Sample calculation – MTS Series 215 Rotary Actuator User Manual

Page 51

Test Setup Using Diaphragm Flexures

Series 215 Rotary Actuator Product Manual

Operation

51

Sample calculation

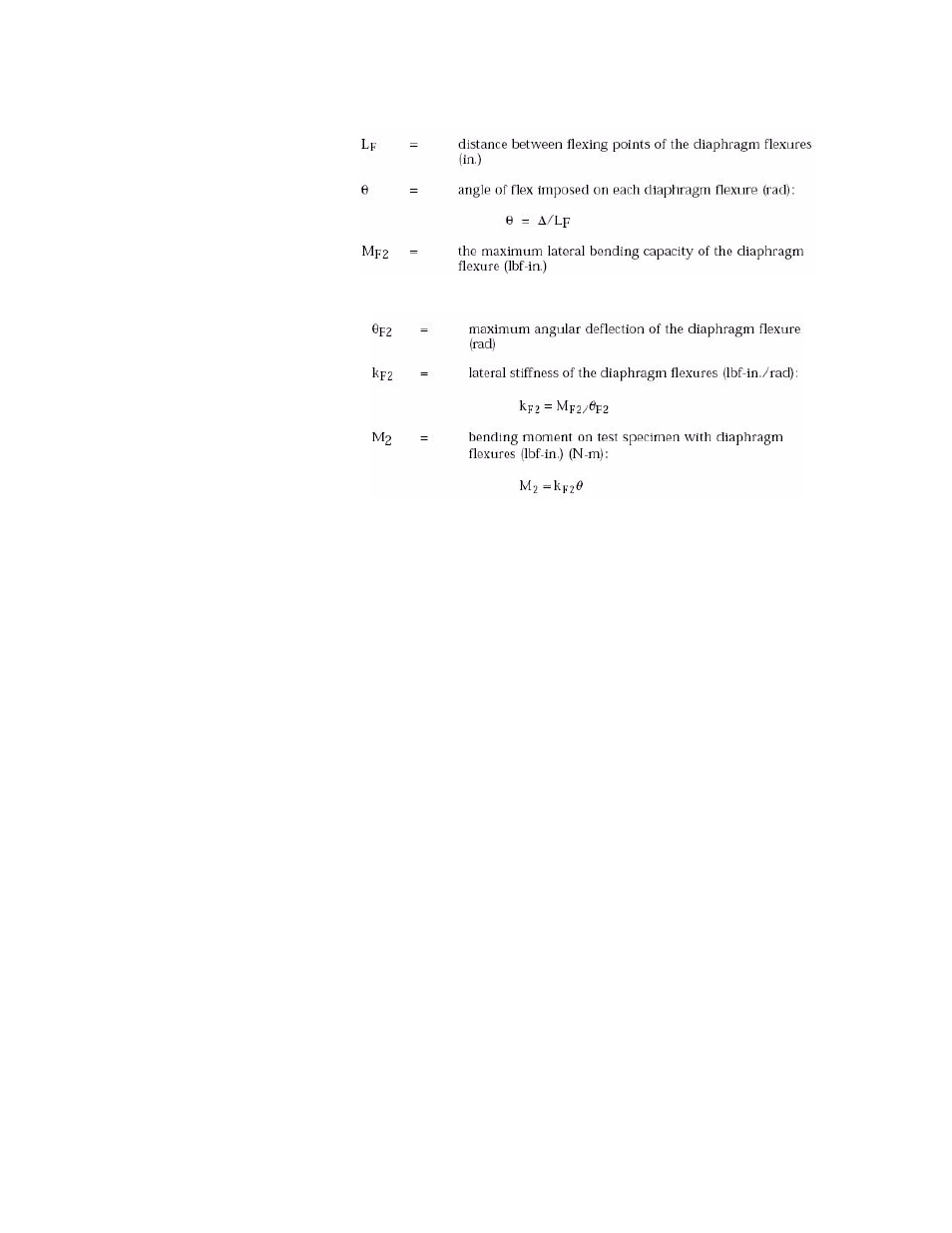

The previous figure illustrates the forces and measurements pertinent to the

calculations. Refer to the appropriate tables for ratings and dimensions of the

Model 215.45 Rotary Actuator used in the example. The following calculations

use values derived from the sample calculations performed previously.

Using the preceding formulas and following values calculate

Δ (centerline offset)

and then

θ (angle of flex on flexures). If θ is not greater than θ

F2

, the flexures are

adequate (from Table 1-7,

θ

F2

= M).

Calculate S

B

and determine if it is within acceptable limits for the specific

test.

a = 11.75 in. (Distance from actuator center line to base plate center)

k

1

= 148.5 x 10

6

lbf-in./rad. (Torsional stiffness of thin flat plate)

L

1

= 43 in. (Length of base plate subjected to twisting)

Note

Length of base plate subject twist has been changed from 37 in. to 43 in.

This was necessary because using diaphragm flexures at the ends of a

specimen increases the distance between the foot mounting and

reaction bracket. Refer to “Diaphragm Flexure Dimensions and Ratings”,

dimension C.

L

F =

13 in. (Distance between flexing points of the diaphragm

flexures) (from Diaphragm Flexure Dimensions and Ratings, rating L)

M

F2

= 400 lbf·in (Maximum lateral bending capacity of the diaphragm

flexure) (from Diaphragm Flexure Dimensions and Ratings, rating M)

θ

F2

= 0.015 rad (Maximum angular deflection of the diaphragm

flexure)

T = 50,000 lbf·in. (Applied torque)