Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 66

Form # 46290

Issue 09/05

64

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

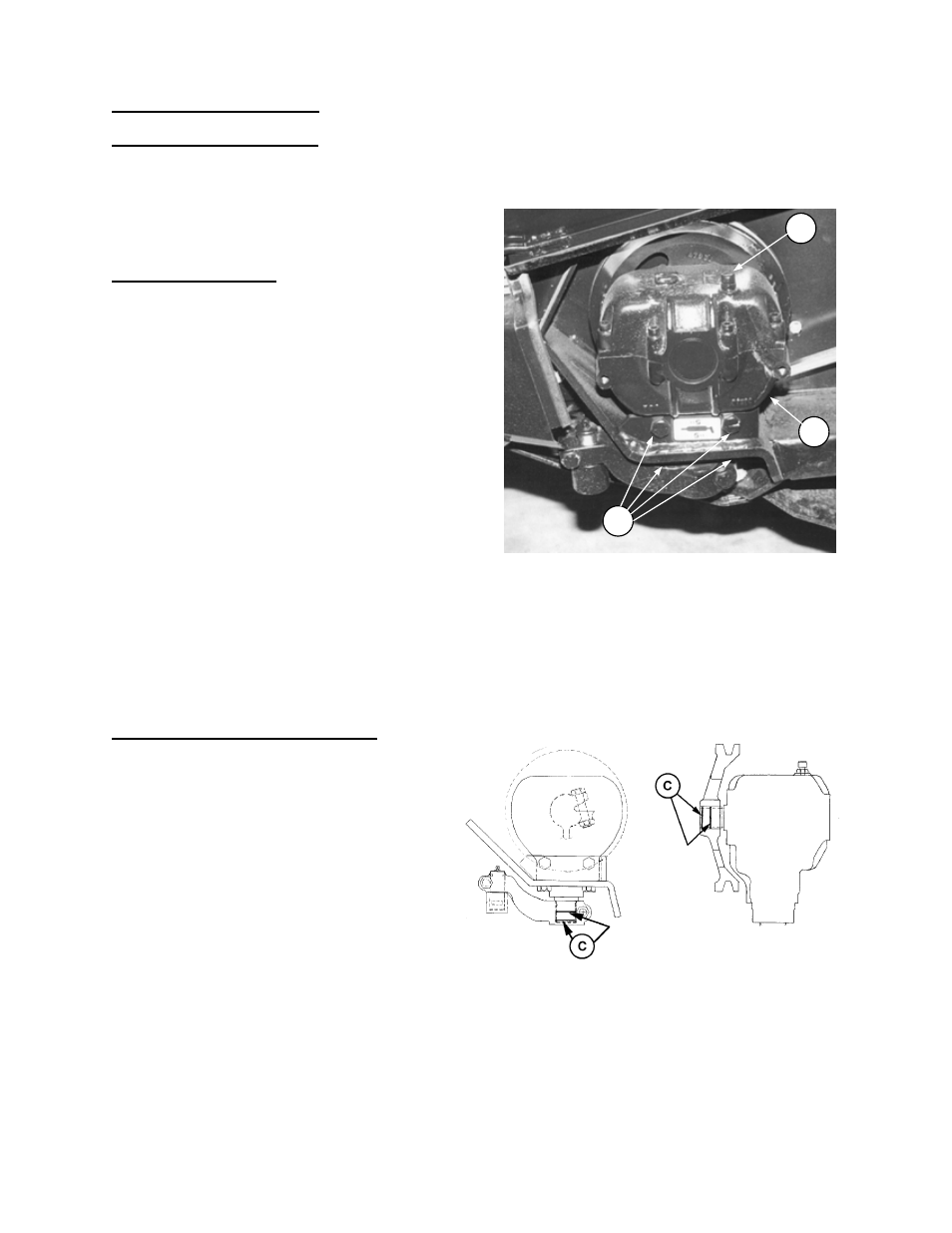

Wobble Box Mounting Bolts

Tighten the four wobble box mounting bolts (A)

after the first 10 hours operation and every 100

hours thereafter. Torque to 200 ft.lbs. (270 N·m),

starting with the side mounting bolts.

Wobble Box Lubricant

Check wobble box lubricant level before first

operation and every 100 hours thereafter.

To check:

1. Raise header to a point where the wobble box

base is approximately level.

2. Remove breather/dipstick (B). Oil level must be

between end of dipstick and bottom hole (or

groove) in dipstick.

3. Add as required.

Change wobble box lubricant after first 50 hours

operation and every 1000 hours or 3 years

thereafter.

To drain wobble box, raise header fully and

engage header lift cylinder stops. Remove

breather/dipstick (B) and drain plug (D).

Use SAE 85W-140 gear lubricant (API Service

Classification GL-5). Capacity of box is 2.2 litres

(2.3 U.S. quarts)

Wobble Box Assembly/Disassembly

When reinstalling drive arm or pulley:

1. Remove any rust or paint from inner

spline. For replacement parts, remove

oil/grease with degreasing agent.

2. Before assembly, apply Loctite® #243

adhesive (or equivalent) to spline.

Apply in two bands (C) as shown, with

one band at end of spline and one

band approximately mid-way.

B

A

WOBBLE BOX

D