Care and use manual, Iii. scaling up/down isocratic methods, Iv. troubleshooting – Waters XSelect CSH130 C18 3.5 μm and 5 μm Columns User Manual

Page 5: Vi. column cleaning, regeneration and storage, A. cleaning and regeneration, B. storage

[ CARE AND USE MANUAL ]

XSelect CSH130 C

18

Columns

5

III. SCALING UP/DOWN ISOCRATIC METHODS

The following formulas will allow scale up or scale down, while maintaining

the same linear velocity, and provide new sample loading values:

If column i.d. and length are altered:

F

2

= F

1

(r

2

/r

1

)

2

Load

2

= Load

1

(r

2

/r

1

)

2

(L

2

/L

1

)

Injection volume

2

= Injection volume

1

(r

2

/r

1

)

2

(L

2

/L

1

)

Where:

r = Radius of the column

F = Flow rate

L = Length of column

1 = Original, or reference column

2 = New column

IV. TROUBLESHOOTING

Changes in retention time, resolution, or backpressure are often due to

column contamination. See the Column Cleaning, Regeneration and Storage

section of this Care and Use Manual. Information on column troubleshooting

problems may be found in HPLC Columns Theory, Technology and Practice,

U.D. Neue, (Wiley-VCH, 1997), the Waters HPLC Troubleshooting Guide

(Literature code # 720000181EN) or visit the Waters Corporation website

for information on seminars (www.waters.com).

VI. COLUMN CLEANING, REGENERATION AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shoulders on the peak, shifts in

retention, change in resolution or increasing backpressure may indicate

contamination of the column. Flushing with a neat organic solvent,

taking care not to precipitate buffers, is usually sufficient to remove the

contaminant. If the flushing procedure does not solve the problem, purge

the column using the following cleaning and regeneration procedures.

Use the cleaning routine that matches the properties of the samples and/or

what you believe is contaminating the column (see Table 3 ). Flush columns

with 20 column volumes each of HPLC-grade solvents (e.g., 80 mL total for

4.6 x 250 mm column) listed in Table 3. Increasing mobile phase temperature

to 35-55 ˚C increases cleaning efficiency. If the column performance is

poor after cleaning and regeneration, call your local Waters office for

additional support.

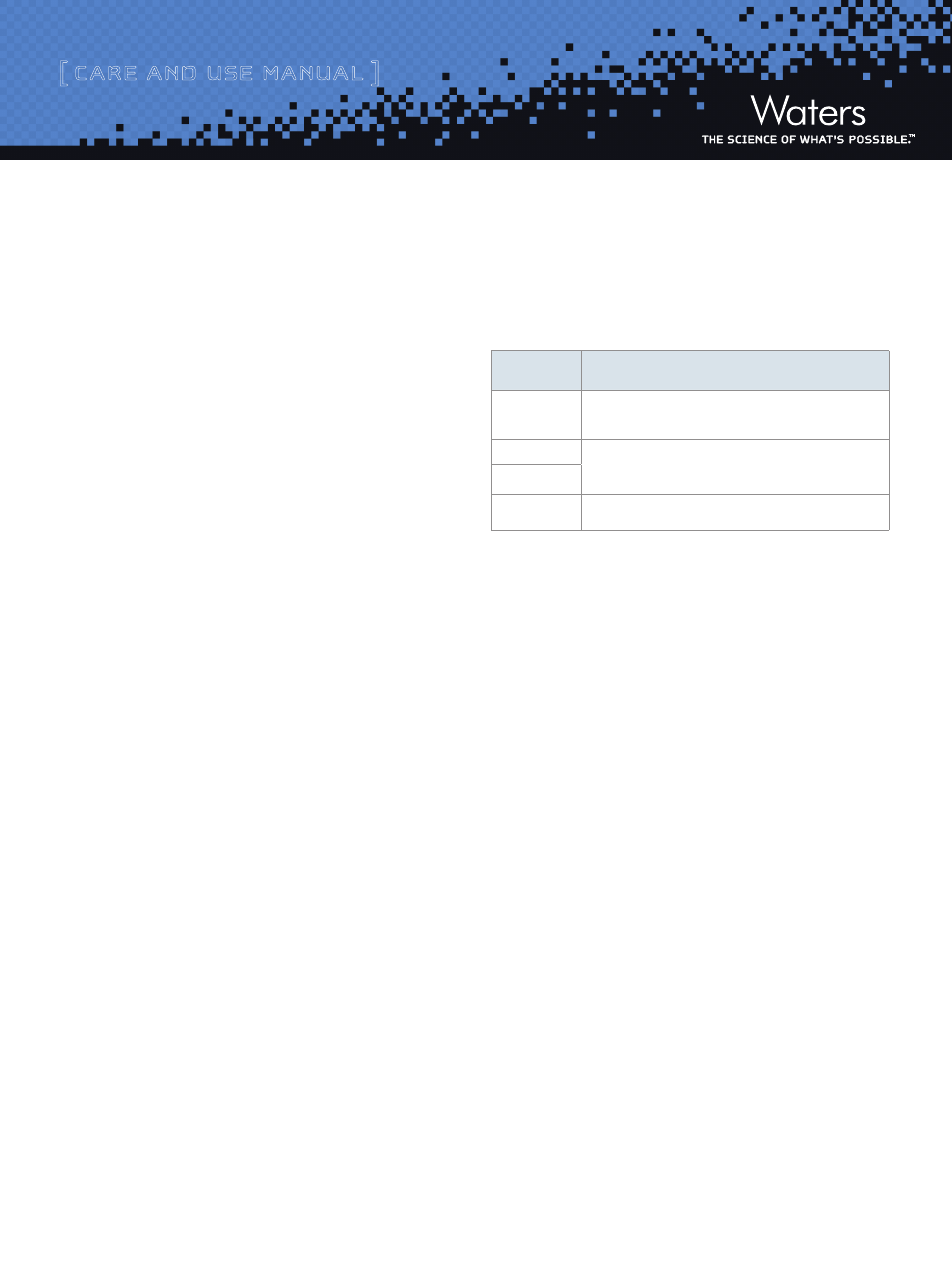

Table 3: Cleaning and Regeneration Sequence or Options

Polar Samples

Proteinaceous Samples

1. water

Option 1: Inject repeated 100 µL aliquots of dimethylsulfoxide

(DMSO) using a reduced flow rate delivering 50% Eluent A

and 50% Eluent B

2. methanol

Option 2: gradient of 10% to 90% B where:

A = 0.1% trifluoroacetic acid (TFA) in water

B = 0.1% trifluoroacetic acid (TFA) in acetonitrile (CH

3

CN)

3. isopropanol

Option 3: Flush column with 7M guanidine hydrochloride, or

7M urea

Note: To avoid potentially damaging precipitation within your column

(e.g., if your separation eluent contains phosphate buffer), be certain to

flush column with 5 to 10 column volumes of water BEFORE using suggested

organic eluent column wash procedures.

b. Storage

For periods longer than four days at room temperature, store the column

in 100% acetonitrile. Immediately after use with elevated temperatures

and/or at pH extremes, store in 100% acetonitrile for the best column

lifetime. Do not store columns in highly aqueous (<20% organic) mobile

phases, as this may promote bacterial growth. If the mobile phase con-

tained a buffer salt, flush the column with 10 column volumes of HPLC

grade water (see Table 1 for common column volumes) and replace with

100% acetonitrile for storage. Failure to perform this intermediate step

could result in precipitation of the buffer salt in the column or system

when 100% acetonitrile is introduced. Completely seal column to avoid

evaporation and drying out of the bed.

Note: If a column has been run with a mobile phase that contains formate

(e.g., ammonium formate, formic acid, etc.) and is then flushed with 100%

acetonitrile, slightly longer equilibration times may be necessary when the

column is re-installed and run again with a formate-containing mobile phase.