Rockwell Automation 57C329 Remote I/O Communications, AutoMax User Manual

Page 120

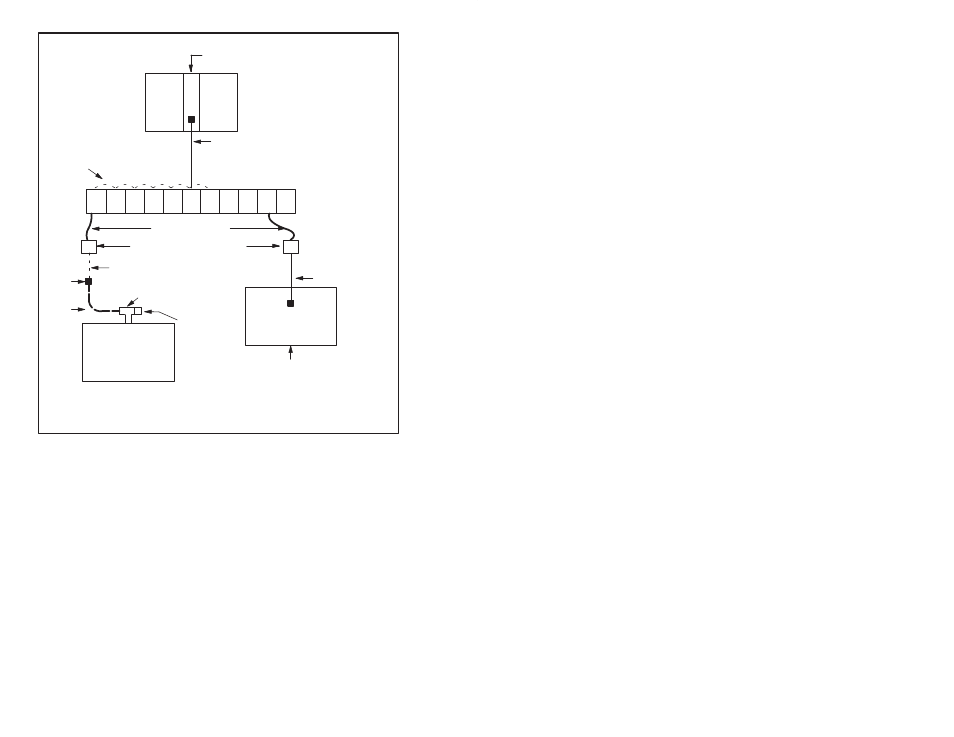

KĆ2

1

2 3

4

5

6

7 8

9 10 P/S

Remote I/O Communications Module

AutoMax Rack

Drop Cable (M/N 57C366)

Hub (Rack/Power

TwistedĆ

Pair Wire

FiberĆOptic Cable

StandĆAlone Transceiver

(M/N 57C365)

Drop Cable

(M/N 57C366)

AutoMax Rack containing

Supply M/N 57C368

containing 10

transceivers

M/N 57C367)

Master

Remote I/O Head, Remote Drive

Balun

TwistedĆPair Wire

Tee Adapter

. . .

Terminating

Load

Coax

Cable

(Slave Drop)

(Slave Drop)

Interface Head or

Personal Computer containing

PC Link Interface module

Remote I/O Communications

Module or Shark Rack

containing Shark Interface Module

Figure K1.1 Ć FiberĆOptic Remote I/O Network

As shown in the above figure, a StandĆAlone Transceiver is required

at each slave drop on the network. A StandĆAlone Transceiver is

required at the master rack only when this rack and the hub cannot

be located together in the same cabinet. The transceiver performs

the optical conversion of electrical data signals from the Network

module to the network and the electrical conversion of optical data

signals from the network to the Network module.

Each drop is connected by a fiberĆoptic link to another transceiver

mounted in a rack. Up to 10 transceivers can be mounted in the

transceiver rack, also called a hub". All communication between

drops takes place in the transceiver rack. The optical signals

received by any transceiver in the rack are converted into electrical

signals and propagated to all other transceivers in the rack via

twistedĆpair wire connections. Each transceiver then converts the

electrical signals to optical signals and retransmits them to its

corresponding drop.