Power off inspection, Motor ground check, 50 hertz operation – Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 25: 230 volt aćc applications, Horsepower - current scaling

4:2

DANGER

ONLY QUALIFIED ELECTRIĆ

CAL PERSONNEL FAMILIAR

WITH THE CONSTRUCTION

AND OPERATION OF THIS

EQUIPMENTAND THE HAZĆ

ARDS INVOLVED SHOULD

INSTALL, ADJUST AND/OR

SERVICE THIS EQUIPMENT.

READ AND UNDERSTAND

THIS MANUAL IN ITS ENTIREĆ

TY BEFORE PROCEEDING.

FAILURE TO OBSERVE THIS

PRECAUTION COULD REĆ

SULTIN SEVERE BODILY

INJURY OR LOSS OF LIFE.

DANGER

THIS EQUIPMENT IS AT LINE

VOLTAGE WHEN AĆC POWER

IS CONNECTED. DISCONĆ

NECTAND LOCKOUTALL

UNGROUNDED

CONDUCĆ

TORS OF THE AĆC POWER

LINE. FAILURE TO OBSERVE

THESE

PRECAUTIONS

COULD RESULTIN SEVERE

BODILY INJURY OR LOSS OF

LIFE.

Power Off Inspection

NOTE: These procedures assume

that the AĆC incoming line is locked

off and that the load is uncoupled

from the motor.

Inspect the Controller and

modification kits for possible

physical damage or improper

connections. Electrical connections

between the modification kits and

the Regulator are made via box

connectors over board pins. Before

inserting the kits, verify that the

mating pins are straight and

parallel. Only one pin will fit in each

box connector. All kits are to be

securely fastened to the regulator

board by the screws provided.

Verify the wiring of the operator's

station and wiring to the Drive. All

wire connections should be made

with sufficient bare wire to make a

good electrical connection. The

removal of an excessive length of

insulation may needlessly expose

conductors with the possibility of

shorts or safety hazards resulting.

Motor Ground Check

The DĆC Motor frame and conduit

box should be connected to a good

earth ground per the motor

instruction manual.

Verify that there is no path to

ground in either the DĆC Motor

armature circuit, the shunt field

circuit or the thermostat circuit.

Connect one lead of an ohmmeter

to the motor frame and the other

lead to the two armature leads, the

two field leads and to the two

thermostat leads. If a reading of less

than 100,000 ohms is observed, a

ground condition exists and MUST

be cleared before power is applied.

CAUTION: A meggar may be

used for this motor ground

check, but all conductors beĆ

tween the motor and the controlĆ

ler must be disconnected. FailĆ

ure to observe this precaution

could result in damage to, or deĆ

struction of, the equipment.

50 Hertz Operation

When the Drive is used in 50 hertz

applications, it is necessary to clip

two resistors on the Regulator

Board. These resistors are located

at grid AF4 to AF10 and AA63 to

AA69.

230 Volt AĆC

Applications

For 230 VAC applications, the

FlexPak Plus Regulator must be

modified by clipping jumpers J6

and J5. See Figure 4Ć1. This

modification has probably been

made at the factory upon Model

Number specification, however, this

should be verified. Clip both sides

of the jumpers to ensure a clean

circuit break.

Horsepower - Current

Scaling

Since a MinPak Plus Drive covers a

wide range of horsepower ratings

(see Table 4Ć1), it is necessary to

scale the Drive for the application

motor. The Current Scaling Jumper

on the Regulator Board must be set

for the specific motor full load

current rating. Locate the nameplate

on the drive motor and then note

the fullĆload current. If current is not

shown on the nameplate, refer to

Table 4Ć1. Relate the left or center

columns in Table 4Ć1 with known

motor data. Read across to the right

column marked "Motor Current".

This value indicates the proper

jumper connection to make on the

Regulator Board where a

corresponding number is etched on

the Printed Circuit Board.

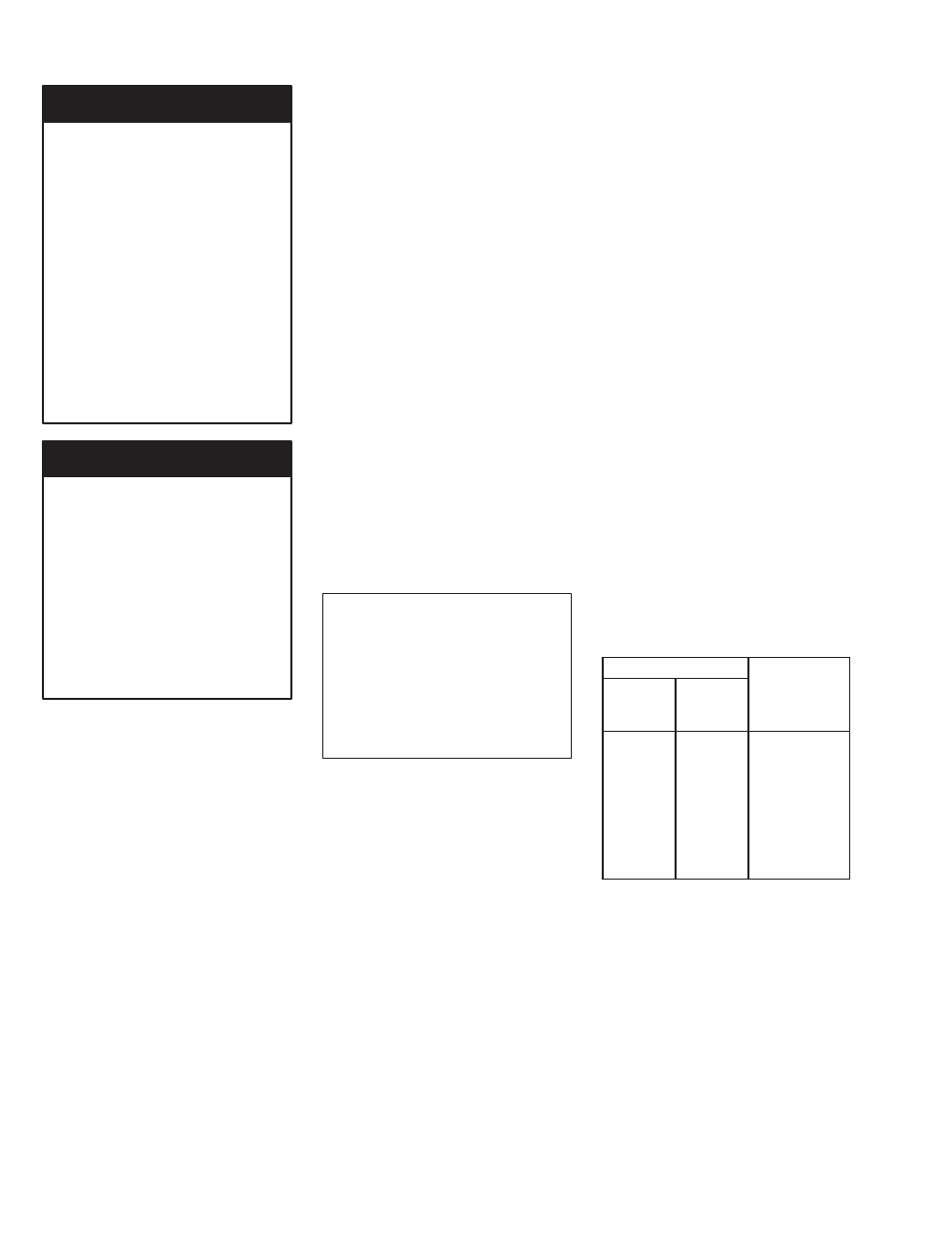

Table 4Ć1. Current Feedback

Scaling

Motor HP

115 VAC 230 VAC

Motor

Current/PIN

Connections

1/4

1/2

2.5A

1/3

3/4

3.7A

1/2

1

5.0A

3/4

1 1/2

7.5A

-

2

10.0A

-

3

15.0A

-

5

25.0A

Refer to Figure 4Ć2 to select the

appropriate current scaling

connection. Place the current

scaling jumper on the proper

connection. NOTE: Do not move the

jumper if it is connected to the

proper connection.

If the jumper must be reconnected,

carefully lift it straight up and off the

connector. Slide the jumper straight

down over the proper connection.