Care and use manual, Ii. getting started, A. safety considerations – Waters Viridis SFC Columns User Manual

Page 2: B. column installation, C. column equilibration, D. initial column efficiency determination, Iii. column use, A. sample preparation

[ Care and Use ManUal ]

2

Viridis SFC Columns

II. GettInG stARteD

Each Viridis SFC column comes with a Certificate of Analysis and a

Performance Test Chromatogram. The Certificate of Analysis is specific

to each batch of packing material and includes the gel batch number,

analysis of unbonded particle and analysis of bonded particles. The

Performance Test Chromatogram is specific to each individual column

and contains the gel batch number, column serial number, USP plate

count, USP tailing factor, capacity factor, and chromatographic condi-

tions under normal-phase LC conditions. These data should be stored

for future reference.

a. Safety Considerations

An SFC column while being used is, by design, under pressure. The

major safety concern for even a small leak with just CO

2

is frostbite.

Pay attention to any frosting on the column or system connections.

This indicates a leak, usually with temperatures far below 0 °C. Any

small leak with solvent introduced could produce a situation where

the LEL (lower exposure limit) is reached.

b. Column Installation

Note: Scale the flow rate up or down accordingly based upon the i.d.,

length, particle size, and backpressure of the Viridis SFC column being

installed. See “Scaling Up/Down Isocratic Methods” for calculating

flow rates when changing column i.d. and/or length. See “Connecting

the Column to the SFC system” for a more detailed discussion on SFC

connections.

1. Make sure your co-solvent pump is primed and has an adequate

solvent/modifier supply before performing injections.

2. Connect both the inlet and outlet of the column to the SFC system.

3. If the column is still filled with a solvent, use a low flow rate and

back pressure setting (100 bar) to start pumping CO

2

and modifier

through the column.

4. If you see frosting on the column at the inlet or outlet, tighten the

compression screw on that side. If you see frosting on the column,

turn off the CO

2

and vent the system. Allow the column to depres-

surize fully before disconnecting the inlet or outlet to troubleshoot

the leaking issue.

c. Column Equilibration

Viridis SFC columns are shipped dry. Equilibrate the column with a mini-

mum of 10 column volumes of the mobile phase prior to use. (Refer to

Table 2 for a listing of empty column volumes.)

d. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it. Waters

recommends using a suitable solute mixture to analyze the column

upon receipt.

2. Determine the number of theoretical plates (N) and use this value

as a benchmark for periodic comparisons.

3. Repeat the test at predetermined intervals to track column

performance over time. Slight variations may be obtained on

two different SFC systems due to the quality of the connections,

operating environment, system electronics, reagent quality and

column condition.

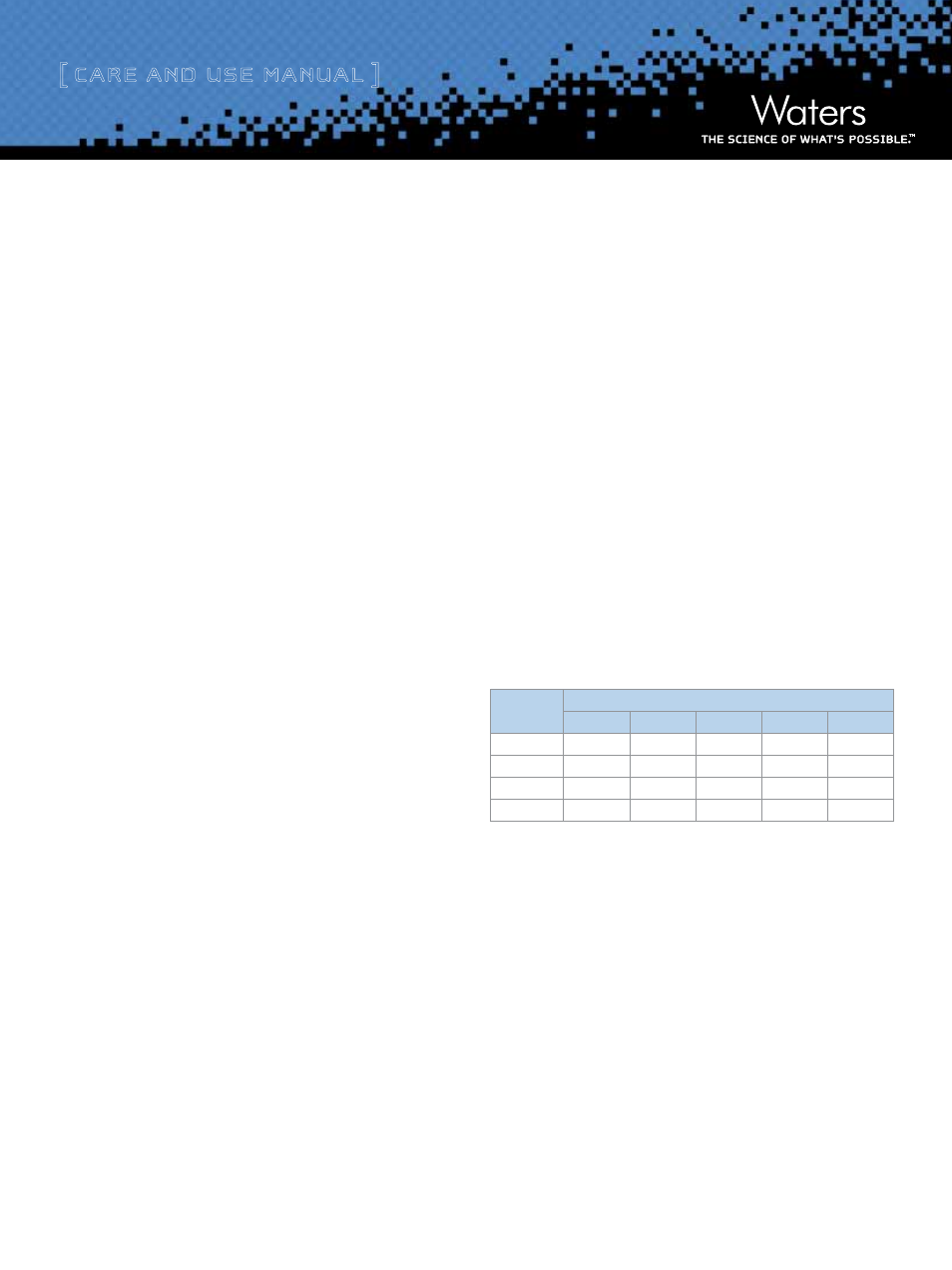

Table 2. Empty Column Volumes in mL (multiply by 10 for flush sol-

vent volumes)

Column

Dimension

Column Internal Diameter (mm)

4.6 mm

10 mm

19 mm

30 mm

50 mm

50 mm

0.8

4

14

35

98

100 mm

1.7

8

28

70

196

150 mm

2.5

12

42

106

294

250 mm

4

20

70

176

490

III. CoLUMn Use

To ensure the continued high performance of Viridis SFC columns,

follow these guidelines:

a. Sample Preparation

1. Sample impurities often contribute to column contamination.

Use Oasis

®

solid-phase extraction cartridges/columns or Sep-

Pak

®

cartridges of the appropriate chemistry to clean up the

sample before analysis. Link to www.waters.com/sampleprep.

2. Prepare the sample in the SFC mobile-phase modifier (typically,

methanol) for the best peak shape and sensitivity.