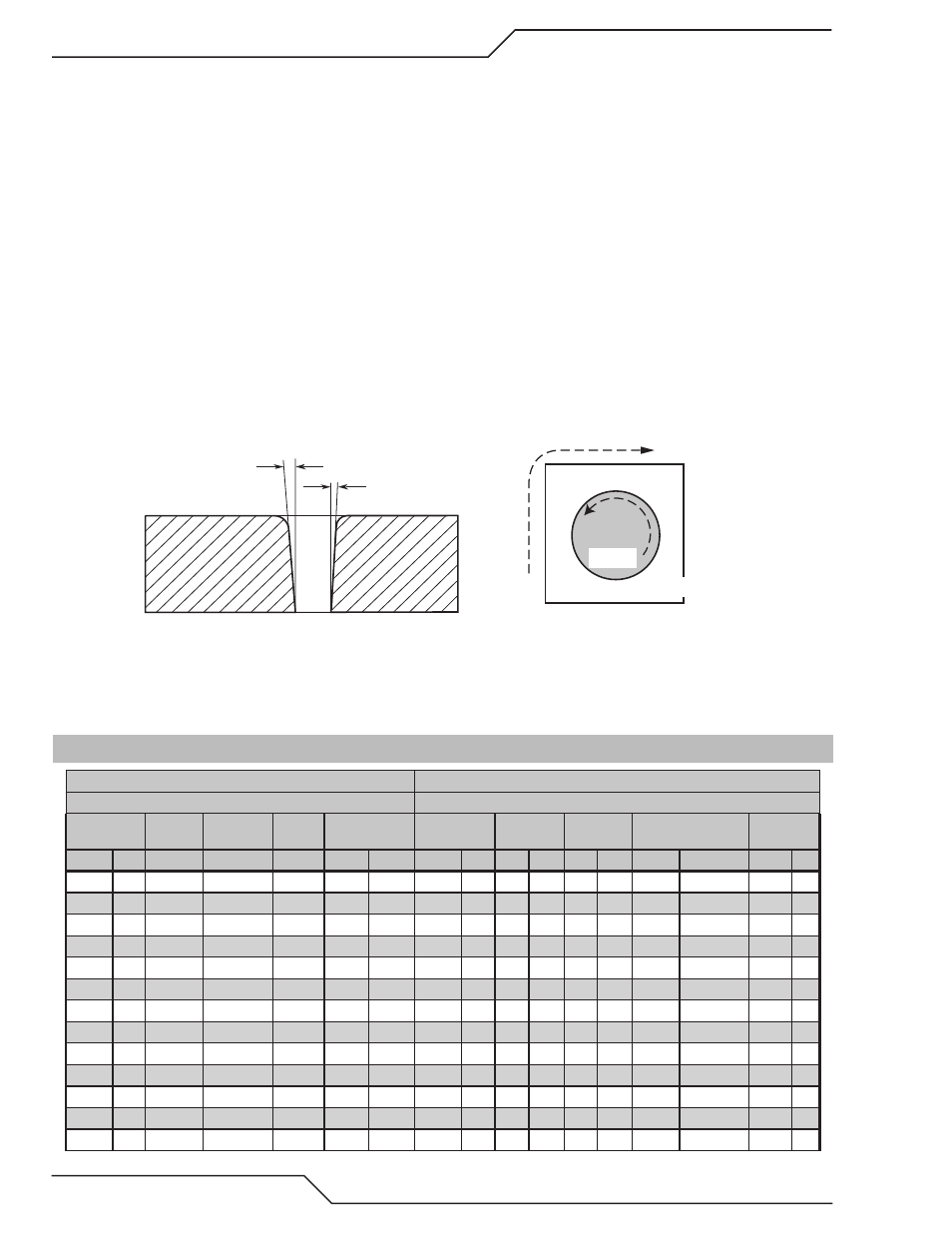

Page 52: Swirl effect on side characteristics of cut

PAK 200i

4-14

OPERATION

Manual 0-5335

Dross Build-up and Top Spatter

Dross is molten material which is not blown out of the cut area and re-solidifies on the plate. Top spatter is

dross which accumulates on the top surface of the workpiece. Excessive dross may require secondary clean-up

operations after cutting.

Kerf Width

The width of material removed during the cut.

Nitride Build-up

Nitride deposits which may remain on the cut edge of the carbon steel when nitrogen is present in the plasma

gas stream. Nitride buildups may create difficulties if the steel is welded after the cutting process.

Direction of Cut

The plasma gas stream swirls as it leaves the torch to maintain a smooth column of gas. This swirl effect results

in one side of a cut being more square than the other. Viewed along the direction of travel, the right side of the

cut is more square than the left.

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Scrap

Clockwise

Counter-

Clockwise

Art # A-04182

Workpiece

Scrap

Swirl Effect on Side Characteristics Of Cut

To make a square - edged cut along an inside diameter of a circle, the torch should move counterclockwise around

the circle. To keep the square edge along an outside diameter cut, the torch should travel in a clockwise direction.

4.08 Recommended Cutting Speeds

Type Torch: PCH-200

Type Material: Aluminum

Type Plasma Gas: Air

Type Secondary Gas: Air

Thickness

Tip

Output

Amperage

Speed

(Per Minute)

Standoff

Plasma Gas

Press

Sec Gas

Press

Total Flow (SCFH) Pierce Height

Inches mm (Cat. No.) Volts (VDC) (Amps) Inches Meters Inches mm

psi

bar psi bar Plasma Secondary Inches mm

0.032 0.8 32-1320

100

35

400

10.2

0.13

3.2

63

4.3

60

4.1

50

340

0.13 3.2

0.050 1.3 32-1320

100

35

250

6.4

0.13

3.2

63

4.3

60

4.1

50

340

0.13 3.2

0.063 1.6 32-1320

100

35

125

3.2

0.13

3.2

63

4.3

60

4.1

50

340

0.13 3.3

0.091 2.3 32-1320

110

35

90

2.3

0.13

3.2

63

4.3

60

4.1

50

340

0.13 3.3

0.125 3.2 32-1320

115

35

60

1.5

0.13

3.3

63

4.3

60

4.1

50

340

0.13 3.3

0.063 1.6 32-1321

118

70

200

5.1

0.13

3.3

50

3.4

60

4.1

60

332

0.13 3.3

0.125 3.2 32-1321

125

70

125

3.2

0.13

3.3

70

4.8

60

4.1

82

332

0.13 3.3

0.188 4.8 32-1321

125

70

85

2.2

0.13

3.3

70

4.8

60

4.1

82

332

0.13 3.3

0.25

6.4 32-1321

130

70

65

1.7

0.13

3.3

70

4.8

60

4.1

82

332

0.13 3.3

0.375 9.5 32-1321

140

70

25

0.6

0.13

3.3

70

4.8

60

4.1

82

332

0.25 6.4

0.500 12.7 32-1321

145

70

15

0.4

0.13

3.3

70

4.8

60

4.1

82

332

0.25 6.4

0.25

6.4 32-1322

125

120

125

3.2

0.19

4.7

60

4.1

60

4.1

78

340

0.25 6.4

0.375 9.5 32-1322

130

120

70

1.8

0.19

4.8

60

4.1

60

4.1

78

340

0.25 6.4