Hardware enable circuitry (only enhanced control) – Rockwell Automation 20A PowerFlex 70 Adjustable Frequency AC Drive User Manual

Page 39

Rockwell Automation Publication 20A-IN009D-EN-P - June 2013

39

PowerFlex 70 Adjustable Frequency AC Drive

Hardware Enable Circuitry (only enhanced control)

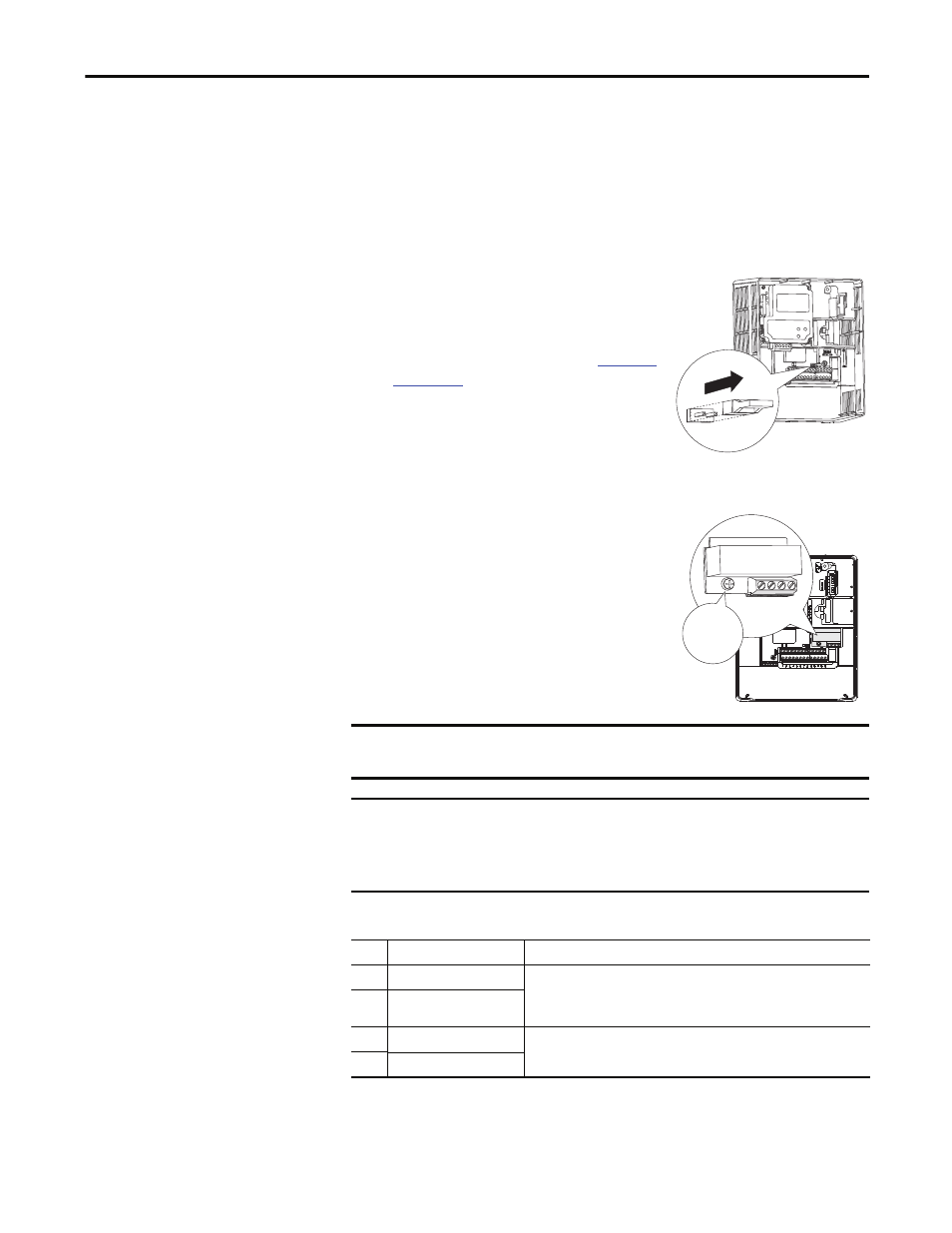

By default, you can program a digital input as an enable input. The status of this

input is interpreted by drive software. If the application requires the drive to be

disabled without software interpretation, a hardware enable configuration is

used. To use the hardware enable configuration, remove the enable jumper

(ENBL JMP) and wire the enable input to Digital In 6 (see below).

1. Remove the drive cover.

2. Locate and remove the enable jumper on

the main control board (see the diagram).

3. Wire enable to Digital In 6 (see

).

Safe Torque Off Board Option (only enhanced control)

The optional PowerFlex Safe Torque Off board,

when used with suitable safety components,

provides protection according to EN 954-1:1997;

Category 3 for safe off and protection against

restart. The PowerFlex safe off option is just one

safety control system. All components in the

system must be chosen and applied correctly, to

achieve the desired level of operator safeguarding.

Table 18 - Terminal Description

IMPORTANT

The drive enable digital input is a solid state circuit. The safety outputs on the

safety module must not be configured for pulsed/safety pulse test.

IMPORTANT

The drive ships with the hardware enable jumper (ENBL JMP) installed. You

must remove the jumper if you are using the DriveGuard® Safe Torque Off

option. If you do not remove the jumper, the drive faults when a start

command is issued.

No.

Signal

Description

1

Monitor - N.C.

Normally closed contacts for monitoring relay status.

Maximum Resistive Load: 250V AC / 30V DC / 50 VA / 60 W

Maximum Inductive Load: 250V AC / 30V DC / 25 VA / 30 W

2

Common - N.C.

3

+24V DC

Connections for user supplied power to energize coil.

4

24V Common

1

2

3

4

0.8…1.1 N•m

(7…10 lb•in)

20A-DG01