Rockwell Automation 48MS MultiSight Vision Sensor User Manual

Page 34

MultiSight™ User Manual

Start-up

34

10000000877(02)

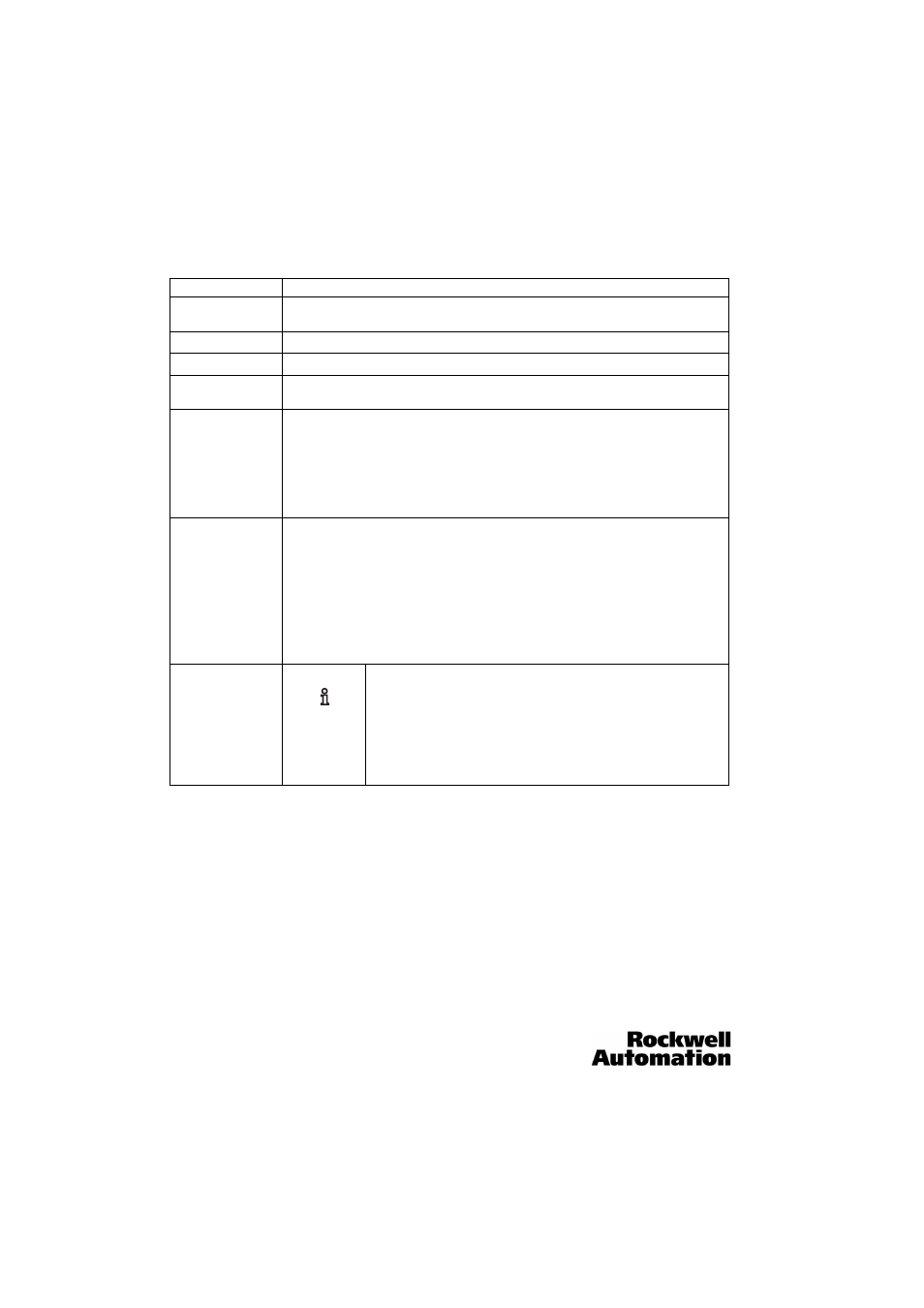

Parameter

Description

Shutter x.xx ms

Exposure time: slide for setting shutter value manually. Increase to brighten image; decrease to darken image. The

shutter speed can also be adjusted by clicking on the number and typing a new value into the pop-up window.

Trigger Delay (ms)

Time between trigger and exposure/evaluation in 0-3000 ms (see “Configurable Delays” on page 40).

Output Delay (ms)

Time between trigger and availability of result on OUT1 and OUT2 in 0-3000 ms.

Output Duration (ms)

Time in 0-3000 ms that the output state is maintained. Please review the notes in the Configurable Delays section

on page 40).

Output Active

HIGH or LOW = inverting of OUT1 and OUT2.

HIGH

Passing evaluation results in the PNP output turning ON (sourcing current). Failing evaluation results in

the output turning OFF (normally open).

LOW

Passing evaluation results in the PNP output turning OFF. Failing evaluation results in the output turning

ON (normally closed).

The result indicators in the software do not change with this parameter (i.e., green dot always indicates passing

evaluation).

Threshold Min. and Max.

Threshold values define the minimum and/or maximum evaluation score for the inspection to pass. Can be

adjusted by the sliders or by clicking on the threshold number and typing a new value into the pop-up window.

Values = 0.00…1.00 in 0.05 increments (35% conformity threshold would be entered as ‘0.35’). The threshold

values are depicted by small vertical black lines on the detector results bar graph when the sensor is in run mode.

Both thresholds can be used at the same time and in this case a section in the middle of the results bar graph can

be defined as the “Good zone.” (PASS output when Threshold Min. is exceeded AND Threshold Max. is not

exceeded.)

Setting the Threshold Max below the Threshold Min is not possible.

Threshold Min. and Max.

(cont.)

In practice, “Good” parts are not 100% identical with the pattern taught. Slight differences

in position or fluctuations in light level mean that they do not conform completely to the

reference pattern. “Bad” parts should differ from “Good” parts in as many characteristics or

as large a part of the pattern area as possible. If a pattern has been taught using a “Good”

part, it must first be established what degree of conformity with the pattern is achieved

with various “Bad” parts (reference the length of bar graph for results). The degrees of

conformity with the pattern achieved with various “Good” and “Bad” parts should be as far

apart as possible. The threshold value should be set approximately at the center of this

difference between the “Good” and “Bad” parts.