Coolant considerations, Considerations affecting all frame sizes, Coolant considerations -16 – Rockwell Automation 20M LPM15 Liquid-Cooled Adjustable Frequency AC Drive FRN 2.xxx User Manual

Page 28

1-16

Installation/Wiring

3. Connect a suitable grounding conductor to the motor frame and the

remote control station (if used). Run each conductor unbroken to earth

ground. When adding more than one grounding conductor wire to a

single chassis ground, twist the conductors together. Tighten these

grounding connections to the proper torque as shown in

.

4. Close the door of the enclosure.

Coolant Considerations

LPM15 drives use o-ring face seal fittings for connection to the coolant

supply. The coolant is typically clean water with a corrosion inhibitor as

described in this section.

Considerations Affecting all Frame Sizes

LPM15 drive coolant connections are made with o-ring face seal fittings.

The copper tube running from the heatsink to the o-ring fittings is covered

with closed cell foam insulation.

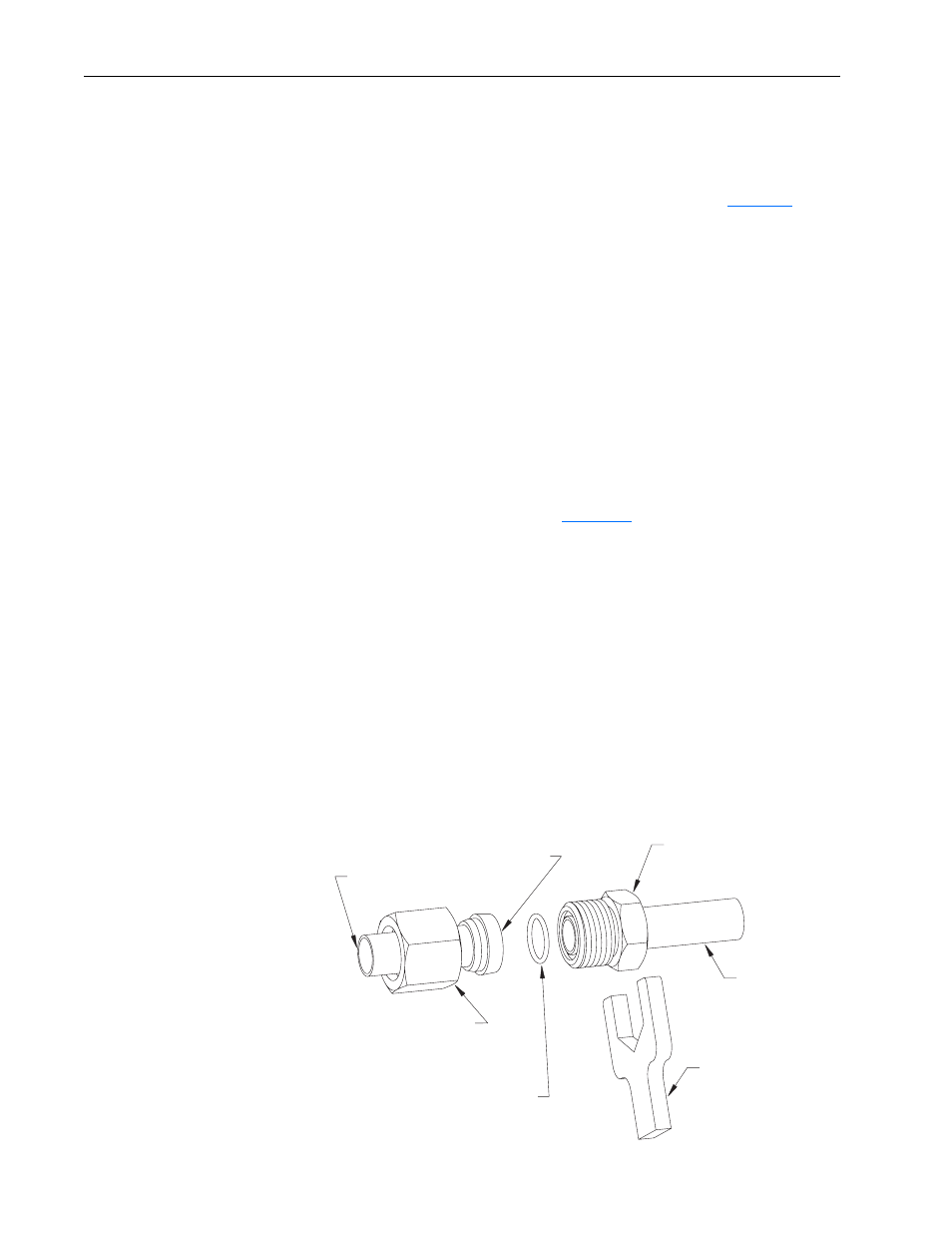

The mating connection is shown in

. The mating process includes

the following steps:

1. Coat the o-ring with the o-ring lubricant. The goal is a thin film covering

the entire o-ring surface. Avoid excess globs of lubricant.

2. Insert the o-ring into the o-ring groove in the external thread-side fitting

on the user side. Avoid any twisting of the o-ring.

3. Assemble the fittings and tighten to a torque of 37 to 45 N-m (or 27 to 33

lb.-ft.). Use a backup wrench on the user side fitting to avoid twisting the

drive side tubing.

Figure 1.8 Mating Connection

DRIVE SIDE CONNECTION

USER SIDE CONNECTION

ORFS Nut

(Parker p/n 10-BL-B)

ORFS Braze Adapter

(Parker p/n 10-LOHB3-B)

ORFS Braze Sleeve

(Parker p/n 10-TL-B)

O-Ring, Neoprene

(Parker p/n 2-016-CO873-70)

O-Ring Lubricant

(Parker p/n 884-2GRAMS-LUBE)

5/8-inch O.D.

Copper Tube

Backup Wrench

(Use to prevent twisting

during nut tightening.)

5/8-inch O.D.

Copper Tube