Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 9

2:4

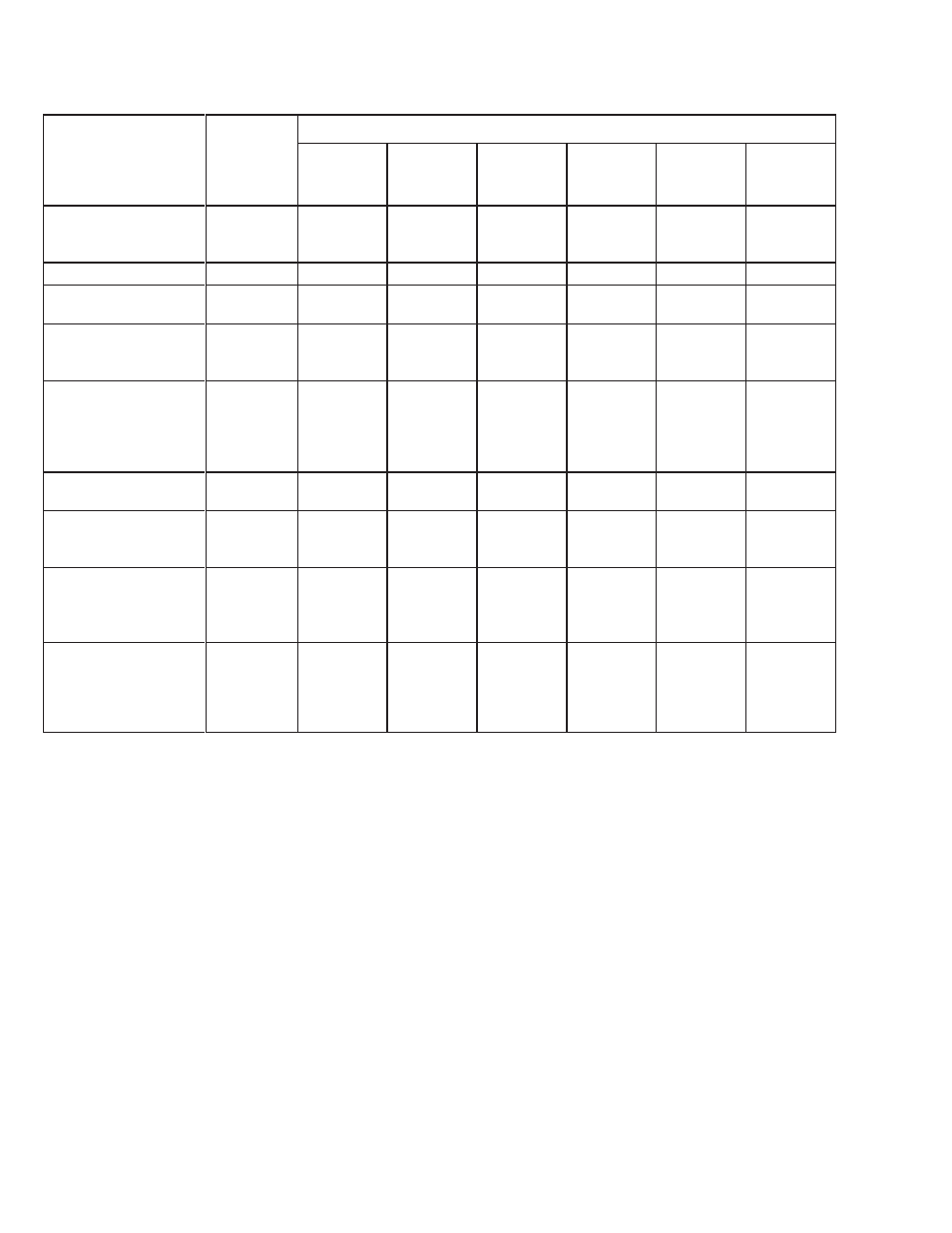

Table 2Ć1A. LocalOperator ControlFaceplates

Specify

Operator's

Functions Provided

1

When Using A

MinPak Plus

Controller With:

Operator's

Control

Faceplate

Model

Start/

Stop

SpeedĆ

setting

Pot

TorqueĆ

setting

Pot

Run/

Jog

Selector

Forward/

Reverse

Selector

AutomatĆ

ic/Manual

Selector

Blank Faceplate

(Use with Remote

Station)

14C200

no

no

no

no

no

no

Basic Features

14C201

yes

yes

no

yes

no

no

Basic Features Plus

ArmatureĆReversing

14C202

yes

yes

no

yes

yes

no

Basic Features Plus

Automatic/Manual

Modes of Operation

14C203

yes

yes

no

yes

no

yes

Basic Features Plus

ArmatureĆReversing

and Automatic/

Manual Modes of

Operation

14C204

yes

yes

no

yes

yes

yes

Basic Features Plus

Torque Control

14C205

yes

yes

yes

yes

no

no

Basic Features Plus

ArmatureĆReversing

and Torque Control

14C206

yes

yes

yes

yes

yes

no

Basic Features Plus

Torque Control and

Automatic/Manual

Modes of Operation

14C207

yes

yes

yes

yes

no

yes

Basic Features Plus

ArmatureĆReversing,

Torque Control and

Automatic/Manual

Modes of Operation

14C208

yes

yes

yes

yes

yes

yes

Remote Station

If the application requires the

Operator Control Station to be

remotely located, the following three

steps must be followed:

D Select the blank Remote

Operator Station Cover

Faceplate (Model 14C200)

D Order aRemote Operator

Adapter Kit, Model 14C200. (This

unit provides aconnection point

for the Remote Station.)

D Specify aReliance Remote

Operator Control Station and

then connect it to the Controller.

Refer to Table 2Ć1B.

NOTE: Whenever a reference kit and

remote operator buffer kit are used

without an auto/manual switch, do

the following:

1. Cut the J1 jumper on all

reference kitsused, and

2. Add a jumper from terminal

326 to 426 on the remote

operator buffer kit.