Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 67

Form # 46290

Issue 09/05

65

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

Converting Sickle Drive Assembly from Windrower to Combine - 21', 25', 30' & 36' Headers

The sickle drive assembly at the left end of the 21' to 36' header varies depending on the application

(windrower or combine). For kits to convert from one drive configuration to the other see “Options and

Attachments” section of this book.

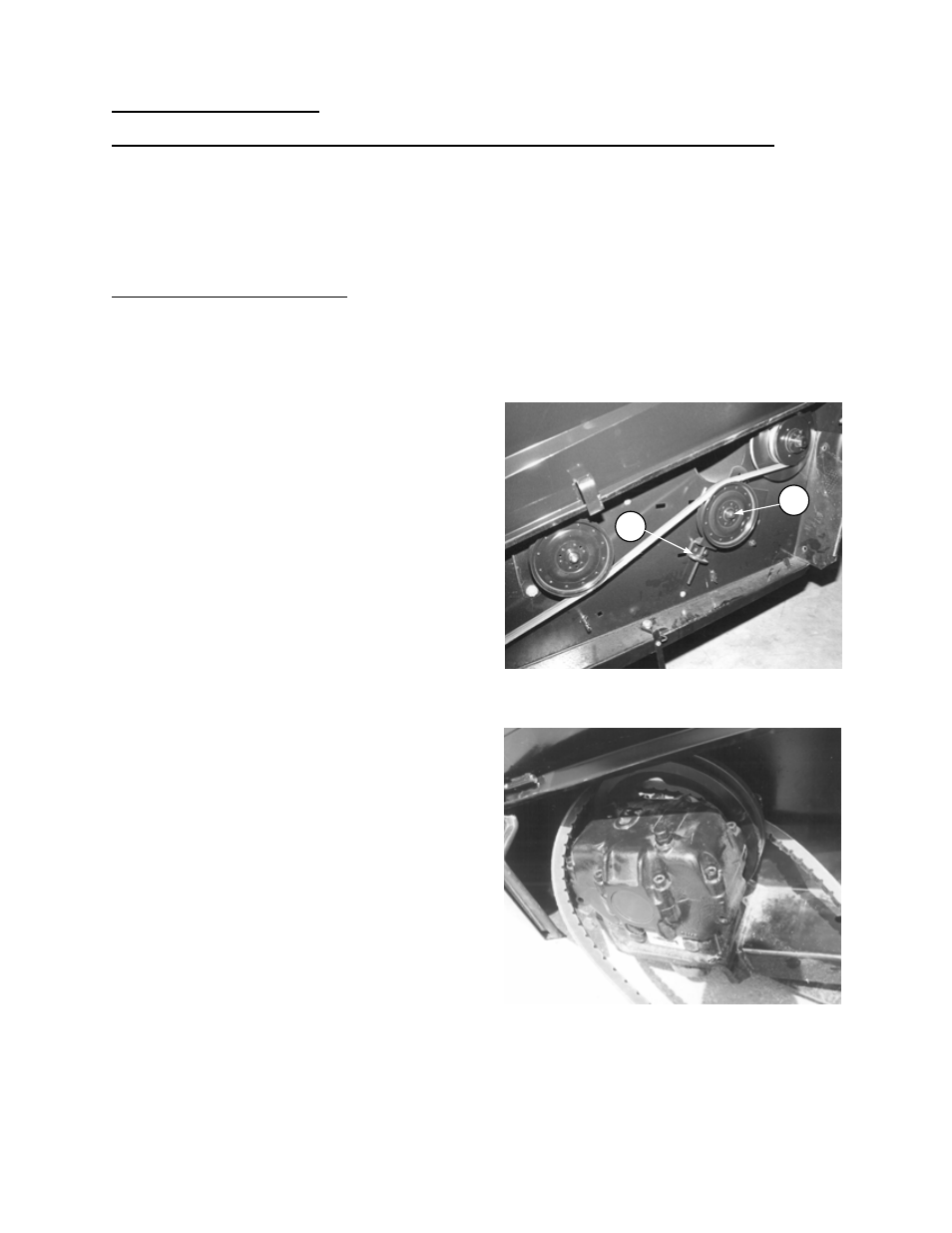

Single Sickle Drive Belt Tension

Check sickle drive belt tension after a 5 hour run-in

period and every 100 hours thereafter.

IMPORTANT: To prolong belt and drive life, do not

over-tighten belt. Operate at minimum tension required

to prevent slipping or excessive belt whip. When

installing a new belt, never pry belt over pulley. Loosen

adjusting device sufficiently to allow easy installation.

To adjust:

1. Loosen nut (A).

2. Turn nut (B) to move idler pulley up or down

(depending on drive configuration) to tighten belt

until a force of 18 lbs. (80 N) deflects belt 3/4 inch

(20 mm) at mid-span.

3. Tighten nut (A).

4. Re-adjust tension of a new belt after a short run-in

period, (about 5 hours).

NOTE: To remove belt, back off idler pulley and

remove bolt-on panel in left end sheet at wobble box.

Turn belt on edge and work it up and over pulley hub

as shown.

A

B

SICKLE DRIVE BELT TENSION ADJUSTMENT

WINDROWER CONFIGURATION SHOWN

REMOVING SICKLE DRIVE BELT