Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 73

Form # 46290

Issue 09/05

71

MAINTENANCE/SERVICE

Drive Roller Maintenance

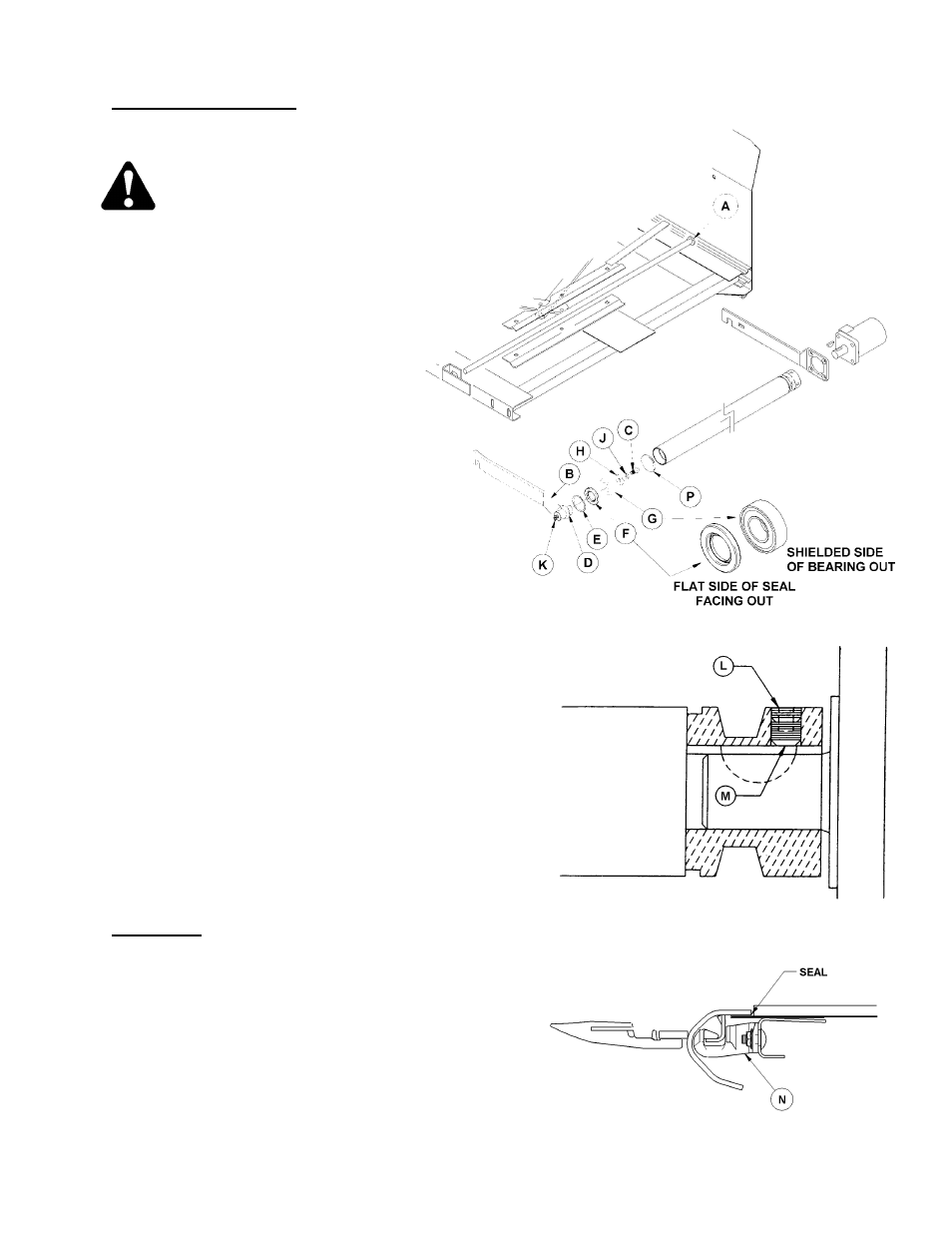

To replace drive roller bearings:

1. Raise header and reel.

CAUTION: Engage header lift cylinder stops

and reel props before working under header

or reel.

2. On 21’ to 36’ headers, position deck so drive

roller is easily accessible.

3. Loosen and uncouple draper.

4. If drive roller is at end of header, remove drive

roller assembly by sliding spring rod (A)

through hole in backsheet and pulling roller

out. (Loosen hose clamps to allow slack in

hydraulic hoses.)

If drive roller is at center opening,

remove the bolt holding rear bar in deck

and remove roller assembly.

5. Remove bearing assembly from roller

tube by tapping on arm at (B) while

holding roller. Disassemble by removing

bolt (C). NOTE: Retaining disk (P)

remains inside roller tube.

6. Clean inside of roller tube and stub shaft (D). Check tube

and stub shaft for wear or damage. Replace if necessary.

7. Place retaining ring (E) onto stub shaft (D) and hang it

loosely over stub shaft mounting face.

IMPORTANT: Retaining ring must be in position on stub

shaft before installing bearing into tube.

8. Sub-assemble seal (F), bearing (G) and washer (H) onto

stub shaft and secure with lockwasher (J) and bolt (C).

IMPORTANT: Install seal (F) with flat face (with writing) out,

and install bearing (G) with shielded side out.

9. Remove grease fitting (K) and press on end of stub shaft to

install bearing sub-assembly into roller tube. Press in until

retaining ring (E) can be installed in groove inside tube. To

prevent damage to bearing, do not press the assembly

deeper than necessary.

10. Reinstall fitting (K) into stub shaft and grease until grease

appears past seal.

11. Reassemble drive roller into deck, re-couple and tighten

draper.

NOTE: At drive roller to motor connection, there is a short

"through-bore" setscrew (L) on top of setscrew (M). When

removing, be sure to engage Allan wrench only far enough to

remove setscrew (L) first, then setscrew (M).

Deck Height

To prevent material from entering drapers and cutterbar,

maintain deck height so that draper runs just below cutterbar

with maximum 1/32” (1 mm) gap, or with draper deflected

down slightly [up to 1/16” (1.5 mm)] to create a seal.

Adjust as follows:

1. Loosen tension on drapers.

2. Lift draper up at front edge and loosen two nuts on deck

support (N), two or three per deck, depending on header

size.

3. Tap deck up or down relative to supports to achieve setting

recommended above.

4. Tighten deck support hardware and tension drapers.

DRIVE ROLLER TO MOTOR CONNECTION

DECK HEIGHT ADJUSTMENT