I/o wiring recommendations, I/o wiring recommendations -13 – Rockwell Automation 22F PowerFlex 4M User Manual FRN 1.xx - 2.xx User Manual

Page 23

Installation/Wiring

1-13

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Important points to remember about I/O wiring:

•

Always use copper wire.

•

Wire with an insulation rating of 600V or greater is recommended.

•

Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

Important: I/O terminals labeled “Common” are not referenced to the

safety ground (PE) terminal and are designed to greatly

reduce common mode interference.

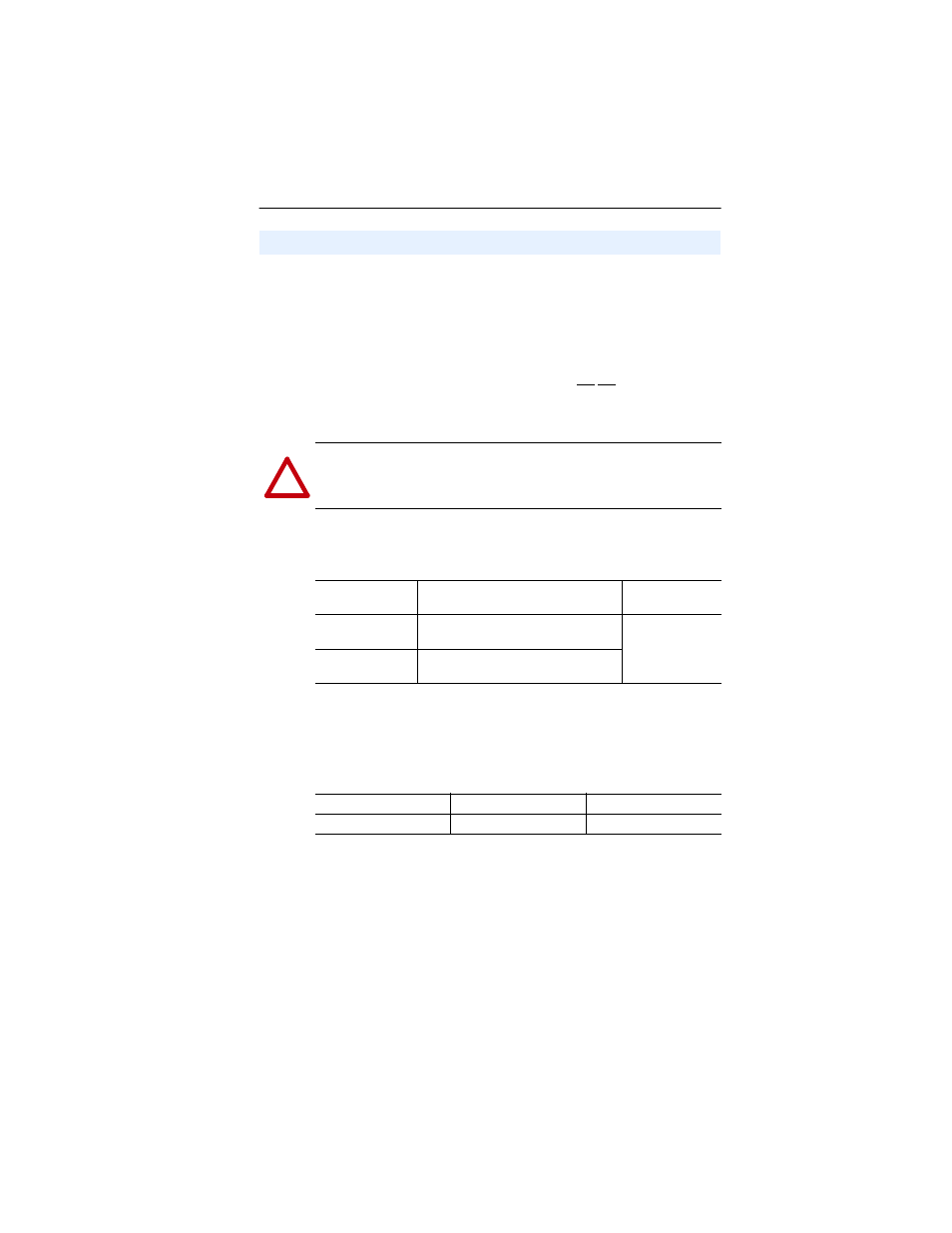

Control Wire Types

Table 1.G Recommended Control and Signal Wire

(1)

I/O Terminal Block

Table 1.H I/O Terminal Block Specifications

Maximum Control Wire Recommendations

Do not exceed control wiring length of 30 meters (100 feet). Control

signal cable length is highly dependent on electrical environment and

installation practices. To improve noise immunity, the I/O terminal block

Common must be connected to ground terminal/protective earth. If using

the RS485 (DSI) port, I/O Terminal 16 should also be connected to

ground terminal/protective earth.

I/O Wiring Recommendations

!

ATTENTION: Driving the 4-20mA analog input from a voltage

source could cause component damage. Verify proper configuration

prior to applying input signals.

Wire Type(s)

Description

Minimum

Insulation Rating

Belden 8760/9460

(or equiv.)

0.8 mm

2

(18AWG), twisted pair, 100%

shield with drain.

(1)

(1)

If the wires are short and contained within a cabinet which has no sensitive circuits,

the use of shielded wire may not be necessary, but is always recommended.

300V

60 degrees C

(140 degrees F)

Belden 8770

(or equiv.)

0.8 mm

2

(18AWG), 3 conductor, shielded for

remote pot only.

Maximum Wire Size

(1)

(1)

Maximum/minimum sizes that the terminal block will accept - these are not

recommendations.

Minimum Wire Size

(1)

Torque

1.3 mm

2

(16 AWG)

0.2 mm

2

(24 AWG)

0.5-0.8 N-m (4.4-7 lb.-in.)