Start-up routines, Start-up, For i – Rockwell Automation 20A PowerFlex 70 Adjustable Frequency AC Drive User Manual

Page 46

46

Rockwell Automation Publication 20A-IN009D-EN-P - June 2013

PowerFlex 70 Adjustable Frequency AC Drive

Start-up Routines

The PowerFlex 70 is designed so that startup is simple and efficient. If you have

an LCD HIM, two start-up methods are provided. Select the desired start-up

routine needed for the application:

• S.M.A.R.T. Start

This routine lets you quickly set up the drive by programming values for

the most commonly used functions (see

• Assisted Startup

This routine prompts you for information needed to start up a drive for

most applications, such as line and motor data, commonly adjusted

parameters, and I/O. With enhanced control, two levels of assisted startup

are available: basic and detailed (see

Running an Assisted Startup on

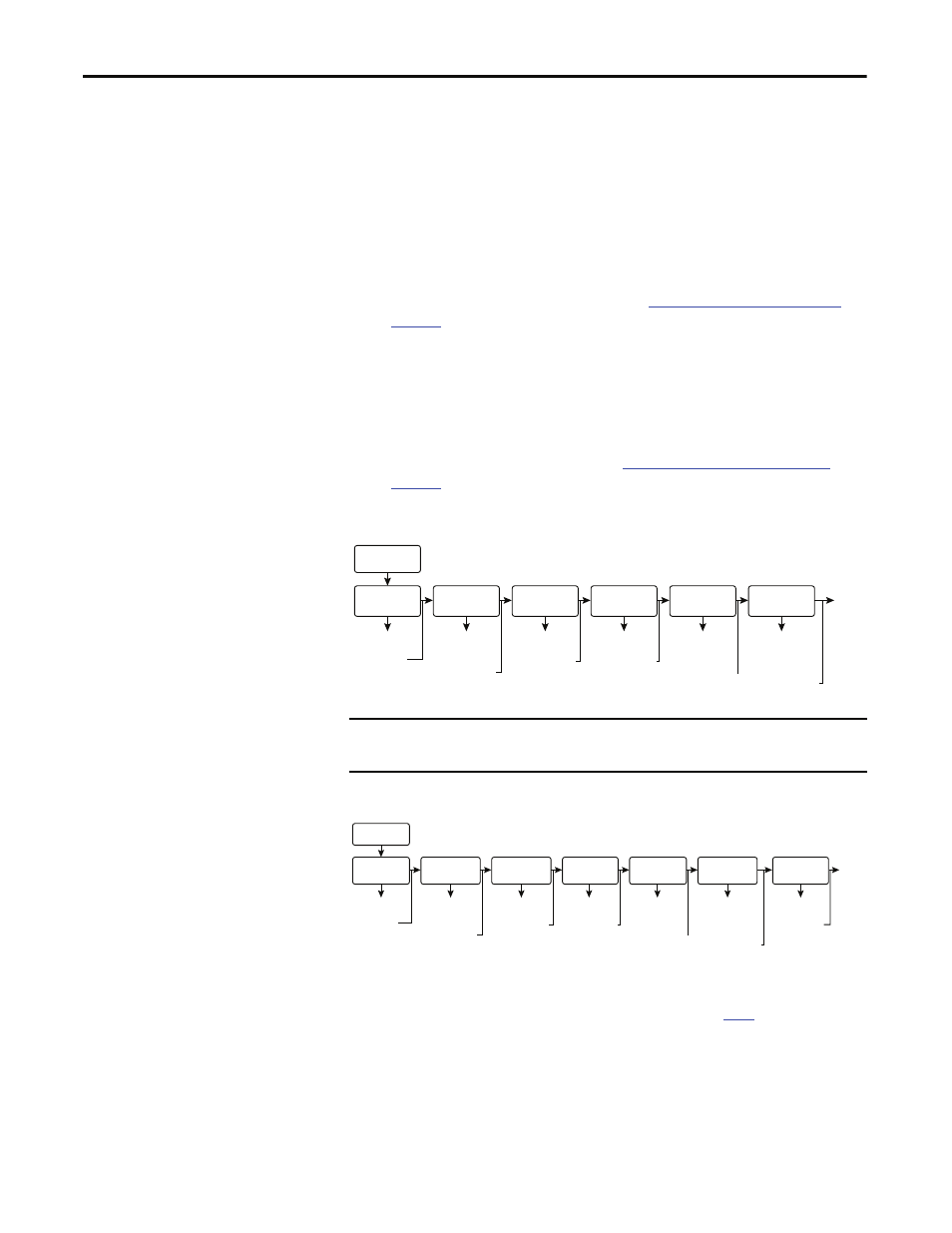

Figure 15 - Standard Control Start-up Menu

Figure 16 - Enhanced Control Start-up Menu

(1)

During motor tests and tuning procedures, the drive can modify certain parameter values for proper start-up operation. These

values are then reset to their original values when startup is complete. The affected parameters are: 053, 080, 276, 278, and

361…366. If power is removed from the drive during the tests without aborting the auto-tune procedure, these parameters may

not reset to their original value. If this situation occurs, reset the drive to factory defaults (see

) and repeat the start-up

procedure.

(2)

Only in Detailed Startup mode.

IMPORTANT

Power must be applied to the drive when viewing or changing parameters.

Previous programming can affect the drive status when power is applied.

Configure for

Alternate Input

Voltage

Input Voltage

Start-Up

Enter Motor NP

Data, Stop Mode,

Accel/Decel

Ramp Times

Motor Data and

Ramp Times

Optimize Torque

and

Verify Direction

Motor Tests

(1)

Set Min/Max

Speed and

Direction Control

Speed Limits

Configure

Source, Value

and Scale for

Speed References

Speed Control

Start/Stop/I/O

Configure

Control Method

(2 Wire/3 Wire), I/O,

Digital Inputs/Outputs

and Analog Outputs

Done /

Exit

Main Menu:

Configures

Motor Control

Method

Motor Control

Select

Start-Up

Enter Motor NP

Data, Stop Mode,

Accel/Decel

Ramp Times

Motor Data and

Ramp Times

Optimize Torque

and

Verify Direction

Motor Tests

(1)

Set Min/Max

Speed and

Direction Control

Speed Limits

Configure

Source, Value

and Scale for

Speed References

Speed/Torque

Control

Start/Stop/I/O

Configure

Control Method

(2 Wire/3 Wire), I/O,

Digital Inputs/Outputs

and Analog Outputs

Application

(2)

Configure

for Specific

Application

Done /

Exit

Main Menu: