Operation – MacDon 742 HAY CONDITIONER User Manual

Page 33

Form # 46290

Issue 09/05

31

OPERATION

END DELIVERY: 21', 25', 30' & 36' MANUAL SHIFT HEADERS: The left or right deck of the 21' to 36' manual shift

header can be moved to close off the center opening and deliver crop to either end of the header. This provides the

capability of windrowing with a combine or non-windrower tractor as the power unit.

NOTE: For 36’ Header, a kit is available to split the R/H deck to deliver crop next to the combine tire. See Options

and Attachments section.

To shift deck (Manual Shift Headers): NOTE: Steps 3,

4, 5, 10, 12 and 14 apply to Combine Headers only.

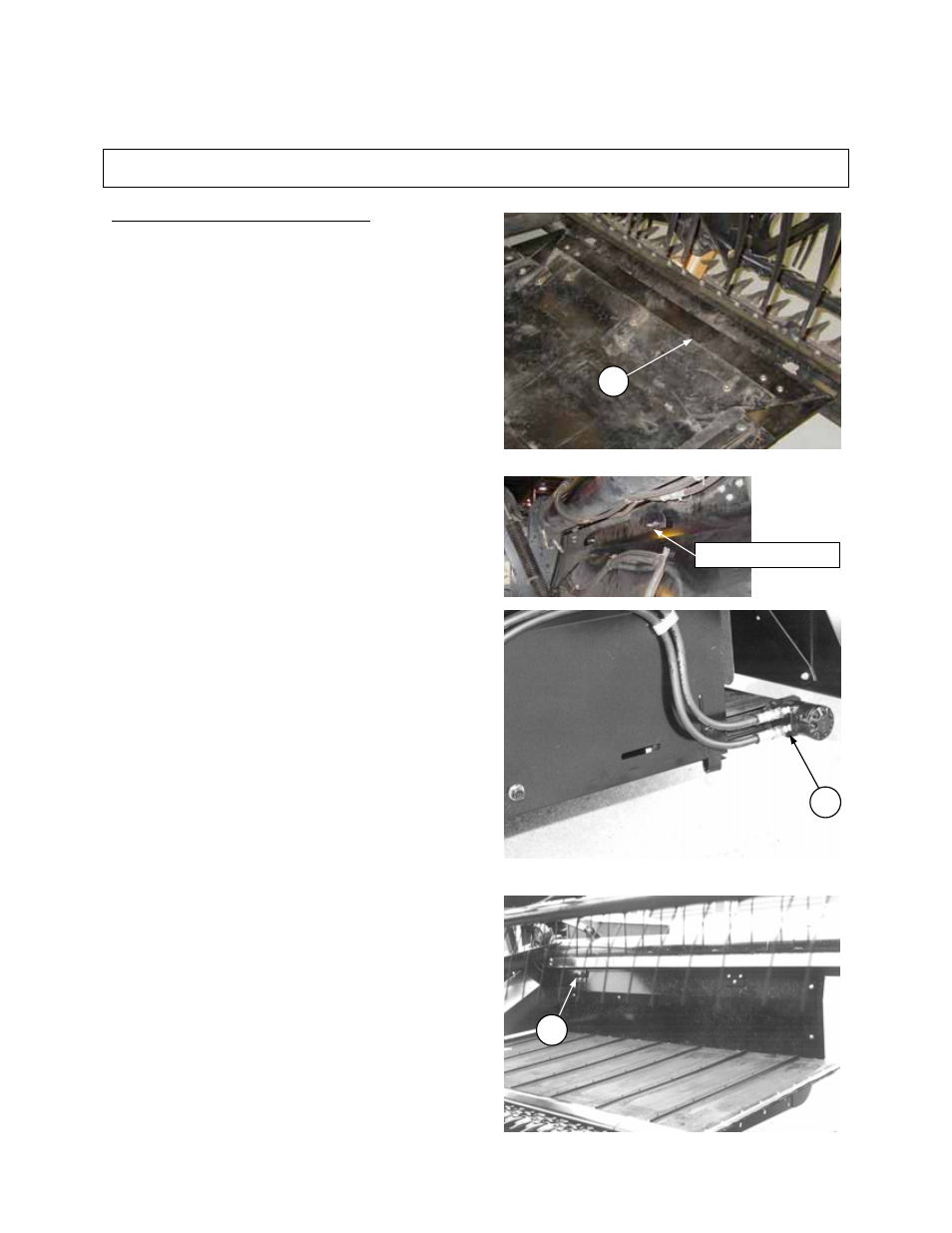

1. Install bar (C) onto lugs across center opening at

cutterbar. Note that end tabs bend down and holes in

bar are towards rear of header. This bar prevents

draper damage when end delivering. (Bar is stored on

deck backsheet.)

2. Reverse draper travel on the deck being moved by

disconnecting hydraulic hoses at draper motor (A) and

install in opposite ports.

3. Stop hydraulic flow to the adapter feed draper and

drum. See Combine Adapter Operator’s Manual for

procedure (872 reference: “Draper Speed Control” /

873 reference: “Windrowing with the Combine”).

4. Lower the header to the ground and continue until

adapter lowers to clear deck shift lug.

5. Lengthen center link between header and adapter to

steepest header angle to clear hose clamps on header

back sheet

6. Loosen nut at clamp (B) and slide deck across center

opening until there is approximately 2 inches (50 mm)

clearance between the rollers of the two decks.

IMPORTANT: This clearance is required to prevent

contact between draper connectors or slats as they

pass between decks.

For Combine applications only:

NOTE: If there is interference between deck backsheet

and combine adapter retracting tine drum, move drum

back to provide clearance. See “Drum Fore-Aft

Adjustment” in Adapter Operator’s Manual.

7. Tighten nut at clamp (B).

8. Readjust center link to achieve desired header

operating angle.

9. Move backsheet extensions to close off center opening

(see step 9, previous page).

10. With header and combine feed chain drum floated up,

check clearances: There should be 1 to 2 inches (25 to

50 mm) clearance between adapter drum and combine

feed chain drum, while still providing adequate

clearance to header backsheet. If repositioning adapter

drum does not provide enough clearance both fore and

aft, remove one row of tines from drum (2 or 3 tines,

depending on drum size).

11. Adjust header flotation to compensate for the shift in

weight. See "Header Flotation" in Windrower or

Combine Adapter Operator's Manual.

12. For rotary combines with narrow feeder opening,

increase delivery opening width to be suitable for

windrowing. See "Delivery Opening Width", beginning

on page 28.

13. To maximize clearance between windrow and standing

crop, order “End Delivery Forming Rods”. See Options

and Attachments section.

14. If header drapers catch on feed draper deck or

deflectors, adjust feed pan spacer plate. See “Feed

Pan Clearance Adjustment” in Adapter Op. Manual.

A

REVERSE HOSES AT DRAPER MOTOR

B

LOOSEN NUT AND SLIDE DECK

C

INSTALL GUIDE BAR FOR END DELIVERY

GUIDE BAR STORAGE