Calculate centerline offset – MTS Series 215 Rotary Actuator User Manual

Page 47

Test Setup Using Standard Flexures

Series 215 Rotary Actuator Product Manual

Operation

47

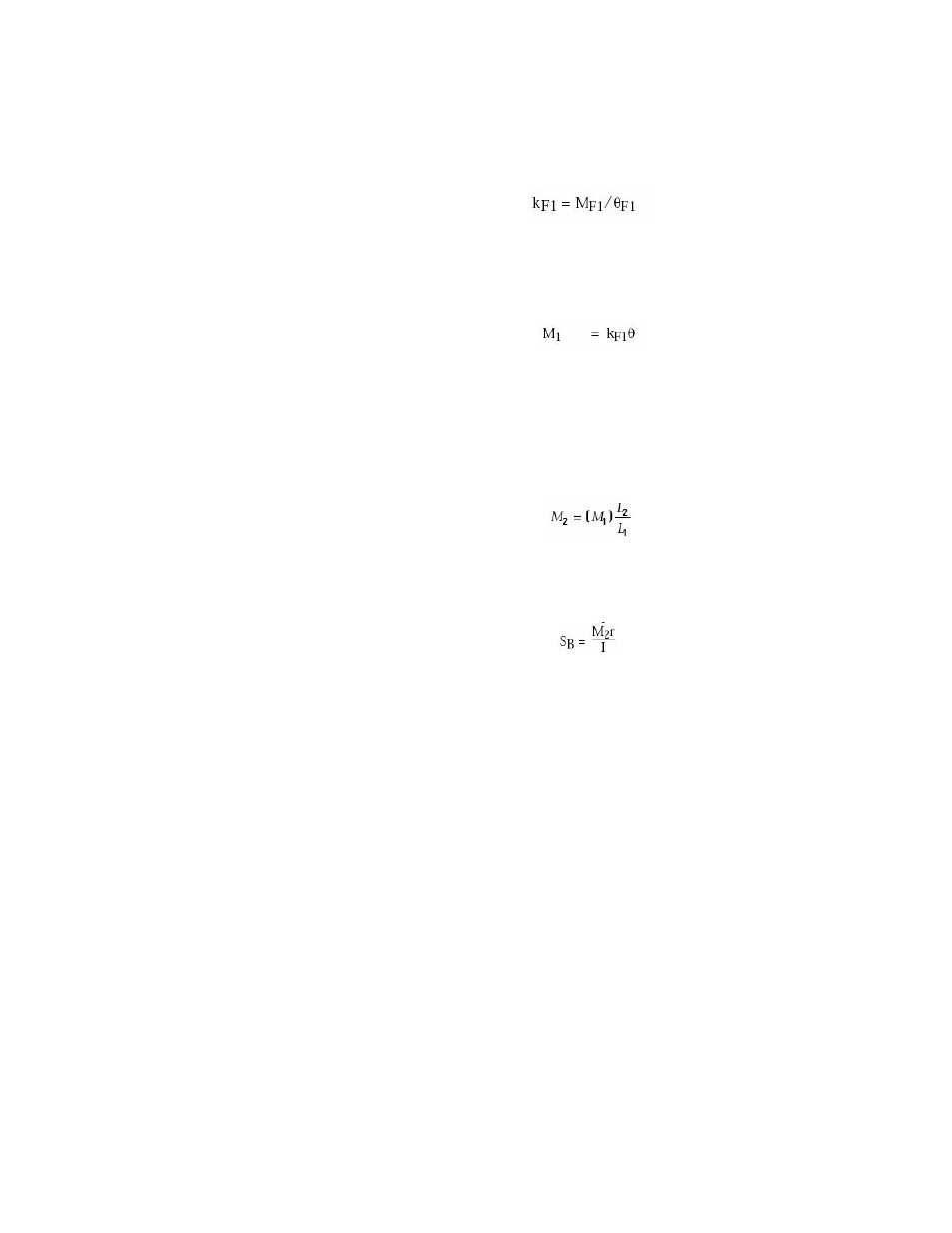

k

F1

= Angular horizontal stiffness of actuator and reaction bracket (N·m/rad)

(lbf·in./rad):

M

1

= Bending moment on actuator and reaction bracket with standard flexures

installed (N·m) (lbf·in.):

M

F1

= Maximum horizontal bending capacity of standard flexures (N·m)

(lbf·in.).

M

2

= Bending moment on specimen with standard flexures installed (lbf·in.)

(N·m):

SB = Bending stress on test specimen due to base plate twisting (N/m

2

) (psi):

The previous figure illustrates the forces and measurements pertinent to the

calculations. Refer to the appropriate tables for ratings and dimensions of the

Model 215.45 Rotary Actuator used in the example.

The following procedure uses sample values. When performing the calculations

to determine the anticipated test forces, the values appropriate to your specific

test should be substituted for the sample values. In addition, the example uses

U.S. Customary units of measure.

Use the following values and formulas to calculate

Δ (centerline offset) and then

θ (angle of flex on flexures). If θ is not greater than θ

F

1, the standard flexures are

adequate.

Also calculate SB, the bending stress on the specimen under test. If SB is above

the determined maximum tolerable value, diaphragm flexures must be used in the

test setup.

Calculate centerline

offset

Calculate the centerline offset (D) between the actuator and reaction bracket

mountings due to base plate twist by using the following formula: