Maintenance/service – MacDon 742 HAY CONDITIONER User Manual

Page 68

Form # 46290

Issue 09/05

66

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE (continued)

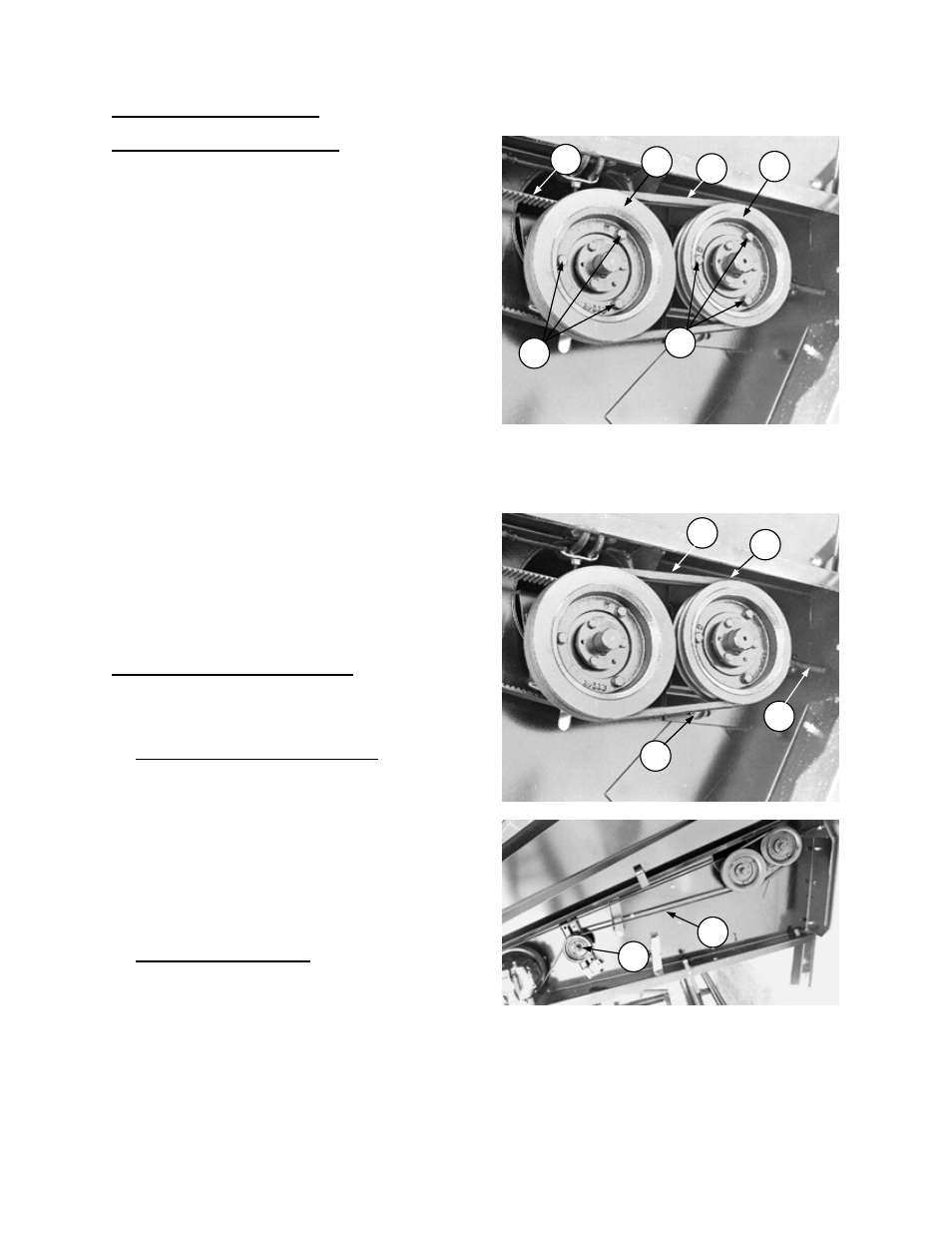

Changing Double Sickle Speed

Sickle drive is factory assembled for sickle speed

of:

12', 15' & 18': 1875 strokes per minute (spm)

21', 25', 30' & 36': 1695 spm

By exchanging pulleys (A) and (B) sickle speed

can be changed to:

12', 15' & 18': 1450 spm

21', 25', 30' & 36': 1310 spm

NOTE: Speeds listed are for windrower

applications. Sickle speed in combine applications

varies depending on combine.

To change sickle speed:

1. Loosen and remove cross-shaft drive belt (G).

See "Tightening Double Sickle Drive Belts",

below.

2. Remove three bolts (C) and separate pulley (B)

from the timing belt pulley.

3. Remove three bolts (D) and separate pulley (A)

from drive hub.

4. Exchange positions of pulleys (A) and (B) and

reassemble.

5. Tighten cross-shaft drive belt (G) and L/H

timing belt (L).

Double Sickle Drive Belt Tension

Check sickle drive belt tension after a 5 hour run-

in period and every 100 hours thereafter.

1. To tighten cross-shaft drive belt (G):

NOTE: If timing belt also requires tightening,

go to step 2.

a) Loosen two nuts (J) at driver pulley mounting

plate.

b) From outside of end sheet, turn adjusting bolt

(K) clockwise until a force of 12 lbs. (55 N)

deflects belt (G) 1/8 inch (3 mm) at mid-span.

c) Tighten nuts (J) to lock the position.

2. To tighten timing belts (L):

a) Loosen idler bolt (M)

b) Move idler pulley up until a force of 6 lbs. (28 N)

deflects timing belt (L) 1/2 inch (13 mm) at

middle of top span.

c) Tighten idler bolt (M).

d) Repeat at other side.

K

J

G

J

SICKLE DRIVE BELTS

TENSION ADJUSTMENT

M

L

CHANGING SICKLE SPEED

D

L

B

G

A

C