Operation – MacDon 742 HAY CONDITIONER User Manual

Page 43

Form # 46290

Issue 09/05

41

OPERATION

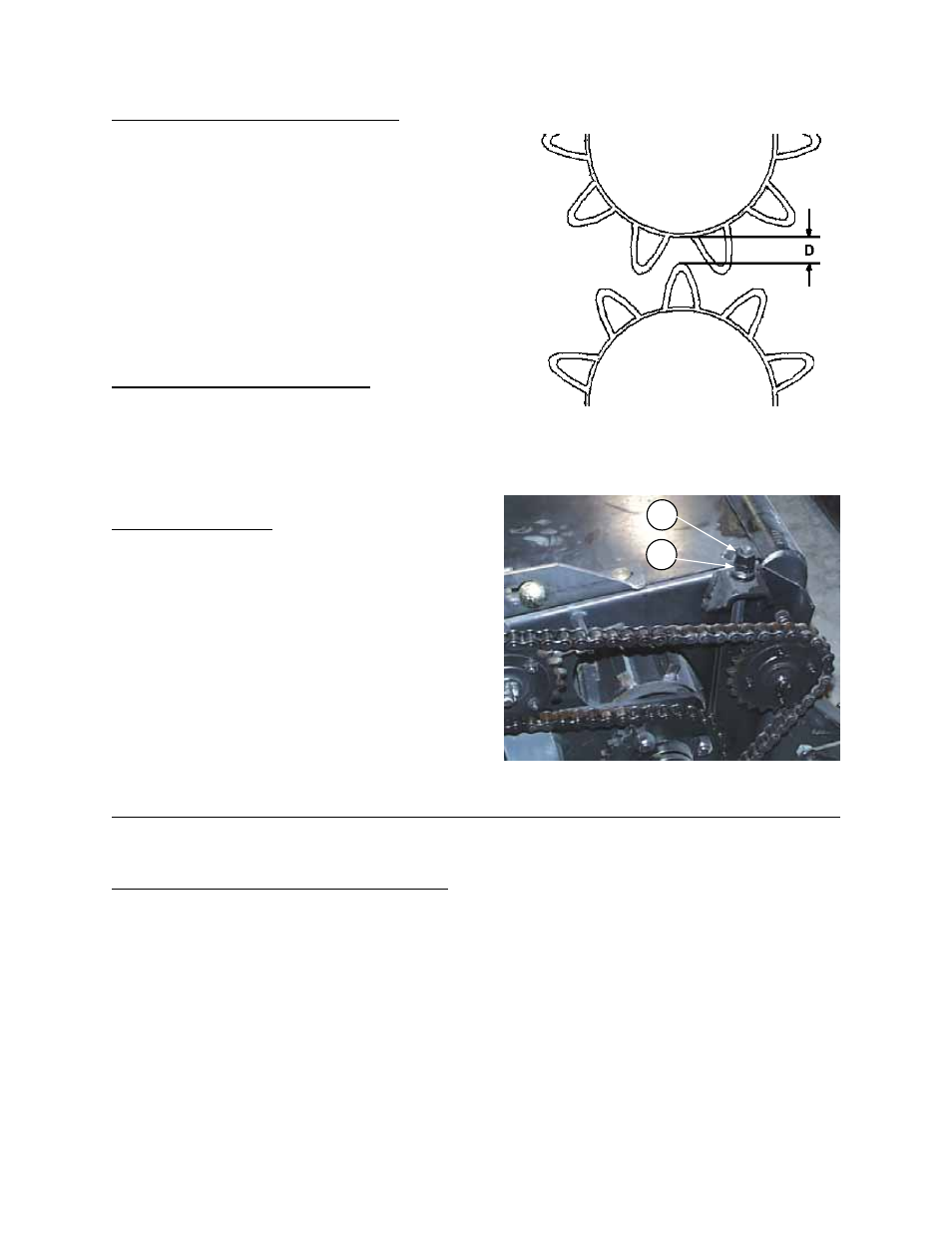

HAY CONDITIONER ROLL INTERMESH

The intermeshing steel rolls of the hay conditioner

crimp the plant stems in several places, allowing

moisture release and quicker drying.

The degree to which the stems are conditioned

(crimped) depends on the amount of roll intermesh

and roll spring tension (see below).

Correct conditioning of alfalfa, clover and other

legumes is usually indicated when 90% of the

stems show crimping but no more than 5% of the

leaves are damaged. To achieve this, roll

intermesh is factory set so that dimension (D) is

3/4 inch (20 mm) for normal operation.

In thick stemmed cane-type crops, heavy oats,

winter forage, etc., slightly less intermesh may be

desirable (D = approximately 1 inch); however too

little intermesh will cause feeding problems.

To adjust roll intermesh:

IMPORTANT: Make equal adjustments on both

sides of conditioner to achieve consistent

intermesh across the rolls.

1. Loosen nut (E).

2. Turn nut (F) clockwise to decrease intermesh,

or counter-clockwise to increase intermesh.

NOTE: Nut (F) is welded to adjuster tube, so

complete assembly will turn.

3. A 7/8-inch nut can be used to check intermesh.

(A 7/8-inch nut is 3/4 inch (20 mm) high.)

4. When intermesh is correct, tighten nut (E) while

holding nut (F) with another wrench to lock the

position securely.

HAY CONDITIONER ROLL TENSION SPRINGS

The conditioner roll intermesh is maintained by two

tension springs to provide adequate pressure for

correct conditioning of the crop. These springs

also allow the rolls to open to allow passage of

small solid objects without damage to the rolls.

The roll tension has been factory set and is not

adjustable.

ROLL INTERMESH ADJUSTMENT

E

F

ROLL INTERMESH

(Maintain ¾" (20 mm) bar-to-roll gap)