Rockwell Automation MinPak Plus DC Drive User Manual User Manual

Page 21

3:10

Wire the DĆC Motor to the

Controller

1. Size the motor armature circuit

conductors for the specific

controller rating and according

to applicable codes.

2. Run the DĆC motor armature

leads and the shunt field supply

leads (if a permanent magnet

field motor is not used). See

Figure 3Ć8 for the Motor

Armature Circuit Connection.

Refer to Wire the Field Supply"

in this manual for field supply

connections.

Install the Field Supply

The Field Supply Kit provides

fullĆwave field excitation for

shuntĆwound DĆC motors. It may be

optionally applied to controllers

from 1/4 thru 1 1/2 HP. (It is a

standard feature for 3 and 5 HP

MinPak Plus controllers.)

The Kit is an assembly consisting of

a terminal block (F1, F2), a field

power cube, two wiring harnesses,

bracket support and mounting

hardware. The user provides the

F1/F2 conductors to the drive motor.

No other equipment is required.

To install the Kit, follow these

procedures.

Step 1 - Mount Field Kit

a. Remove screws from 1TB.

b. Remove screws from the support

bracket.

c. Remove screw leads 32 and 132

from 2TB.

d. Remove the support bracket

from the unit.

e. Mount the Field Supply Kit onto

the unit.

f. Reinstall leads 32 and 132 onto

2TB.

g. Mount 1TB to the Field Supply

Kit.

Wire the Field Supply

DĆC field supply voltage and

maximum field amperes are listed in

Table 2Ć1.

Step 1 - Wire Field Supply Power

Cube

Wire from the field supply power

cube to terminals 51 and 52 on 2TB

as shown in Figure 3Ć9.

AĆC

AĆC

+

2 TB

51

52

F1 F2

3 TB

To

F1, F2

on motor

Figure 3Ć9. Connecting Field

Supply.

Step 2 - Ro ute Wires and F1/F2

Connection

The userĆsupplied field wiring

conductors should be drawn into

the chassis. Route them as

indicated in Figure 3Ć3. Move them

to the upper screws on 3TB and

connect F1/F2 according to the

label or Figure 3Ć9.

Wire the Speed Reference

Circuit

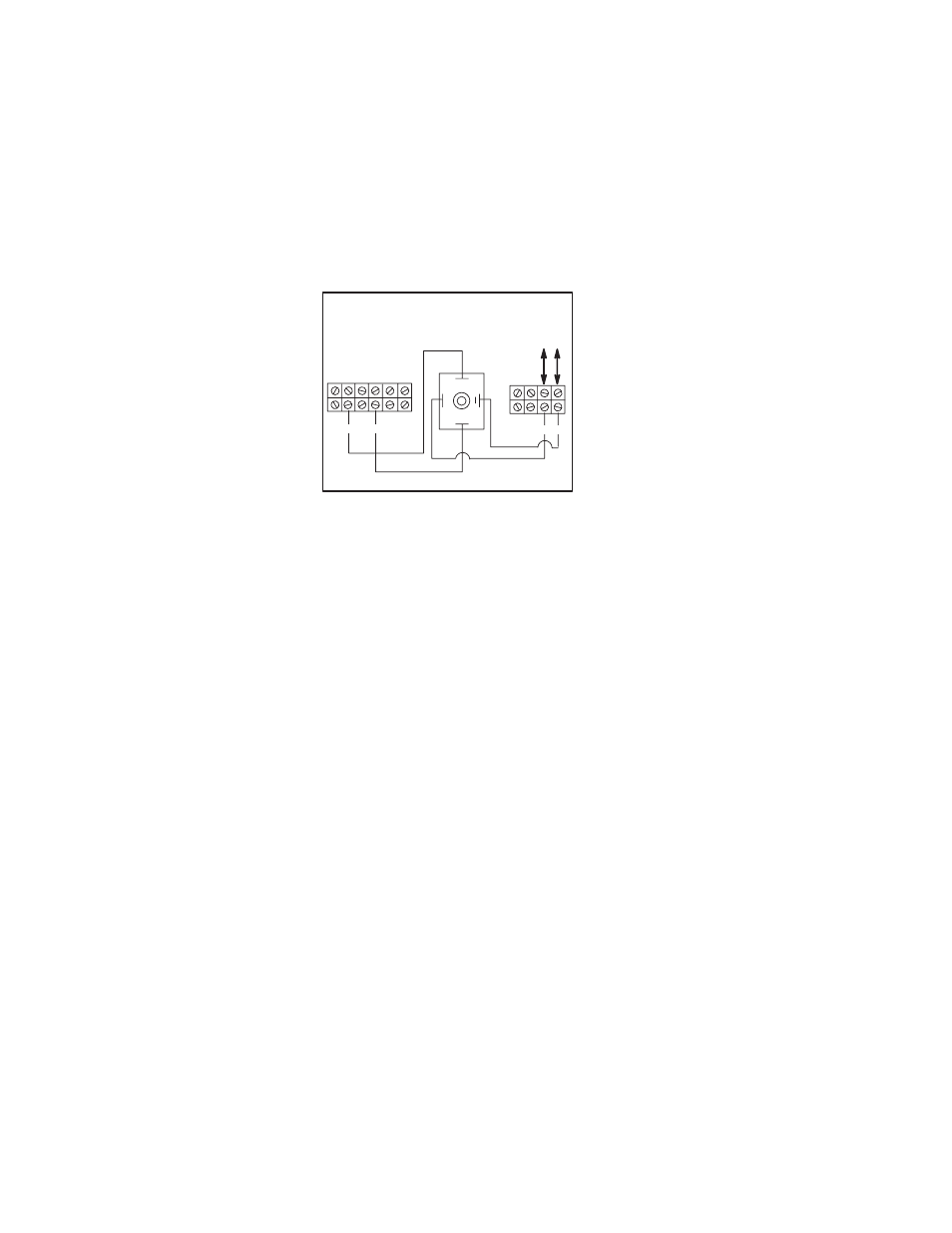

When only a Manual Operator's

Speed Pot Reference function is

utilized, the circuit shown in Figure

3Ć10 should be followed.

In this configuration (see Figure

3Ć10), the J4 jumper on the

Regulator Board is NOT to be cut,

the reference input is through

terminal 426 to the LVTU. The J4

Jumper is only removed when the

reference is brought in to terminal

126. Lead 126 is not to be taken

outside of the cabinet as it is not

buffered.

Reliance offers four Reference Kits

for Automatic Process Following.

These kits are:

1. Voltage/Tachometer Follower Kit,

M/N 14C223.

2. Instrument Interface/Preset

Speed Kit, M/N 14C222.

3. Dancer Follower Kit,

M/N 14C230.

4 Dancer Position kit, M/N 14C233.

These Kits can be used as

Automatic Reference Followers with

or without a Manual optional

function. If used without a Manual

option function, as described

above, the reference circuit for

these kits is setĆup as shown in

Figure 3Ć11. If the Automatic

Reference Kits are to be used with a

Manual optional function as

described above, the reference

circuit for these kits is setĆup as

shown in Figure 3Ć12.