Care and use manual – Waters IC-Pak Ion Exclusion Columns User Manual

Page 5

[ Care and Use ManUal ]

5

Waters IC-PAK

™

Ion Exclusion Columns

c. Eluent Preparation

10 mM Octanesulfonic Acid Concentrate

1. To a 254 mL beaker add 2.163 g of the sodium salt of

octane sulfonic acid (98% Aldrich) and dissolve in 100 mL

Milli-Q water.

2. Add 100 mL of precleaqned cation exchange resin in the

H+ form (BloRad AG 50W-X12, 200-400 mesh, or equiva-

lent) and stir in the resulting slurry for 10 minutes.

3. Filter the resin, rinsing with approximately 800 mL of

Milli-Q water, into a one liter volumetric flask. Dilute up to

the mark with Milli-Q water.

Note: This 10 mM oc tanesuffonic acid solution istable for at least

one month.

1 mM Octanesulfonic Acid Eluent (pH3)

1. Into a one-liter volumetric flask add 100 mL of the octane-

sulfonic acid concentrate.

2. Fill the flask to the mark with Milli-Q water and mix

thoroughly.

3. Filter and degas through a 0.45 µm HA filter.

The H+ ion from the acid influences the separation. The acid’s

counter-anion has no effect but to after the background conductivity.

Thus, other strong acids can be substituted for octanesulfonic acid.

Note: Acid Normality should be kept constant.

Weak organic acids can also be detected by direct UV absorption in

the 205 nm to 215 nm range.

d. Standard Preparation

1. Prepare 1000 ppm stock standards from their sodium salts

2. For this working standard, dilute:

0.1 mL of 1000 ppm Fluoride

0.5 mL of 1000 ppm Formate

1.0 mL of 1000 ppm Acetate

1.0 mL of 1000 ppm Propionate

1.0 mL of 1000 pnm Butyrate

to 100 mL with MHH-Q water.

Note: This working standard should be prepared weekly, since the

formate concentration decreases with time.

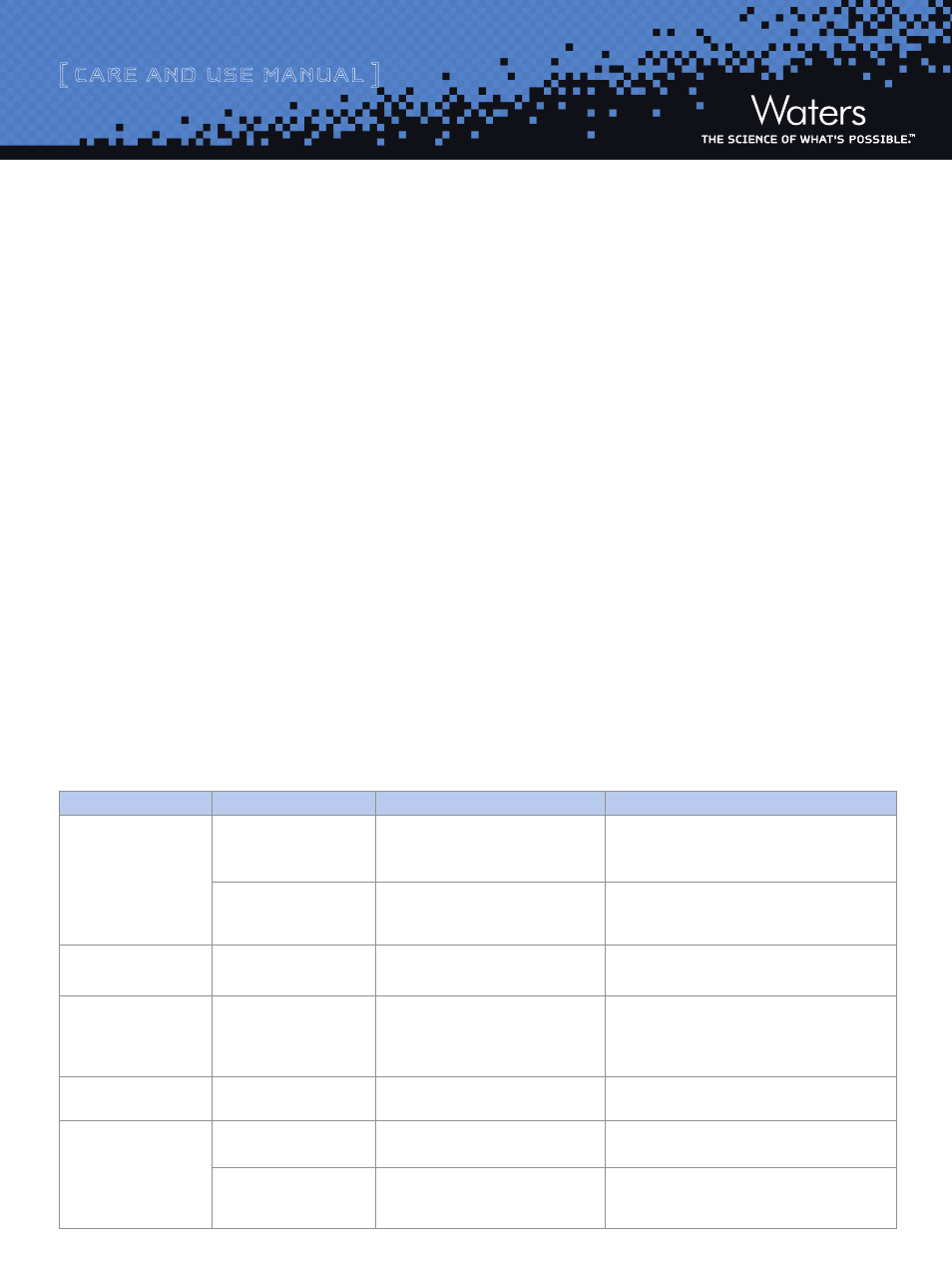

Symptom

Cause

Corrective Action

Prevention

Buildup in HPLC system

operating pressure

Inlet frit plugged with

particulates

Clean and regenerate column (see Sec-

tion V. b.). Check for injector and pump

seal shedding.

Always filter the eluent and sample prior to

use. Use an in-line filter between the pump and

injector.

Guard-Pak insert clogged

with particulates or

adsorbed materials

Replace the spent Guard-Pak insert.

Replace the

Guard-Pak inserts more frequently.

Fluctuating

backpressure

Gas in the eluent

Check degassing procedure, Displace

gas from the pump.

Always degas the eluent prior to use.

Spurious peaks

Weakly dissociated

inoganic anions can

sometimes coellute with

carboxylic acids

Analysze your sample for carbonate,

sulfite, or other anions using an IC-Pak

anionn column.

Modify sample preparation.

Variable elution times

Variation in flow rate or

eluent composition

Check flow rate being delivered. Check

eluent composition.

Always throughly mix eluents prior to use.

Band broadening or loss

of resolution

Guard-Pak insert fouled

Replace spend Guard-Pak insert.

Replace

Guard-Pak inserts more frequently.

Column fouled or old

Clean and regenerate the column

(see Section V. b.). If column does not

recover, use a new column.

Isolate the source of the contamination and use

a Guard-Pak insert to protect the column from

contaminants in the sample.

Table 2. Problems and Corrective Actions