Grounding guidelines – Rockwell Automation 1747-L40 SLC 500 Fixed Hardware Style User Manual

Page 42

Chapter 2

System Installation Recommendations

2–3

In solid–state control systems, grounding helps limit the effects of noise due

to electromagnetic interference (EMI). The grounding path for the controller

and its enclosure is provided by the equipment grounding conductor.

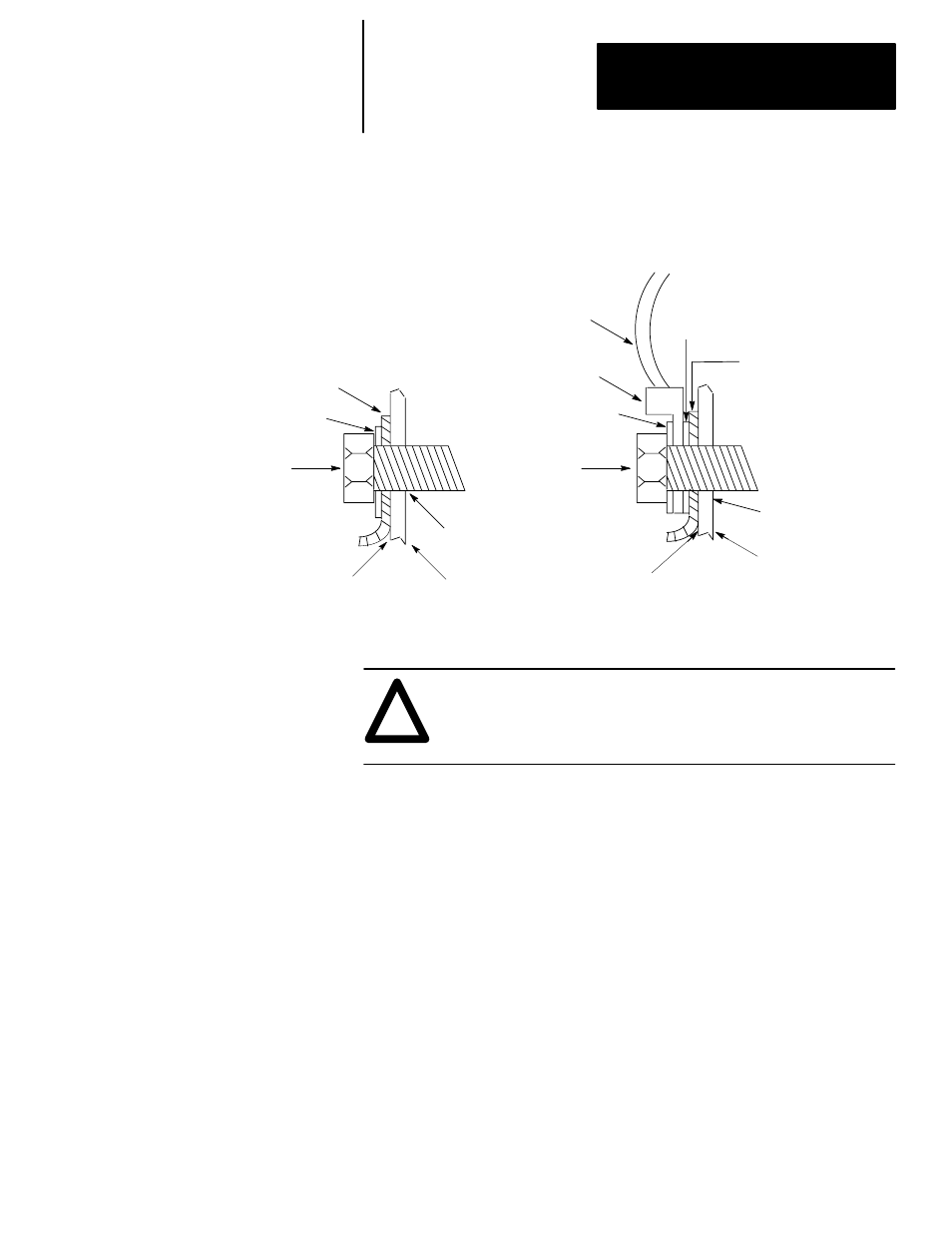

Chassis

Mounting Tab

#10 AWG to

Ground Bus

Chassis Mounting Tab

Ground

Lug

Size 12 Internal

Star Washer

Tapped Hole

(Minimum of Three

Threads)

Metal Panel

(Must be connected to earth

ground.)

Scrape paint off panel to insure

electrical connection between chassis

and grounded metal panel.

Tapped Hole

(Minimum of Three

Threads)

Size 12 Internal

Star Washer

Scrape paint off panel to insure

electrical connection between chassis

and grounded metal panel.

Normal Electrical Noise Conditions

Severe Electrical Noise Conditions

Metal Panel

(Must be connected to

earth ground.)

Size 10 or 12

Hardware Screw

Size 10 or 12

Hardware Screw

Size 12 Internal

Star Washer

!

ATTENTION: The SLC 500 controller, other control devices,

and the enclosure must be properly grounded. All applicable

codes and ordinances must be observed when wiring the

controller system.

Ground connections should run from the chassis and power supply on each

controller and expansion unit to the ground bus. Exact connections will

differ between applications. An authoritative source on grounding

requirements for most installations is the National Electrical Code. Also,

refer to Allen–Bradley Programmable Controller Grounding and Wiring

Guidelines, Publication Number 1770–4.1.

In addition to the grounding required for the controller and its enclosure, you

must also provide proper grounding for all controlled devices in your

application. Care must be taken to provide each device with an acceptable

grounding path.

Grounding Guidelines