Periodical inspection, Inspection procedures – Yamato Scientific SQ 510 Autoclave, Sterilizers User Manual

Page 64

61

Periodical Inspection

Periodical Voluntary Inspection of Small-sized Pressure Vessel

Inspection procedures

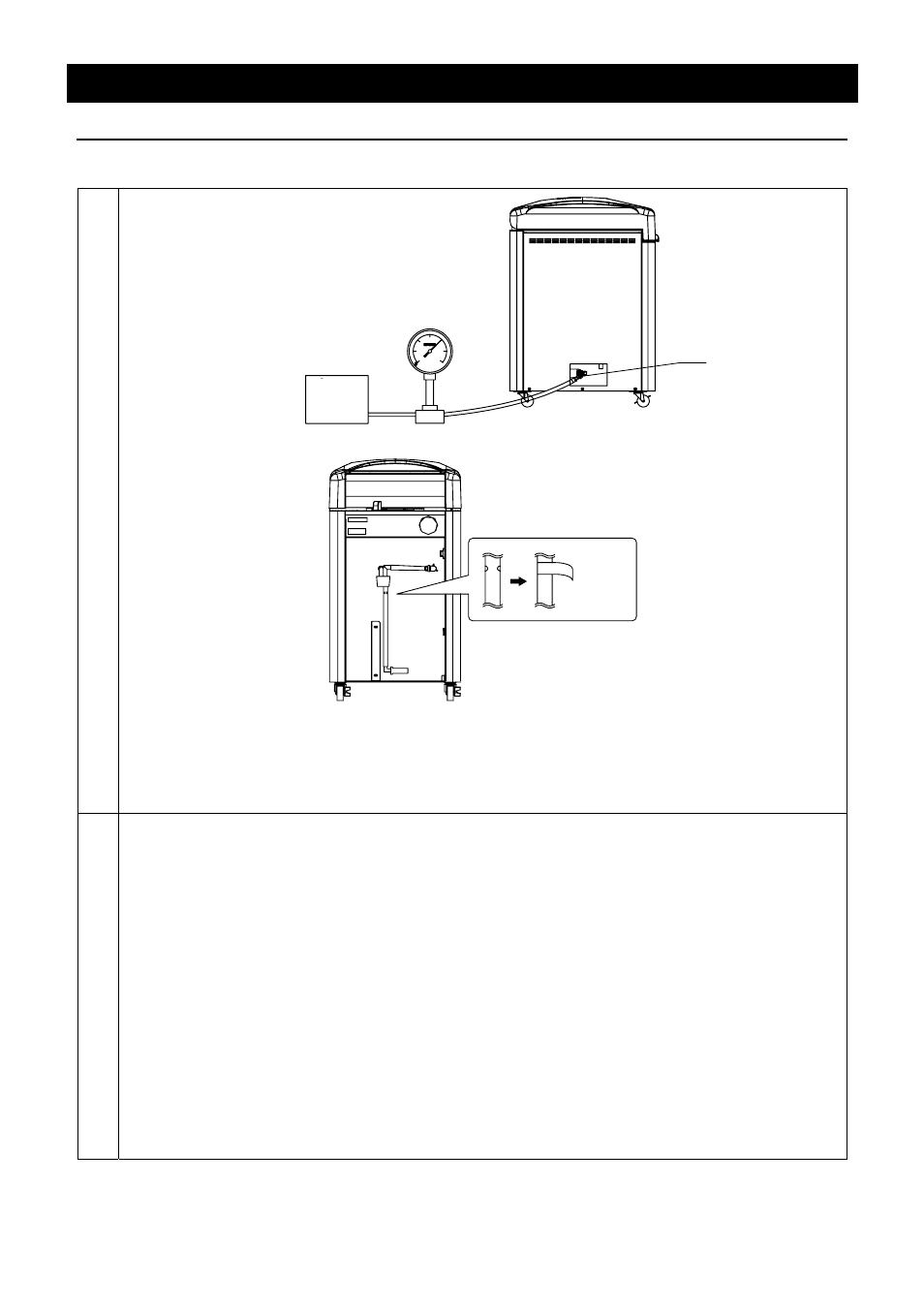

W

ater leak o

n solen

oi

d valve/

exha

ust valve

①

Close the drain valve as soon as the safety valve operates.

穴を塞ぐ

②

Pressurize the chamber inside. When the corrected pressure gauge reads 0.05MPa, 0.1MPa

and 0.15MPa, compare the readings between the corrected pressure gauge and the pressure

gauge on the main unit.

The tolerance of pressure accuracy compared should be within ±0.005 MPa. If it is beyond this

range, replace the pressure gauge.

Te

mperat

ure a

ccuracy

Check the temperatue accuracy by using either of following methods.

①

Fix a corrected temperature sensor (a recorder attached) or maximum thermometer near the

chamber temperature sensor inside the chamber. Perform the sterilizing operation at a preset

temperature of 135℃ with no load. Compare the temperature inside the chamber displayed

on the equipment with that indicated by the corrected thermometer. The temperature should

be between 135 and 137℃ to the preset temperature of 135℃. Use the service plug (internal

thread of R1/4) to fix the temperature sensor.

②

Perform sterilization and compare the pressure and temperature at sterilization process. The

relation between the temperature inside the chamber and saturated pressure under the

atmosphere of 1013 hPa are as follows.

115℃: 0.068MPa, 133℃: 0.187MPa

121℃: 0.104MPa, 134℃: 0.202MPa

126℃: 0.138MPa, 135℃: 0.212MPa

131℃: 0.170MPa, 136℃: 0.221MPa

132℃: 0.171MPa, 137℃: 0.231MPa

If parts replacement, repair or correction is difficult to be done by yourselves, contact the selling office

where you purchased or our sales office.

Pressure

device

Close

Opening is

blocked.