Actuator inspection, Rotor shaft inspection, Actuator inspection 64 – MTS Series 215 Rotary Actuator User Manual

Page 64

Series 215 Rotary Actuator Product Manual

64

Actuator Inspection

Maintenance

Actuator Inspection

When the actuator is disassembled, it is recommended that the individual parts of

the actuator be examined for excessive wear and scratches or pitting. Give

particular attention to the actuator rotor shaft and radial bearings.

Rotor shaft inspection

Examination of the actuator rotor shaft should include the following:

1. Check the rotor shaft for surface wear. If the metal surfaces are pitted,

scratched, or damaged in any way, the rotor shaft may need to be replaced or

rebuilt. Contact MTS Systems for assistance.

Note

Excessive rotor shaft wear may be indicated if fluid leakage reappears

after recent replacement of the low pressure seals.

2. Check the surface dimensions of the rotor shaft with a micrometer. The

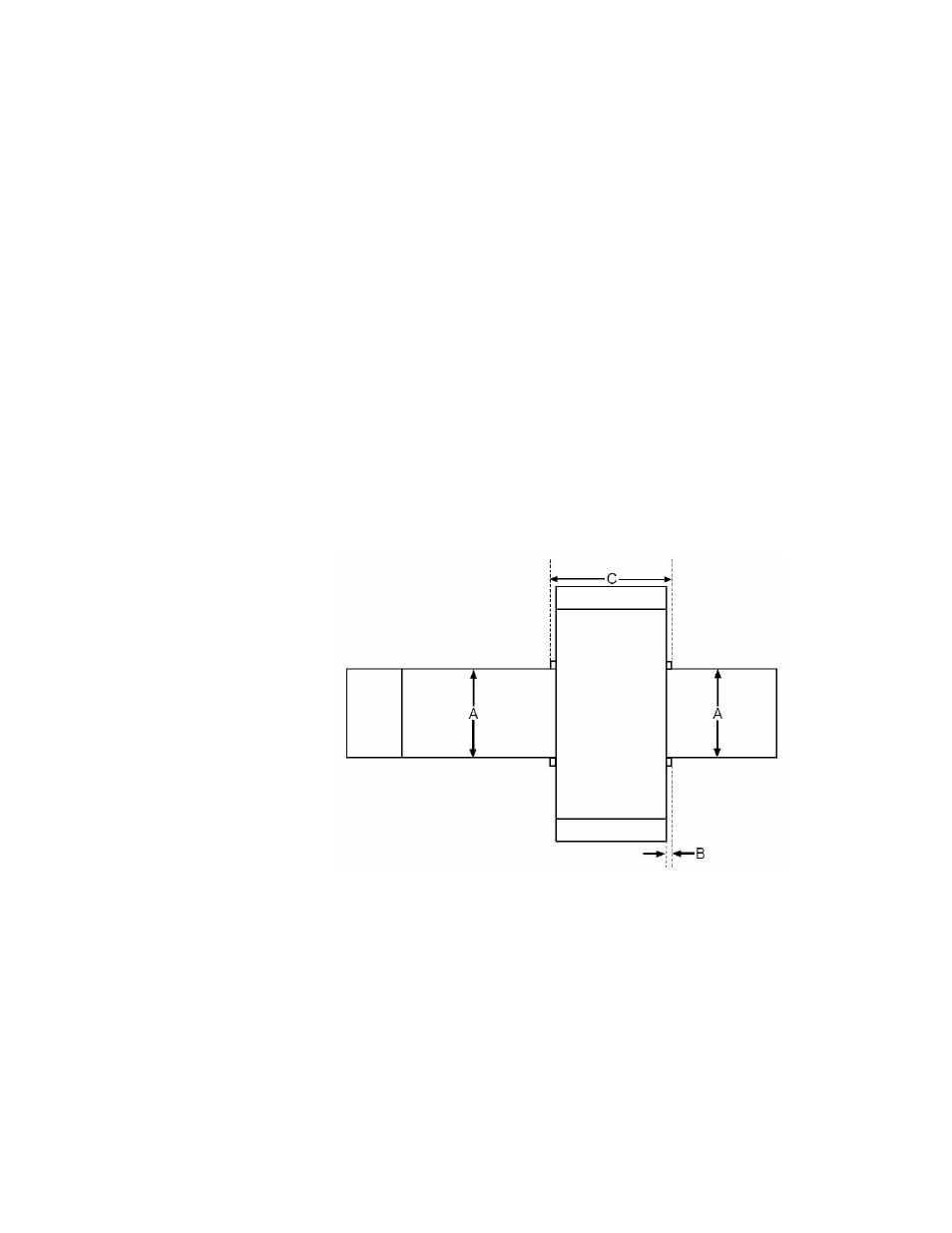

following figure indicates the locations of pertinent measurements.

3. Compare these measurements against the specifications given in the

“Actuator Rotor Dimensions” table.

If the rotor shaft dimensions are less than the minimum dimensions in the

“Actuator Rotor Dimensions” table, contact MTS Systems for assistance.

Rotor Shaft Measuring Points