Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 78

Form # 46290

Issue 09/05

76

MAINTENANCE/SERVICE

HAY CONDITIONER

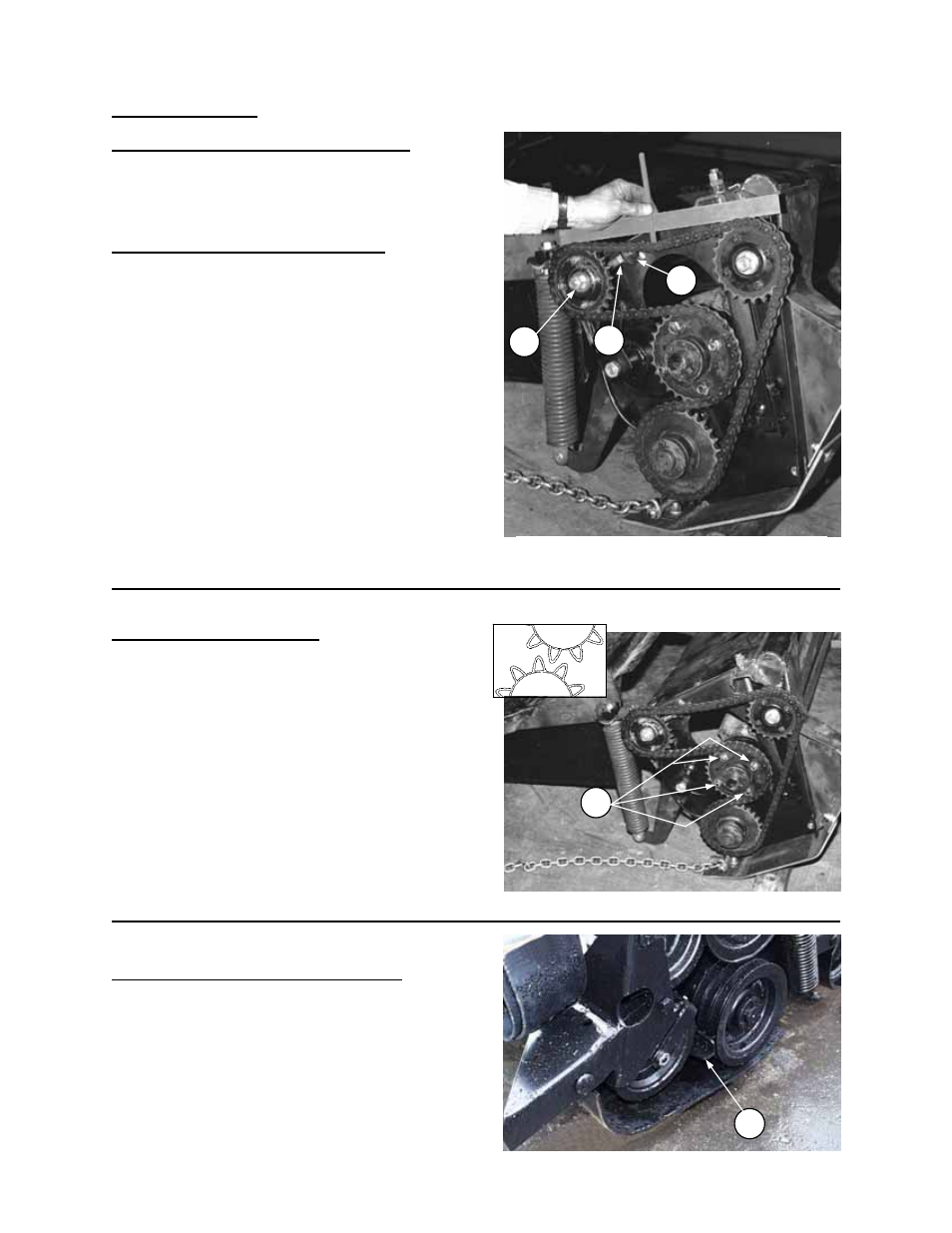

Hay Conditioner Drive Chain Lubrication

Lubricate chain daily with lightweight oil (SAE 30).

Hay Conditioner Drive Chain Tension

Check hay conditioner drive chain tension after the

first 2 hours operation and every 100 hours

thereafter.

To check chain tension: Place a straightedge

across idler sprockets as shown. Light pressure at

mid-span should produce 5/8 in. (15 mm)

deflection.

If adjustment is required:

1. Loosen nut (A).

2. Back off nut (D) and turn nut (E) to push

sprocket rearward to increase tension to above

specification. Do not over-tighten.

3. Tighten nuts (A) and (D) to secure the position.

Hay Conditioner Roll Timing

Rolls must be timed to prevent contact between

bars. Bars of one roll must be approximately

centered between bars of the other roll as

illustrated.

When installing roll drive chain:

1. Rotate rolls to approximately correct timing.

2. Install chain.

3. Set roll timing as follows:

• Loosen four nuts (A) at upper roll sprocket.

• Rotate sprocket to achieve best roll timing.

• Tighten nuts (A) to secure the position.

Hay Conditioner Pulley Clean-Out Bolts

When installing hay conditioner drive belt, ensure

mounting bracket (B) for clean-out bolts on lower

roll driven pulley is not interfering with belt travel.

Also, ensure clean-out bolts are centered in pulley

grooves. Mounting bracket can be adjusted

laterally to properly position bolts.

A

D

E

CONDITIONER DRIVE CHAIN TENSION

B

A

ROLL TIMING ADJUSTMENT