Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 49

A:2

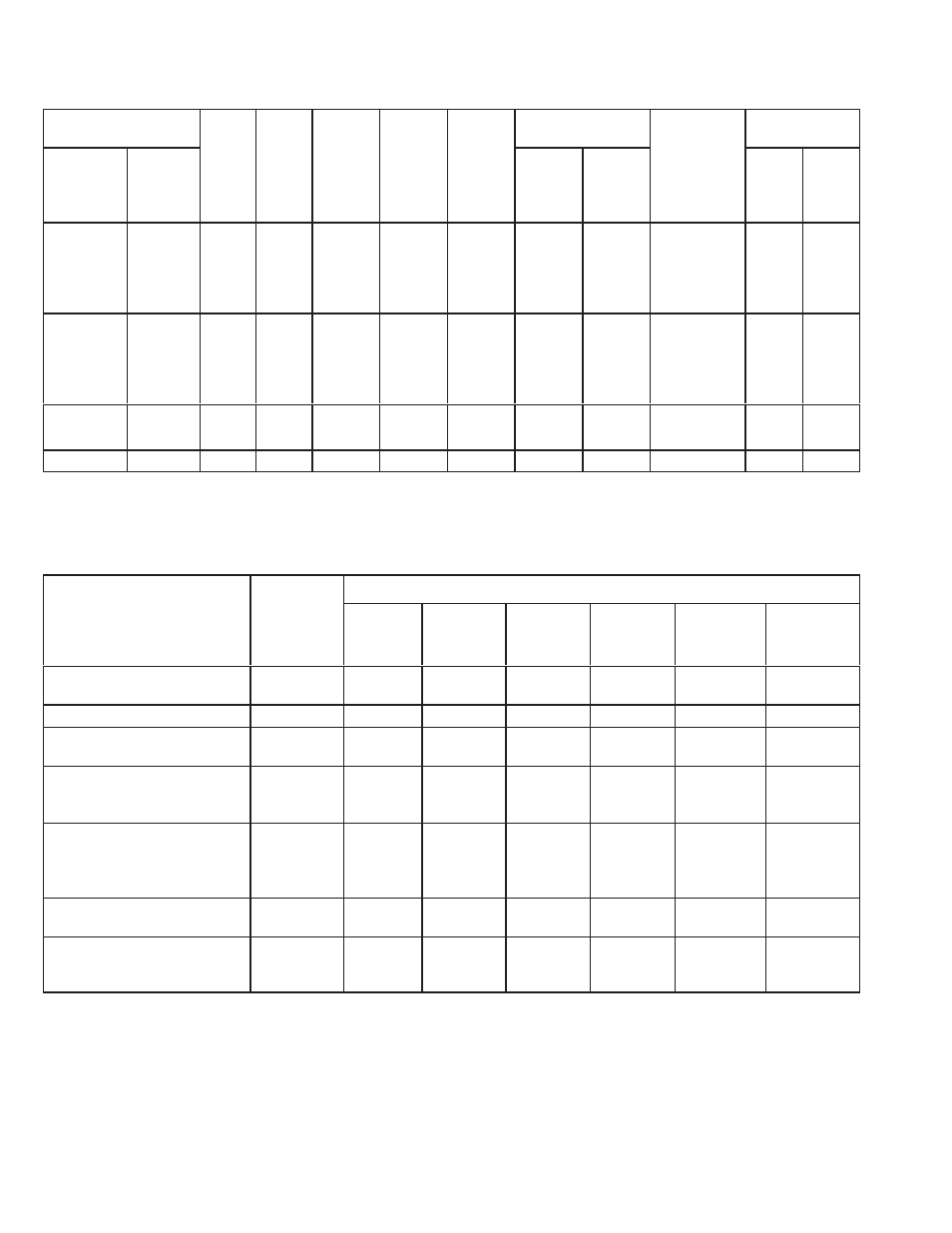

Table AĆ1. Controller Model Numbers

Model Number

Optional

Transf.

KVA

Enclosed Chassis

HP

VAC

(3)

AĆC

Amps

(RMS)

DĆC

Arm.

(Volts)

DĆC

Arm.

Amps

Avg.

DĆC

Field

Volts

Amp.

MAX

Power

Supply

Capacity

(2)

MAX

MIN

14C10

14C20

1/4

115

3.5

90

2.5

100

3.0

1000

40.0

0.50

1/3

115

5.2

90

3.7

100

3.0

1000

40.0

0.75

1/2

115

7.0

90

5.0

100

3.0

1000

40.0

1.50

3/4

115

10.5

90

7.5

100

3.0

1000

40.0

1.50

14C11

14C21

1/2

230

3.5

180

2.5

200

3.0

1000

40.0

1.50

3/4

230

5.2

180

3.7

200

3.0

1000

40.0

1.50

1

230

7.0

180

5.0

200

3.0

1000

40.0

2.00

1 1/2

230

10.5

180

7.5

200

3.0

5000

40.0

3.00

14C12

14C22

2

230

14.0

180

10.0

200

3.0

1

5000

40.0

5.00

3

230

21.0

180

15.0

200

3.0

1

5000

40.0

10.0

14C13

14C23

5

230

35.0

180

25.0

200

3.0

1

5000

40.0

10.0

1

Standard

2

Maximum permissible available symmetrical RMS fault current (amperes) with NEC or CEC external approved disconnect.

3

Does not include current required for Field Supply (if used).

Table AĆ2. Local Operator Control Faceplates

Specify

Operator's

Functions Provided

1

When Using A

MinPak Plus

Controller With:

Operator's

Control

Faceplate

Model

Start/

Stop

SpeedĆ

setting

Pot

TorqueĆ

setting

Pot

Run/

Jog

Selector

Forward/

Reverse

Selector

Automatic/

Manual

Selector

Blank Faceplate (Use with

Remote Station)

14C200

no

no

no

no

no

no

BasicFeatures

14C201

yes

yes

no

yes

no

no

BasicFeatures Plus ArmaĆ

tureĆReversing

14C202

yes

yes

no

yes

yes

no

BasicFeatures Plus AutoĆ

matic/Manual Modes of

Operation

14C203

yes

yes

no

yes

no

yes

BasicFeatures Plus ArmaĆ

tureĆReversing and AutoĆ

matic/Manual Modes of

Operation

14C204

yes

yes

no

yes

yes

yes

BasicFeatures Plus Torque

Control

14C205

yes

yes

yes

yes

no

no

BasicFeatures Plus ArmaĆ

tureĆReversing and Torque

Control

14C206

yes

yes

yes

yes

yes

no