Operation – MacDon 742 HAY CONDITIONER User Manual

Page 28

Form # 46290

Issue 09/05

26

OPERATION

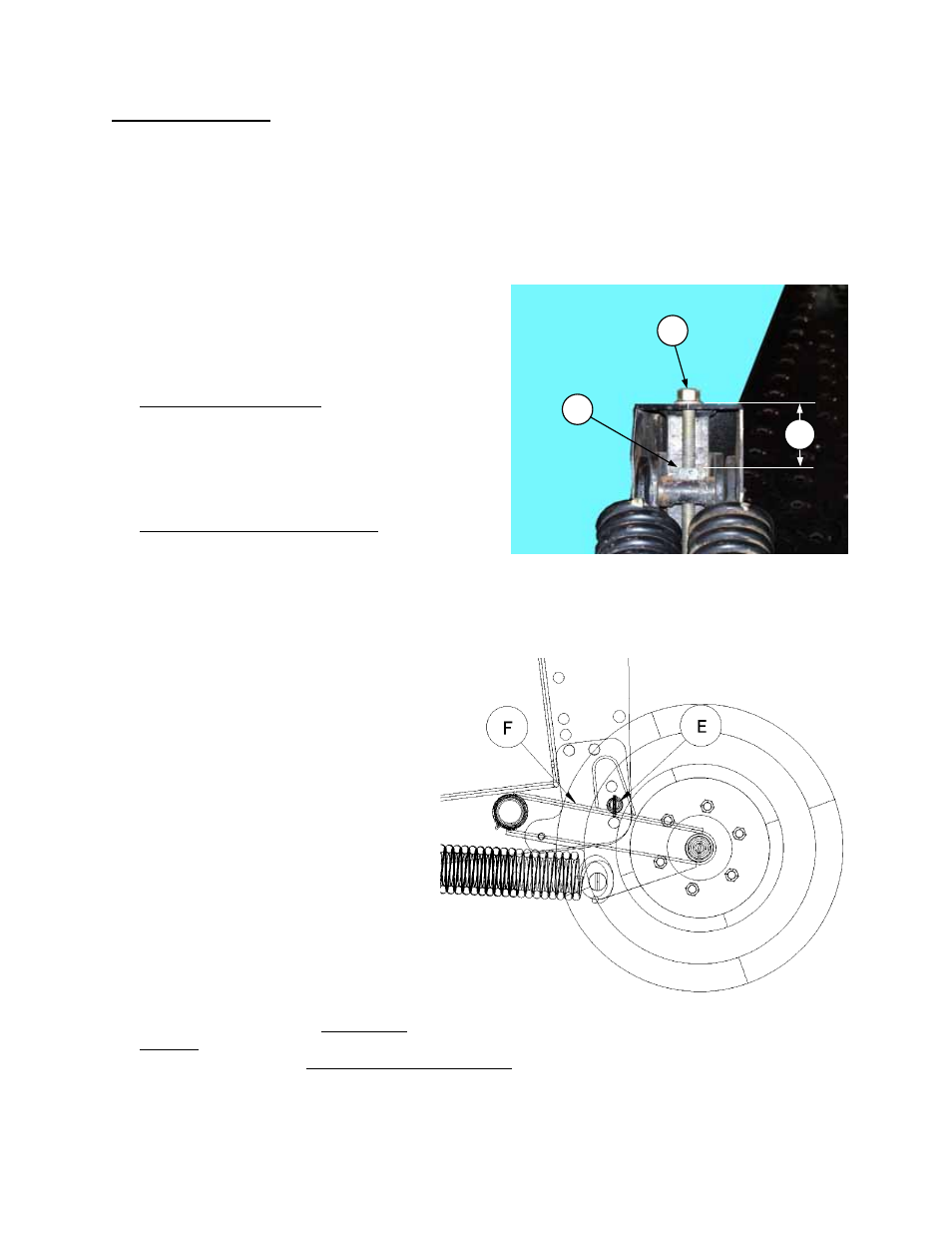

HEADER FLOTATION

IMPORTANT: To avoid frequent breakage of sickle components, scooping soil, or soil build-up at cutterbar in

wet conditions, header float should be set as light as possible without causing excessive bouncing.

Under normal conditions with cutterbar lowered (just off the ground), adjust float spring tension so 50 to 70 lbs.

of force (220 to 310 N) is required to lift cutterbar off ground at each end.

See "Header Flotation" in Windrower or Combine Adapter Operator's Manual for adjustment details.

NOTE: 30’ & 36’ Headers with gauge wheels use the

springs in the gauge wheel package to assist in

header floatation. As such, the windrower float

adjustment is different for these headers. Proceed as

follows:

1. 30’ Single Sickle Header: With gauge wheels

installed with dual springs on left hand side and

single spring on right hand side, adjust float spring

drawbolt dimension (A) on tractor to approximately

5.1 in. (130 mm) on the left side and 3.7 in. (95

mm) on the right side.

30’ Double Sickle & 36’ Header: With gauge

wheels installed with dual springs on both sides,

adjust float spring drawbolt dimension (A) on

tractor to approximately 3.5 in. (90 mm) on the left

side and 5 in. (125 mm) on the right side.

NOTE: For 36’ headers, one of the left-hand dual

springs on the tractor must have auxiliary inner

spring installed. For auxiliary inner spring kit order

B 2773.

NOTE: For 36’ Double Sickle headers,

four kits B 2773 are required.

2. Set gauge wheels to medium stubble

height position (E).

3. Set center link to approximately 21.5 in.

(545 mm) pin to pin.

4. Adjust tractor float spring drawbolts

such that gauge wheel arm (F) contacts

pin (E) when the header is lowered. If

header floats away from the pin, reduce

float [increase dimension (A)]. If arm (F)

contacts pin but float is heavy, increase

float [decrease dimension (A)].

5. To adjust float:

• Raise header fully, shut off engine and

remove key.

• Loosen nut (C).

• Turn spring drawbolt (B) clockwise to

increase float (which makes header lighter when lowered to ground).

• Turn spring drawbolt (B) counter-clockwise to decrease float (which makes header heavier when lowered

to ground).

• Tighten nut (C) to lock the position.

• Lower header fully and check float at both ends of cutterbar. Force required to lift cutterbar should be

approximately the same at both ends.

GAUGE WHEEL

FLOAT ADJUSTMENT - WINDROWER

B

A

C