Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 69

Form # 46290

Issue 09/05

67

SICKLE TIMING

DOUBLE SICKLE IDLER ALIGNMENT

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

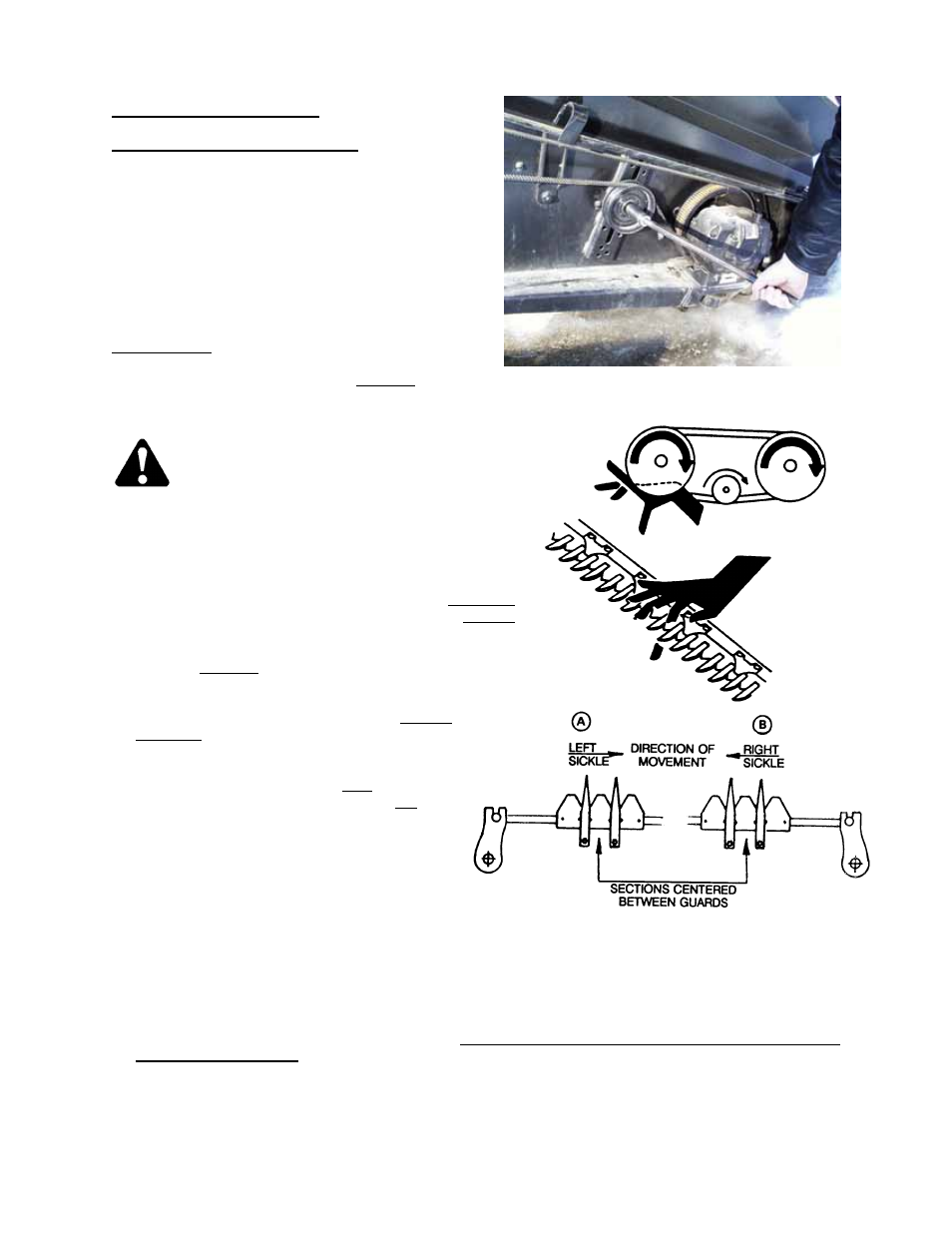

Double Sickle Drive Belt Tracking

To correct double sickle timing belts from riding hard

against either flange of idler pulley:

1. Use a 15/16 deep socket and pry bar on nut

securing idler pulley as shown.

2. If belt is riding against outside flange, push bar

forward to change pulley alignment.

3. If belt is riding against inside flange, push bar

rearward.

Sickle Timing (Double Sickle Headers)

To prevent excessive vibration, the left and right sickles

must be accurately timed to move in opposite directions.

Timing is achieved by rotating the wobble box pulley as

required when installing the wobble box drive belts.

CAUTION: Before timing sickles remove keys

from power unit. Be sure cutterbar is clear

before turning sickle drive.

To time the sickles:

1. Install the left hand wobble box drive belt and tension as

described (previous page). Check that the belt is properly

seated in the grooves on both driver and driven pulleys.

2. Rotate the left hand wobble box driven pulley clockwise

until the left hand sickle (A) is at the center of the inboard

stroke (moving towards the center of the header).

NOTE: Center stroke is when the sickle sections are

centered between the guard points as shown.

3. Remove the right hand drive belt from the

wobble box pulley and rotate the pulley counter

clockwise until the right hand sickle (B) is also

at the center of the inboard stroke.

IMPORTANT: It is critical that sickles are

centered at guard points while both are moving

towards the center of the header, not one

moving inboard and one moving outboard.

4. Install the right hand wobble box drive belt and

tension as described (previous page).

NOTE: To maintain timing, wobble box driver

and driven pulleys must not rotate as the belt is

tightened.

Tighten all hardware and check that the belt is

properly seated in the grooves on both driver and

driven pulleys.

5. Check for correct sickle timing by rotating the rear cross-shaft slowly. Observe sickles where they over-lap

at the center of the header.

IMPORTANT: At the start of each stroke, sickles must move in opposite directions and must begin to move

at exactly the same time. If timing is slightly off, loosen right hand belt just enough to allow skipping the belt

one or more teeth as required: If R/H sickle "leads" L/H, rotate right hand driven pulley clockwise. If R/H

sickle "lags" L/H, rotate pulley counter-clockwise. Tighten right hand belt.