Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 16

3:5

DANGER

THE USER IS RESPONSIBLE

FOR CONFORMING TO THE

NEC AND ALL OTHER APPLIĆ

CABLE LOCAL CODES WITH

RESPECT TO WIRING PRACĆ

TICES, GROUNDING, DISĆ

CONNECTS AND OVERCURĆ

RENT PROTECTION ARE OF

PARTICULAR IMPORTANCE.

FAILURE TO OBSERVE THIS

PRECAUTION COULD REĆ

SULT IN SEVERE BODILY

INJURYOR LOSS OF LIFE.

DANGER

THIS EQUIPMENT IS AT LINE

VOLTAGE WHEN AĆC POWER

IS CONNECTED.

DISCONĆ

NECT AND LOCKOUT ALL

UNGROUNDED

CONDUCĆ

TORS OF THE AĆC POWER

LINE. FAILURE TO OBSERVE

THESE PRECAUTIONS COULD

RESULT IN SEVERE BODILY

INJURYOR LOSS OF LIFE.

Ground the Controller and

Enclosure, the Motor and the

Operator's Control Station.

DANGER

CONNECT

THE

GROUND

WIRE BROUGHT IN WITH THE

INCOMING AĆC POWER LINE

TO

THE

CONTROLLER

GROUND POINT. CONNECT

AN APPROPRIATE EQUIPĆ

MENT GROUNDING CONDUCĆ

TOR UNBROKEN FROM THE

THE CONTROLLER GROUND

POINT, THE MOTOR FRAME,

THE TRANSFORMER ENCLOĆ

SURE IF USED, THE CONĆ

TROLLER ELECTRICAL ENĆ

CLOSURE, THE WIRING CONĆ

DUITS, AND THE OPERAĆ

TOR'S CONTROL STATION TO

AN APPROPRIATE GROUNDĆ

ING ELECTRODE. FAILURE

TO OBSERVE THESE PREĆ

CAUTIONS COULD RESULT IN

SEVERE BODILYINJURYOR

LOSS OF LIFE.

1. Locate the Controller ground

point provided.

2. Run asuitable equipment

grounding conductor unbroken

from the Controller ground point

(see step 1) to the plant ground

(grounding electrode). A ring

lug is recommended at the

ground point.

3. Connect asuitable grounding

conductor from each conduit to

this controller ground point.

4. Connect asuitable equipment

grounding conductor to the

motor frame, the transformer

enclosure if used, and the

controller enclosure. Run this

conductor unbroken to the

grounding electrode.

5. Connect the GND

(green/ground) wire brought in

with the incoming AĆC power line

to the controller ground point.

Ground the Optional

Faceplate

A ground wire is supplied as

standard with each Faceplate.

Connect the ground wire to abolt

on the underside of the cover and to

the controller chassis. Refer to

Figure 3Ć3A.

NOTE: Since the green wire is fixed

by the user on a faceplate bolt, the

installation should be performed

when the faceplate is fitted.

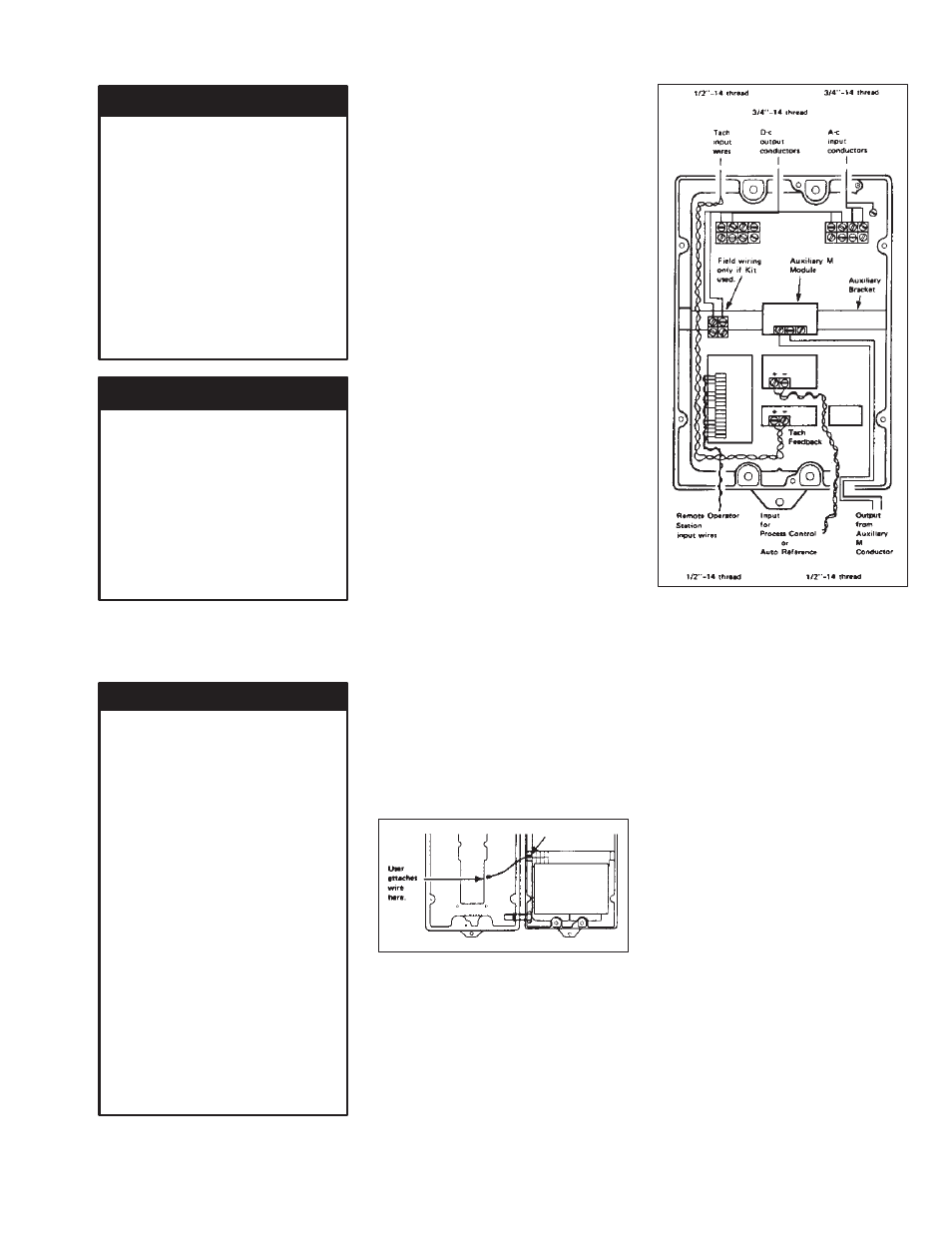

Figure 3Ć3A. Cover Ground Wire

General Wiring Practices

The Controller is designed for

Tachometer input wires, AĆC and

DĆC power entry at the top and

control and signal wiring to enter

from the bottom. See Figure 3Ć4.

Figure 3Ć4. Chassis Wells, Wire

Routing

Reference signal wiring should be

run in a separate steel conduit

isolated from all AĆC and DĆC power

and control. All reference signals

should be wired with either twisted

double or twisted triple conductor

wire, 2 twists per inch, stranded

copper, AWG No. 16, 600 VAC

rated, polyĆvinyl chloride insulation,

with a temperature range of 40 -

105_C (104 - 221_F). Signal wires

should not be run in parallel with

high voltage or electrically noisy

conductors. Always cross such

conductors at 90_.

Tachometer Feedback, Instrument

Interface and Voltage/Tachometer

Follower signal wiring should be run

in a separate conduit isolated from

all AĆC and DĆC power and logic

control. Wiring should be the same

as for the reference signals above.

For mounting with external

contactors and solenoids, coils