Unloading & assembly – MacDon 742 HAY CONDITIONER User Manual

Page 104

Form # 46290

Issue 09/05

102

UNLOADING & ASSEMBLY

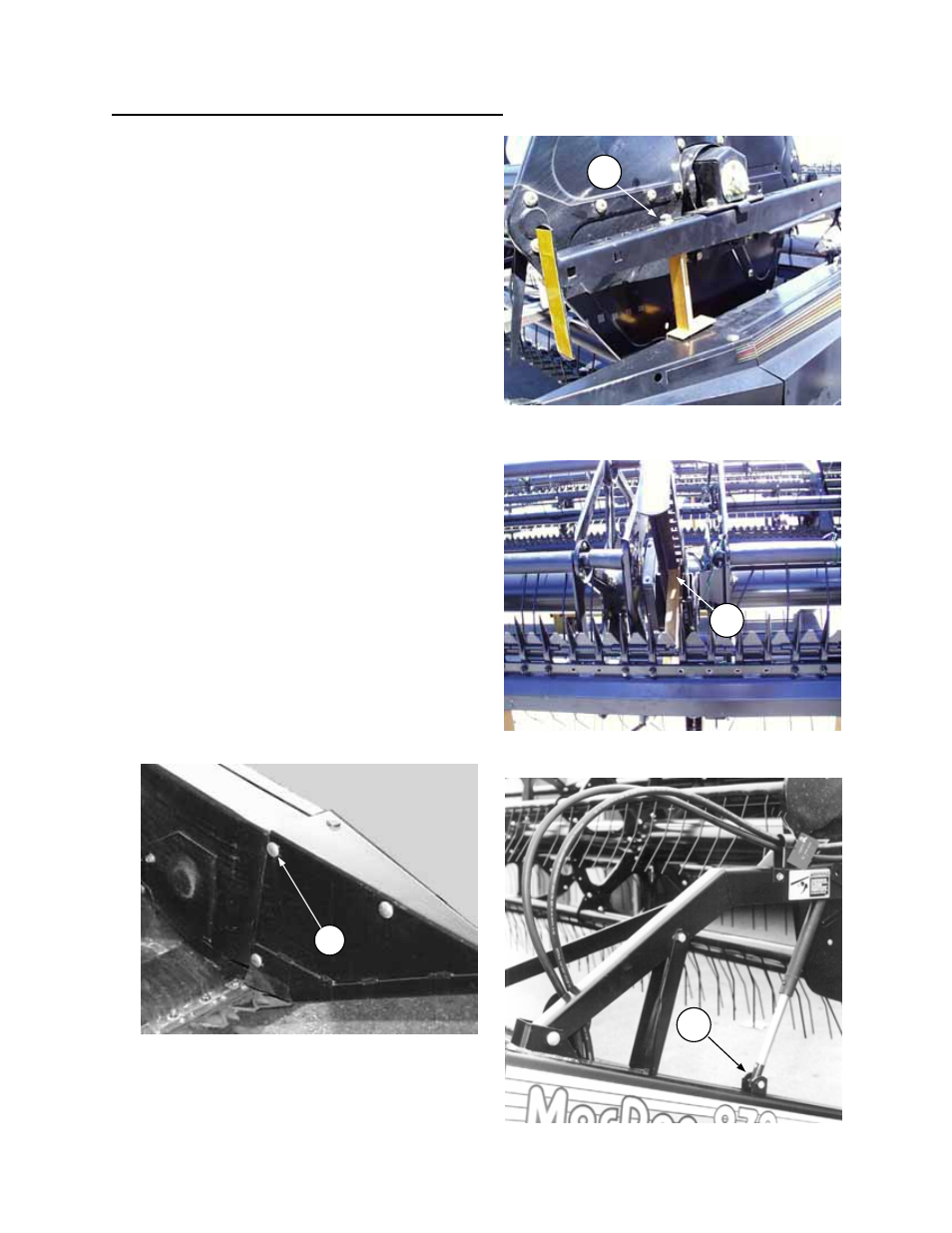

REEL SUPPORT ARMS – 30’ & 36’ Split Reel Headers

1. Drive forklift to front of header, centered on the

R/H reel. Remember L/H and R/H designations

are determined from the rear of the header, facing

forward. Place a lifting strap around reel main

tube and attach to forklift.

NOTE: To avoid damage to tube, do not lift with

forks directly under reel tube.

2. Remove nuts (A) securing yellow shipping

supports to L/H & R/H reel support arms.

3. At center of header, remove nut securing yellow

shipping support (C) to center reel support arm.

4. Raise the forks slowly to raise R/H reel. Engage

reel props at R/H end and center support arms

and lower forks until reel rests on props.

5. Disengage center reel arm shipping support from

cutterbar and discard.

6. Drive the forklift to L/H end of left reel. Place lifting

strap around reel main tube and attach to forklift.

Raise the forks slowly to raise L/H reel. Engage

reel prop at L/H end and lower forks until reel

rests on prop. Back the forklift away.

7. Remove the bolts securing left and right end

shipping supports to header frame. Discard straps

and re-install hardware. Hardware at (F) is

installed reversed for ease of access when

removing shipping supports. To prevent damage

to reel end shields and /or discs, always install

carriage head bolts to the inside of header as

shown for field use.

8. Cut shipping wire securing reel lift cylinders. At

outer arms, attach rod end of reel lift cylinder to

header at (B). At center arm, attach rod end of

cylinder to reel support arm.

REEL SUPPORT ARMS SHIPPING POSITION

A

REEL SUPPORT ARMS WORKING POSITION

B

CENTER REEL SUPPORT ARM

C

INSTALL HARDWARE WITH HEADS IN

F