Startćup and adjustment, General, Figure 4ć1. regulator module screen – Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 24

4:1

4: StartĆup and Adjustment

General

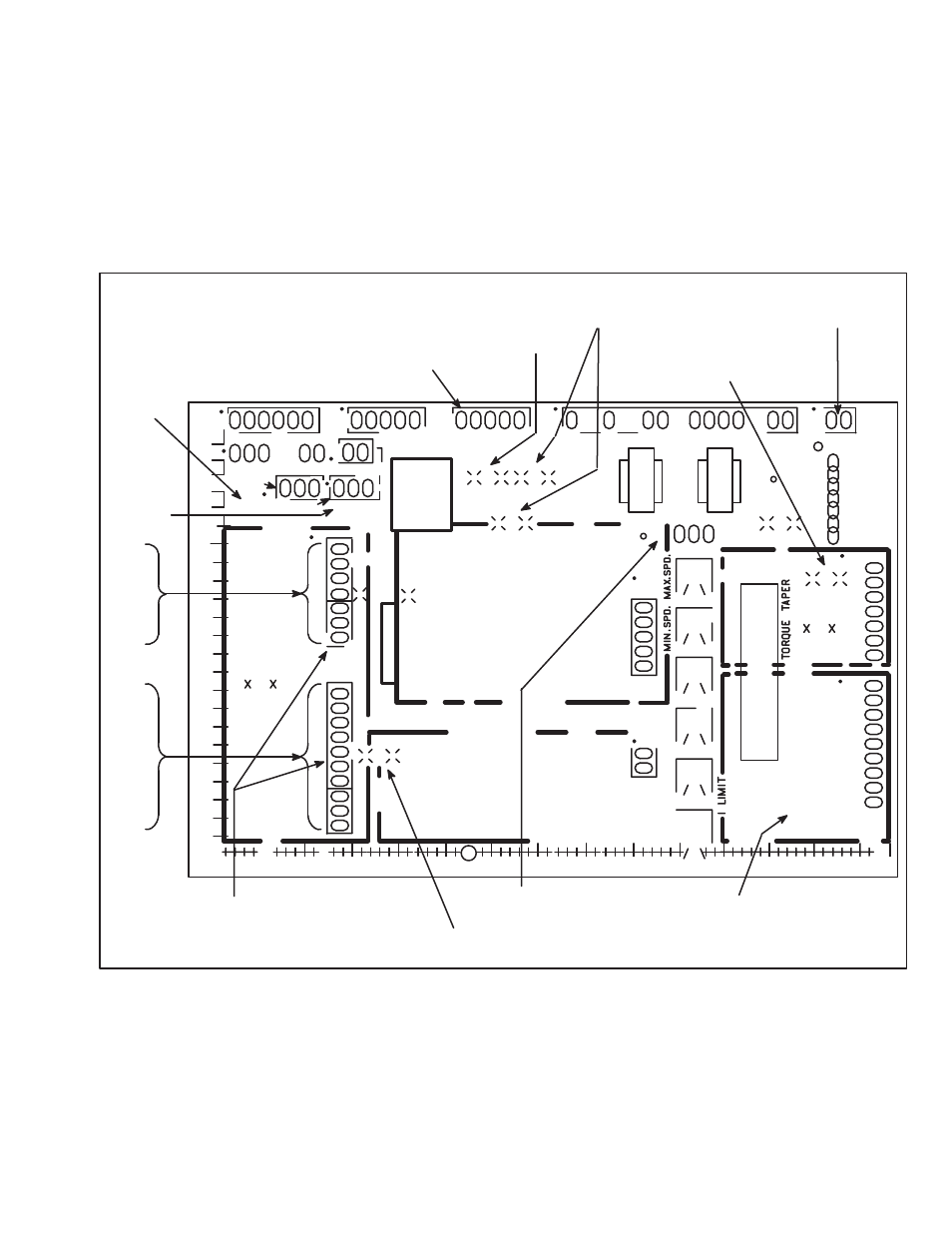

This section details the startĆup and

adjustment for the basic MinPak

Plus Drive as an armature voltage

regulator and/or as a speed

regulator. Reference Figure 4Ć1 for

location of adjustments, test points

and the relative positioning of

optional kits on the regulator

module. Record final settings of

potentiometers and jumpers in

Table 4Ć3.

J

BRN

382

B

C

D

E

F

G

K

L M

N

P

Q

R

S

T

U

V

W X

Y

Z

AA

AB

AC

AD

AE

AF

AG

AH

AJ

AK

AL

AM

AN

AP

AQ

AR

AS

AT

AU

AV

AW

AX

AY

AZ

BA

61 62 60

XFORMER

ORG

139

RED THM

32

AUX.M.

YEL 39

40 AUTO

REV

PUR

Auxiliary M

connects

here

Place 3Ćwire

connector

from Auto

Reversing

Module

here.

28

GRN

56

57

99

71

20

26

Local Operator's

Control connects here

67

326

126

26

65

66

39

32

35

38

OPERATOR

INTERCON.

RED 32

J4

J3

J6

J9

J5

REFERENCE

TACH. FDBK.

J8

COM

DEC.

TEST

0

0

0

0

ACC.

IR

COMP.

C T A

57

326

56

71

57

26

719

56

17

16

271

256

126

57

71

419

85

87

86

319

219

56

57

Feedback

Jumpers

Test at Test

Meter Adapter

pins only.

2.5

3.7

5

7.5

10

15

25

AMPS

I

FDBK.

RED

YEL

BLU

66 REV.

45

ARM.

FDBK.

47 FDBK.G2 L2

G3 47 G4 47

L1 G1

192193

CLIP FOR

50HZ

COM

Place 5Ćwire connector from

Reversing Contactor here.

Remove J9 if using

Reversing Contactor

Route standard twisted

pair I FDBK. to right of

the RM Contactor.

Remove J7 and J8 if

using Torque Taper Kit.

J7

0

5

10

15

20

25

30

35

40

45

55

60

65

70

0

0

FWD.

Remove J5 and J6

for 230VAC Drive opĆ

eration

CLIP FOR

50HZ

Remove J4 if Auto/Manual Selector is installed

382 282

281 482 481 57

139 36

65 39 38

66 67

38 139 36

Figure 4Ć1. Regulator Module Screen.