Orbital Antares User Manual

Page 67

Antares

®

OSP-3

User’s Guide

Section 7.0

– Ground and Launch Operations

Release 1.1

July 2013

56

7.3. Launch Vehicle Processing

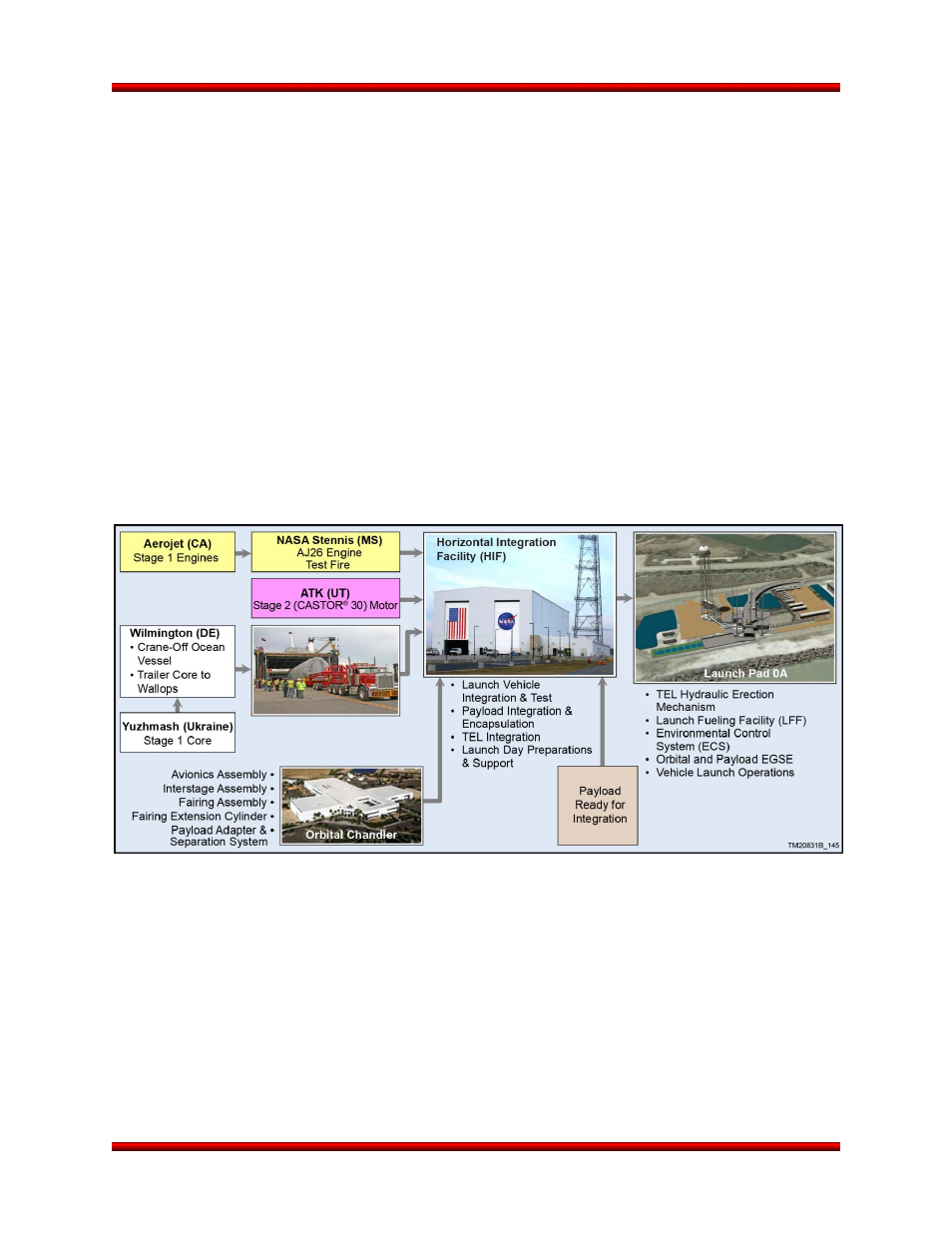

All major vehicle subassemblies are

delivered from either Orbital’s production facilities or directly from the

vendor to the HIF. Figure 7.3-1 depicts the typical flow of hardware from the factory to the launch site.

Once the major vehicle components and subassemblies are delivered to the HIF, the vehicle is horizon-

tally integrated and tested prior to the arrival of the payload. Integration is performed on platforms set at

convenient working heights, which allows relatively easy access for component installation, inspection

and test.

The transformation of engines, rocket motors, avionics, and sub-assembled structures into an integrated

launch vehicle occurs at the HIF. A small group of skilled engineers and technicians perform the follow-

ing major functions at this facility:

Receive and inspect all motors, rocket engines, subassemblies, and vehicle components

Integrate rocket engines and mechanical, electrical, ordnance components, and subassemblies to

the individual stages

Perform electrical testing of the integrated motors, composite subassemblies, and the avionics

section

Receive the payload, test interfaces, integrate the payload to the LV, and encapsulate the payl-

oad within the fairing

Figure 7.3-1. Flow of Antares Hardware to the Launch Site

7.3.1. Stage 1 Motor Core

Upon arrival at the HIF, the Stage 1 core is lifted from its overland transporter and placed on GSE using

HIF cranes. Functional checks are performed to validate electrical and pneumatic systems are properly

performing after the core’s transport. The aft bay of the core is removed providing access for avionics,

ordnance, and MES installations. Once the MES is mated the Stage 1 core, electrical, functional, and

leak checks are performed. Following this validation, the motor aft bay is reinstalled completing the Stage

1 Core subassembly.