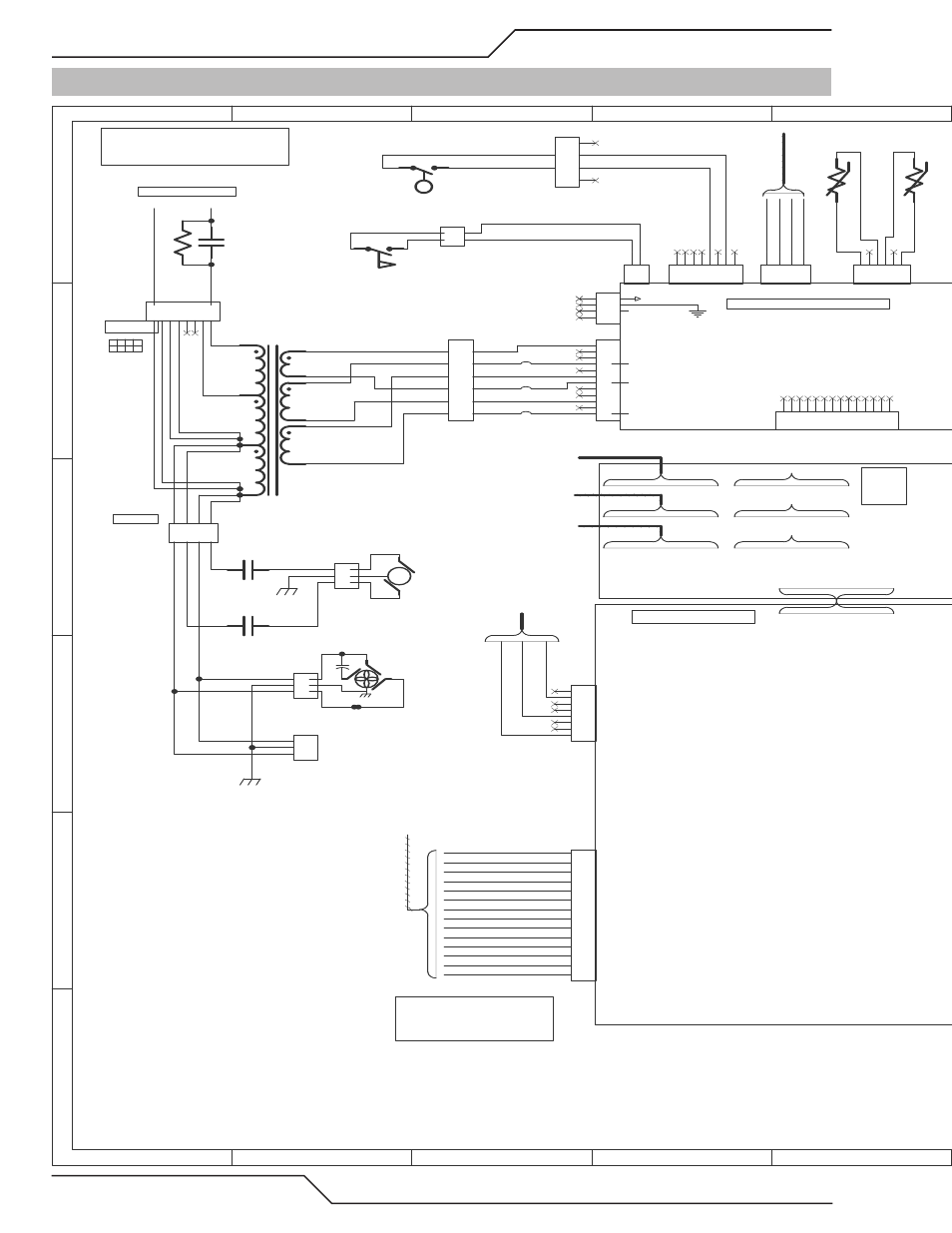

System schematic 480v - pg2, Pak 200i, Tip vol ts work arc vol ts – Tweco PAK 200i User Manual

Page 118: Ccm cpu pcb ccm i-o pcb, Mc3a mc3b, Mc1a r2, Fan1

PAK 200i

A-38

APPENDIX

Manual 0-5335

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

F

F

E

E

D

D

C

C

B

B

A

A

Rev

Revision

By

Date

Rev

Revision

By

Date

042X1364

C

2

2

02/14/2014

DAT

Victor Technologies Headquarters

16052 Swingley Ridge Road, Suite 300

St Louis, Missouri 63017 USA

Drawn

Date

Sheet

of

Size

Drawing Number

SCHEMATIC

PAK 200i 480VAC

The information contained herein is proprietary to Victor Technologies.

Title

Not for release, reproduction or distribution without written consent.

7/8/2014

Date Printed

Date Revised

7/2/2014

Rev

Revision

By

Date

Rev

Revision

By

Date

00

INITIAL

DAT

2/14/2014

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

J10

HMI/GCM

1

2

3

4

5

6

7

8

9

10

11

12

J9

BIAS TRANSFORMER

120 VAC to RAS

120 VAC Ret

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

J22

RELAY & INTERFACE PCB

CCM

CPU

PCB

CCM I-O PCB

J4 -- 40 CKT RIBBON CABLE

1

2

3

4

J6

TORCH FLOW SENSOR

1

2

3

4

5

6

J2

TEMP SENSOR

1

2

3

4

5

6

7

8

J7

LEVEL SENSORS

1

2

J5

COOLANT FLOW SW

1

2

3

4

5

6

7

8

J24

J29 30 CKT PIN HEADER

J29 30 CKT RECEPTACLE - BOTTOM ENTRY

J17

16 CKT RIBBON

Display PCB

460V

400V

220V

0 V

Mini-Fit Jr

24V

24V RET

120V_2

TS1

COOLANT

TS2

AMBIENT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

J8

CONTROL OUTPUTS

J28 30 CKT PIN HEADER

J28 30 CKT RECEPTACLE - BOTTOM ENTRY

1

2

3

4

5

6

J30

W1

TO PILOT PCB J42

TO HC

T1 (

Wor

k)

+15 VDC

-15 VDC

COMMON

SIG (+)

FS1

COOLANT

CB2

5 A

CB3

5 A

CB4

5 A

120V-1 RET

120V_2 RET

Mini-Fit Jr

From J63 (Sht 1, F2)

Harness from System Bias PCB

120 VAC_1

24 VAC

24 VDC

PIL

OT A SIG

Vin+

PIL

OT A SIG

Vin-

PIL

OT ENABLE

PIL

OT ENABLE RE

T

10 CKT RIBBON

J37

1 2 3 4 5 6 7 8 9

J38

RS 232 D-SUB

SERIAL PROG

PORT

1 2 3 4

J39

USB

PORT

1

2

3

4

5

6

7

8

9

10

11

12

J20

2 WIRE

4 WIRE

1

2

3

4

5

6

7

8

9

10

11

12

J19

NORM

AL

PR

OGR

AM

J31 - 30 CKT RIBBON

J32 - 30 CKT RIBBON

J33- 30 CKT RIBBON

To J100 of IM #2A

TIP VOL

TS

WORK

ARC VOL

TS

Harness from Pilot PCB J45

0.25 GPM

1

2

3

4

J1

WORK CURRENT SENSOR

1

2

3

4

5

6

7

8

9

10

J3

PILOT PCB

GND

To J100 of IM #1A

To J100 of IM #1B

1

2

3

4

5

6

J18

PROG

USB IC

GAS ON

ENABLE

PLAS_ENABLE SW

PLAS_ EN_SW_RET

/ GAS PRESS OK

GND

/ BASIC ID

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

J21

GND

+10V

GND

1

2

3

4

5

6

J14

120V_1

BLUE

BLUE

RED

RED

YELLOW

YELLOW

J12 = Mini-Fit Jr

400 VAC -- Single 18 AWG in pins 1 & 4

480 VAC -- Single 18 AWG in pins 1 & 8

230 VAC -- 18 AWG wires in pins 1,5,2,6

1

2

3

4

5

6

7

8

J12

1

2

3

4

5

6

7

8

1

2

3

4

J13

19X501200

019X501700

019X501100

(29)

(30)

(31)

(32)

(33)

(34)

(35)

(36)

(37)

(38)

(39)

(40)

(41)

(42)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J27

24 VDC

24 VDC

24 VDC_RET

24 VDC_RET

MISSING PHASE a

MISSING PHASE b

AC V HIGH a

AC V LOW a

AC V LOW b

AC V HIGH b

VAC_IDA a

/ VAC_IDA b

VAC_IDB a

/ VAC_IDB b

(43A)

T1

(57)

(58)

(59)

(56)

/ CNC Plasma Enable (+)

/ CNC Plasma Enable (-)

(71)

(72)

(73)

(74)

(75)

(76)

(77)

(78)

(79)

(53)

(51)

(55)

(83)

(84)

(89)

(90)

(93)

(92)

(94)

(95)

(96)

1

2

J74

(97)

(98)

(99)

Tx+

GND

GND

Tx-

Rx+

Rx-

(121)

(123)

(124)

(125)

(126)

(127)

(129)

(130)

(133)

(137)

(131)

(133)

(104)

(136)

(134)

(135)

(139)

(138)

(134)

(135)

(136)

(137)

(138)

(139)

(140)

(141)

(140)

(141)

PSR

SPARE #1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J15

1 TORCH INTERFACE

. 230V 400V 480V ERR

J62-12 (/VAC_IDAb) 0 1 0 1

J62-14 (/VAC_IDBb) 0 0 1 1

Measured relative to TP1 (24VDC_RET)

"0" = 10-12V "1" = 24V

1

2

3

4

J71

SOL1

PLASMA

SW 1

RUN / SET

PS1

PLASMA (51 PSI)

SOL2

SHIELD

AC 24V Ret-GCM2 (D9)

AC 24V Ret-GCM2 (B8)

(111)

(111)

AC 24V-GCM2 (B8)

AC 24V-GCM2 (D9)

(104)

(130)

(131)

(123)

(124)

R1

10K

(130)

(127)

(125)

(126)

(128)

SA1

ARC_SUPPRESSOR

AC 120V (Sht 1, A7)

AC 120V_RET (Sht 1, A7)

AC 24V- Ret -TB4-1 (Sht 1, D8)

AC 24V-TB4-2 (Sht 1, D8)

AC 120V- Ret- TB4-3 (Sht 1, C8)

AC 120V- TB4-4 (Sht 1, C8)

(62)

(60)

(63)

(61)

(Sht 1, C6)

(Sht 1, B6)

(Sht 1, B6)

(Sht 1, A6)

(Sht 1, E4)

(Sh

t 1, D7)

(Sht 1, C7)

120 VAC_RET

CURRENT

CONTROL

D2, GREEN, 1TORCH GAS ON

D7, GREEN, PILOT ENABLED

D11, GREEN, PILOT CURRENT

D12, GREEN, WORK CURRENT

D22, GREEN, CONTACTORS ON

D23, GREEN, RF ON

D24, GREEN, FANS ON

D25, GREEN, PLASMA ENABLED

D26, GREEN, 1TORCH ON

D27, GREEN, COOLANT ON

1

2

3

4

5

6

7

8

9

10

11

12

TB1

+10V (CC Pot Hi)

CC Pot Wiper

CC Pot Low

Div Arc V (+)

Div Arc V (-)

Start - Stop (+)

Start - Stop (-)

Stop Mom NC

CNC Enable (+)

CNC Enable (-)

1

2

3

4

5

6

7

8

9

10

11

12

TB2

PILOT is ON

PILOT is ON

Preflow ON (+)

Preflow ON (-)

Hold Start (-)

Hold Start (+)

1

2

3

4

5

6

7

8

9

10

11

12

TB3

Spare #2 NO

Spare #2 NC

Spare #1b NO

MC3

Pump Motor Control

(163)

(162)

SA2

ARC_SUPPRESSOR

Input Contactor

I / O PCB LEDS

----------------------------------------------

D2 CNC PLASMA ENABLE

D3 E-STOP_PS

D4 GAS ON (Auto-cut, PAK)

D6 CNC START

D8 HOLD START

D12 PREFLOW ON

D13 CSD (corner current reduction)

D18 MARK

D20 SPARE

D25 EXP METAL

D33 OK_CNC

D37 PSR

D41 SPARE OUT 2

D43 SPARE OUT 1

I / O PCB TEST POINTS

-------------------------------------

TP1 PCB COMMON

TP2 COOLANT FANS ON

TP3 PUMP ON

TP4 LOW FLOW (SW)

TP5 FLOW SIGNAL (pulse, Ultracut only)

TP6 +15VDC_ISO (ref to TP10)

TP7 -15VDC_ISO (ref to TP10)

TP8 +16-18 VDC_ISO (ref to TP10)

TP9 ANALOG CURRENT SIGNAL

(remote & Autocut only)

TP10 ISOLATED VOLTAGE COMMON

TP11 1 TORCH CONTACTOR ON

TP12 +5 VDC

TP13 -15 VDC

TP14 +15 VDC

TP15 +24 VDC

TP18 +5 VDC_ISO (ref to TP10)

CPU PCB LEDs

----------------------------

D2 RXD (red)

D3 TXD (red)

D4 CAN BUS (slave)

D7 CAN BUS (MAIN)

D11 5 VDC POWER

D17 STATUS CODE

D18 INITIALIZING /

PROGRAMMING (red)

CPU PCB TEST POINTS

--------------------------------------------

TP1 GND (PCB common)

TP2 +5V_ISO (REF TP5)

TP3 +24 VDC

TP4 +3.3V

TP5 GND_ISO

TP6 +5.0 V

TP7 TOTAL DEMAND

(3.3V = 400A)

TP9 /WR

TP10 /RD

TP11 CPU TEMP SENSE

TP12 +3.3VA

TP13 -15VDAC

TP14 PC2

TP15 +15VDAC

TP16 CLKO

TP18 OSC_CLOCK

I / O PCB DIP SW

---------------------------------------------

SW6 OK TO MOVE

(CONTACTS, VOLTS)

SW11 ANALOG CC SOURCE

SW12 DIVIDED ARC VOLTAGE

(50:1, 16.7:1, 30:1, 40:1, 25:1)

CPU PCB DIP SW

---------------------------------------------

SW1 AUTO PILOT RESTART

SW3 PREFLOW TIME

SW4 POSTFLOW TIME

SW5 FUNCTION

SW8 SYSTEM CONTROL

(pilot time, etc.)

SW9 RESERVED (future)

SW10 ADDRESS (default = 0)

SW13 UNIT TYPE (AC / UC)

SW14 LINE TERMINATION

(serial comm.)

J23- 40 ckt ribbon cable

LS1

COOLANT LEVEL

019X501800

+5VDC

SIGNAL

J34 - 30 CKT RIBBON

J34 - 30 CKT RIBBON

J34 - 30 CKT RIBBON

N/C

N/C

N/C

4- / CNC Start (-)

3- / CNC Start (+)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J15-CNC

1

2

3

J16

230 V

AC

M1

Torch Coolant Pump

(64)

(64B)

(65)

(64C)

MC3A

MC3B

(65B)

(66)

(67)

(64B)

1

2

3

J73

(65A)

(64A)

(65C)

OK

RUN

SET

(44A)

MC1A

R2

4.7 30W

(87)

1

5

3

2

4

INRUSH

K1

MC1

120VAC

(60)

(61)

(63)

(62)

(107)

CHASSIS GND

CHASSIS GND

CHASSIS GND

120 VAC_2

120VAC_1

120VAC_2

24VAC

Test Points

TP1, GND

TP2, -15V

TP3, +5VDC

TP4, +12V

TP5, +24V

TP6, +15V

TP7, +5VDC

1

2

3

J72

C4

FAN1

R

R

BK

BN

BL

Ferrite core

3 turns

01

DAT

7/2/2014

Fan, Flow SW, text changes

Art # A-12402

System Schematic 480V - pg2