Step 5: start-up checklist, Prepare for drive startup – Rockwell Automation 20A PowerFlex 70 Adjustable Frequency AC Drive User Manual

Page 41

Rockwell Automation Publication 20A-IN009D-EN-P - June 2013

41

PowerFlex 70 Adjustable Frequency AC Drive

Table 20 - Encoder Specifications

Step 5: Start-up Checklist

• This checklist supports the basic start-up menu option. See

for information on other start-up routines.

• A HIM is required to run the basic start-up routine.

• The basic start-up routine can modify parameter values for analog and

digital I/O. Refer to

Common I/O Programming Changes on page 48

.

Prepare For Drive Startup

1. Verify the input supply voltage.

2. Check the output wiring.

3. Check the control wiring.

4. Connect a HIM to DPI Port 1 or 2.

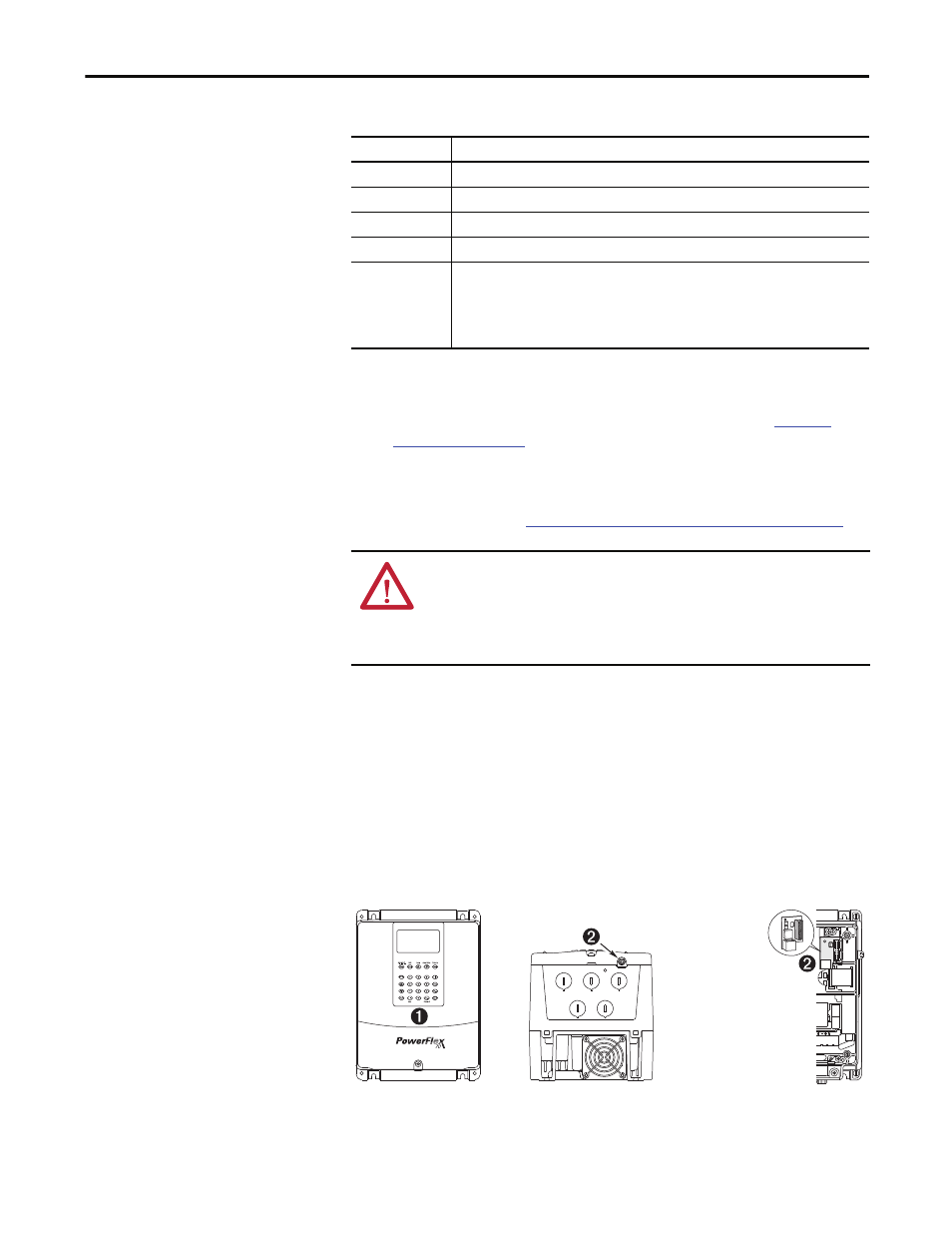

Figure 14 - DPI Ports 1 and 2

Topic

Description

Type

Incremental, dual-channel

Supply

5V/12V Configurable ±5%

Quadrature

90° ±27°

Duty Cycle

50% +10%

Requirements

Encoders must be line driver type, quadrature (dual channel) or pulse (single channel), single-

ended or differential and capable of supplying a minimum of 10 mA per channel. The encoder

interface board accepts 5V or 12V DC square-wave with a minimum high state voltage of 3.5V

DC (5V mode) and 7.0V DC (12V mode). Maximum low state voltage is 1V DC (for both 5V and

12V modes). Maximum input frequency is 250 kHz.

ATTENTION: Power must be applied to the drive to perform the following

start-up procedure. Some of the voltages present are at incoming line potential.

To avoid electric shock hazard or damage to equipment, only qualified service

personnel can perform the following procedure. Thoroughly read and

understand the procedure before beginning.

CTRL BD

GND

Optional Service

Connection Board

(SK-M9-SCB1)

provides temporary

DPI connection with

drive cover removed.