Wiring the terminal block – Rockwell Automation 1763 MicroLogix 1100 Programmable Controllers User Manual User Manual

Page 44

Publication 1763-UM001D-EN-P - March 2011

42 Wiring Your Controller

•

Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

•

Separate input wiring from output wiring.

•

Label wiring to all devices in the system. Use tape, shrink-tubing, or

other dependable means for labeling purposes. In addition to labeling,

use colored insulation to identify wiring based on signal characteristics.

For example, you may use blue for DC wiring and red for AC wiring.

Wiring the Terminal Block

The MicroLogix 1100 controllers have screw-cage clamps on the input and

output terminal blocks. With screw-cage clamp terminal blocks, there is no

need to attach additional hardware such as a spade lug to the wire, or use a

finger-safe cover.

To wire the terminal block:

1. Strip the end of the wire.

The recommended length for the stripped end of the wire is 11.0 mm

(0.440 in.).

2. Insert it into an open clamp.

3. Using a small, flat-blade screwdriver, tighten the terminal screw. To

ensure that the wire conductor is secured inside the clamp, tighten it to

the rated torque, 0.56 Nm (5.0 in-lb).

The diameter of the terminal screw head is 5.5 mm (0.220 in.).

TIP

Do not run signal or communications wiring and

power wiring in the same conduit. Wires with

different signal characteristics should be routed by

separate paths.

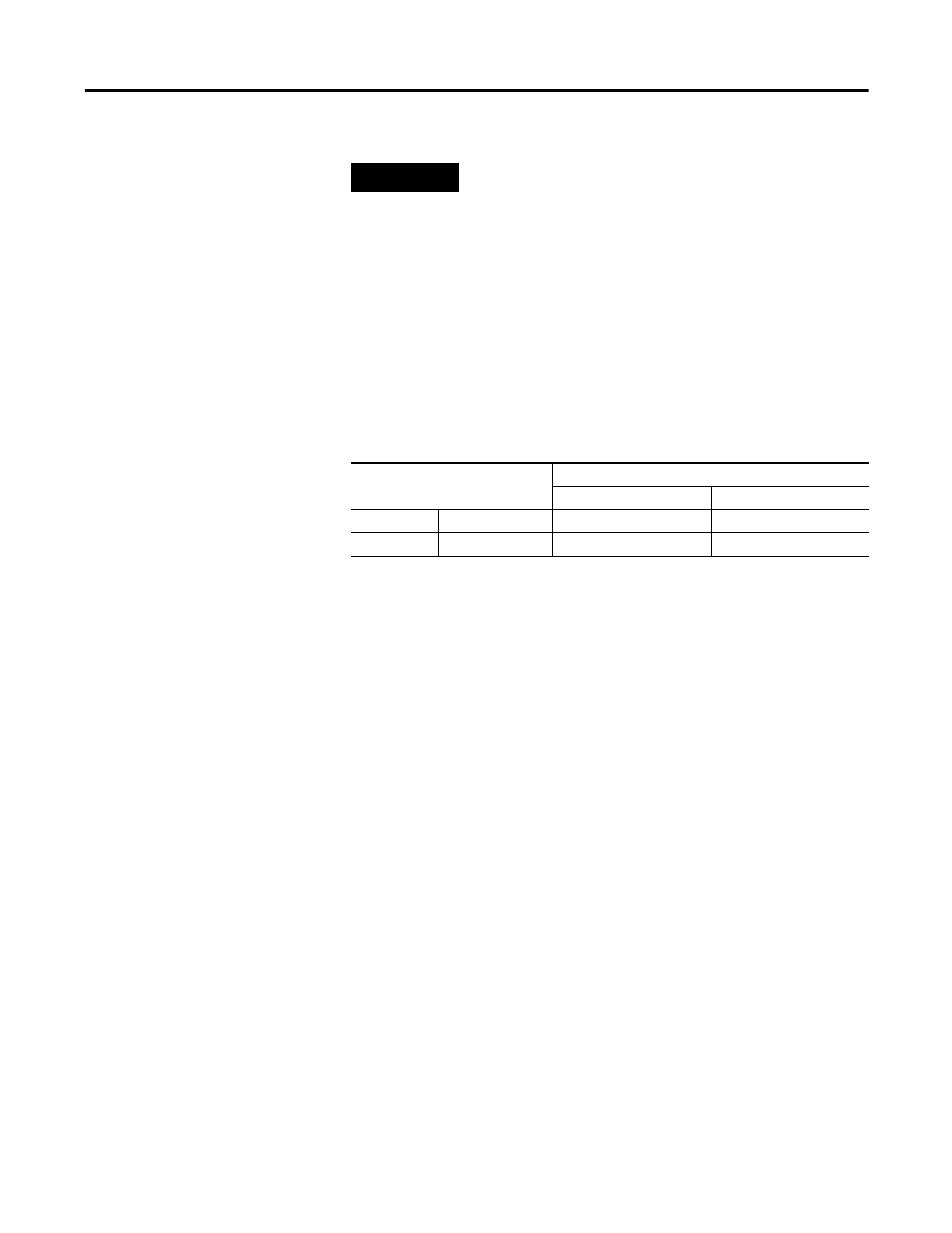

Wire Requirements

Wire Type

Wire Size (2 wire maximum per terminal screw)

1 wire per terminal

2 wire per terminal

Solid

Cu-90°C (194°F)

#12 to #20 AWG

#16 to #20 AWG

Stranded

Cu-90°C (194°F)

#14 to #20 AWG

#18 to #20 AWG

Wiring torque = 0.56 Nm (5.0 in-lb) rated