Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 71

Form # 46290

Issue 09/05

69

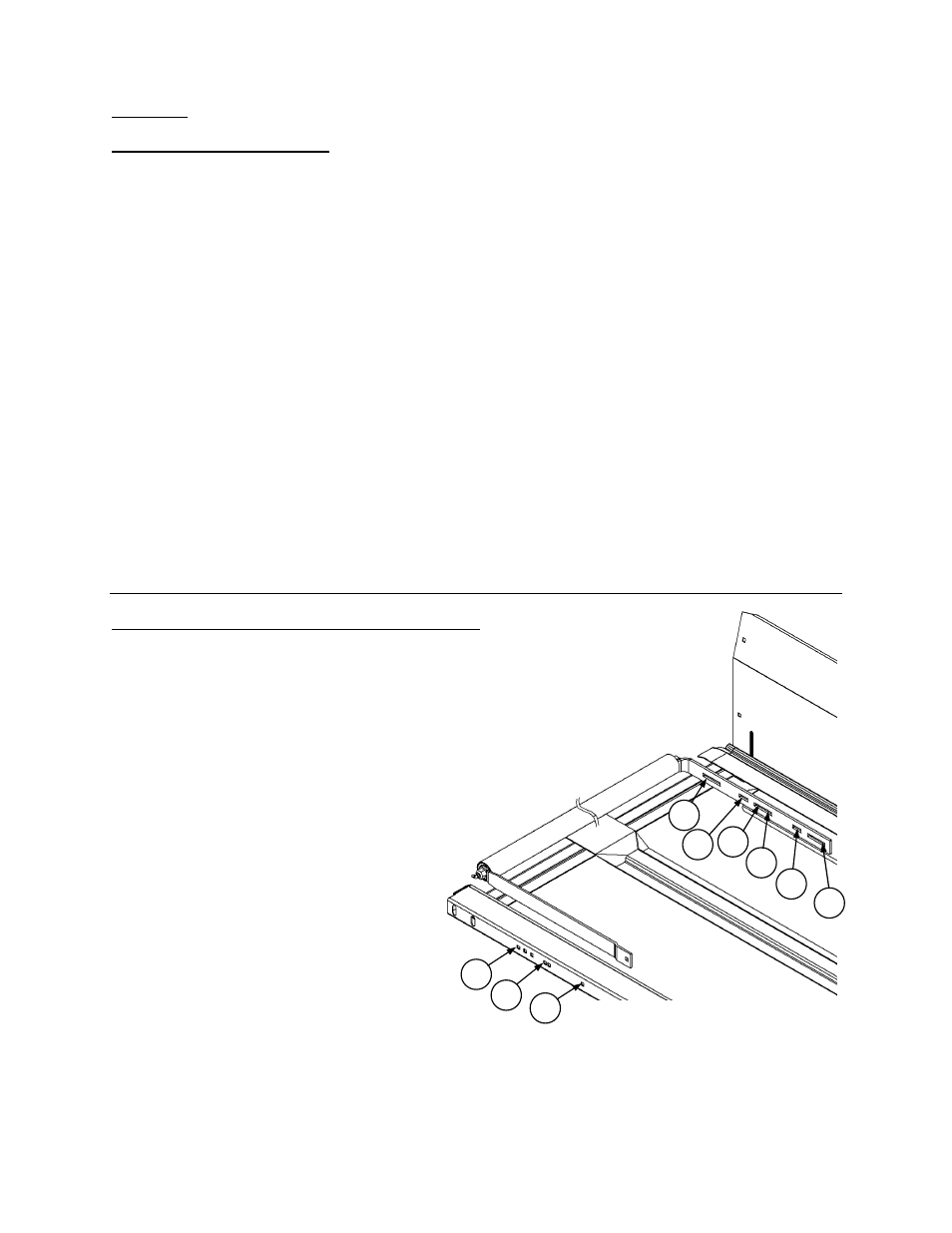

POSITIONING IDLER ROLLER BARS

A

A

C

B

C

B

B

C

A

MAINTENANCE/SERVICE

DRAPERS (continued)

Draper Drive Motor Locations

The load carrying capacity of the deck is affected by:

• Position of the drive motors (inboard or outboard).

• Spring-loaded

tensioner.

• Direction of draper travel.

The draper drive motors may be moved to either the inboard (at delivery opening) or outboard (at end sheets)

position.

If draper slippage is occurring at the drive roller due to excessive loads on top of the draper, it may be

beneficial to move the motors inboard.

NOTES:

1. If both drapers are stalling at the same time, a hydraulic system overload is indicated. In this situation,

moving drive motors will not improve performance.

2. Drapers may stall if sickle is not cutting well, or if crop is not dividing properly. If either of these problems is

evident, try to correct it before moving motors.

Use the following guidelines to determine where drive motors should be for a particular application:

1. If the header is used on a combine or with a hay conditioner, motors must be in outboard positions for

clearance reasons.

2. If the header is primarily used for end delivering, motors are best located in the outboard positions.

3. If the header is primarily used to windrow heavy crops in center delivery with no hay conditioner, motors

should be inboard.

For instruction on moving draper motors, see “Assembly” section at the back of this book.

Idler Roller Positioning - 21', 25', 30' & 36' Headers

Position the idler roller bars at center opening as follows:

• wider opening sizes: hardware at (A) - used for windrower applications

and John Deere*, New Holland TX and Lexion 460, 465, 480 & 485

Combines.

• mid-range opening sizes: hardware at (C) - used for Lexion 450, 470 &

475 Combines

• narrower opening sizes: hardware at (B) - used for Case, New Holland TR

and Gleaner Combines.

NOTE: To achieve narrowest opening sizes, move complete

deck assemblies inboard. Ensure outboard ends of draper

are still at least partially covered by wide crop deflectors.

The decks are factory assembled in the "wide

opening" position.

To change idler roller bars to mid or narrow

position:

1. Loosen draper completely, and remove

connector slats.

2. Remove hardware at (A).

3. Pull idler roller out of deck far enough to

install bolts at holes (B) or (C) as required.

4. Tighten bolt at front of deck only.

5. For proper draper tracking, check roller

alignment as described on next page.

6. Tighten two bolts at rear of deck.

7. Reinstall drapers.

8. Repeat at other deck.

* NOTE: For John Deere CTS Combines with

dust shields in rice applications, adapter may

have been converted to a mid-size deck. In this

case, use position C instead of A.