Operation – MacDon 742 HAY CONDITIONER User Manual

Page 46

Form # 46290

Issue 09/05

44

OPERATION

HAY CONDITIONER FORMING SHIELDS

CAUTION: Keep forming shields installed at all times conditioner is in use. Do not allow

anyone to stand behind the machine while operating. Stones or other foreign objects may be

ejected from the conditioner with force.

The side and rear deflectors are adjustable to shape the windrow to your preference.

In deciding on windrow width, the following factors should be considered:

• weather conditions (rain, sun, humidity, wind)

• type and yield of crop

• drying time available

• method of processing (bales, silage, "green-feed")

A wider windrow will generally dry faster and more evenly, resulting in less protein loss. Fast drying is

especially important in areas where the weather allows only a few days to cut and bale. See "Haying Tips" in

this section for more information.

Where weather conditions permit or when drying is not critical, for example, when cutting for silage or "green-

feed", a narrower windrow may be preferred for ease of pick-up.

Windrow Width

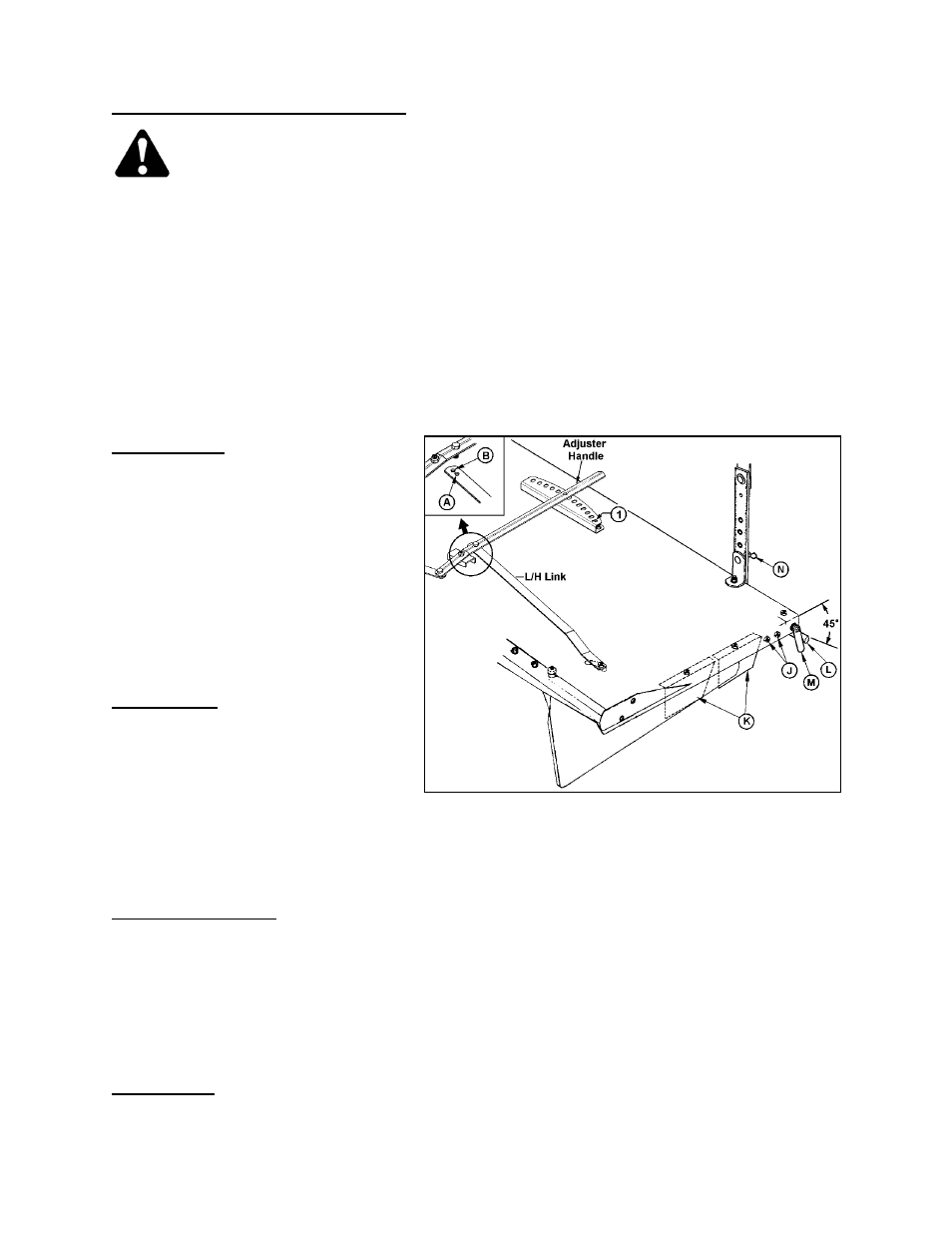

Position the adjuster handle as required to

move the side deflectors to the desired

width.

NOTE: With hardware installed in hole (A)

in L/H link as shown, deflectors will move

symmetrically about the center of the

conditioner rolls. For the most evenly

formed windrows, use position (A) for

windrows up to 60 inches wide. Use hole

(B) only when windrows over 60 inches are

required, as this allows the left deflector to

open to a wider position than the right

deflector. Maximum width is with hardware

in hole (B) and handle in Position (1).

Rear Deflector

The rear deflector (L) slows the crop exiting

the conditioner rolls, directs the flow

downward, and "fluffs" the material.

To start, adjust rear deflector to

approximately the mid-range position (45

°).

Optimum position for best windrow

uniformity must be determined for each crop

condition.

To adjust rear deflector, loosen adjuster handles (M), one per side, position deflector and tighten adjuster

handles (M). For even windrow formation, be sure deflector is not twisted.

Forming Shield Height

Depending on the amount of crop material, the rear of the forming shield assembly can be raised or lowered to

properly deflect the crop. As a starting point, set forming shield height at the 3

rd

hole from the bottom of the

rubber straps. For lighter crops, lower forming shield as required to form the most uniform windrows. Too high

a setting does not allow the deflectors to shape the windrow, while too low a setting will cause uneven and

poorly formed windrows.

To adjust forming shield rear height, remove hairpin (N), both sides, and raise or lower shields to desired

height.

Deflector Fins

Four fins provided standard are stored at (K) on the top L/H side of the top cover. Additional fin hardware

required is stored at (J). Continued next page.

HAY CONDITIONER FORMING SHIELDS