Actuator specifications, Actuator specifications 16 – MTS Series 215 Rotary Actuator User Manual

Page 16

Series 215 Rotary Actuator Product Manual

16

Actuator Specifications

Introduction

As the block diagram shows, a program command signal is input to the

controller. The command signal is compared to the feedback signal from one of

the actuator transducers. If the command signal equals the feedback signal from

the transducer conditioner, no DC error is present and the valve driver circuit

produces little or no servovalve control signal. If the command signal does not

equal the feedback signal, a DC error signal is sent to the valve driver circuit.

The valve driver circuit uses this signal to generate a servovalve control signal.

The servovalve control signal causes the servovalve spool to open in a direction

and by an amount necessary to direct a regulated flow of hydraulic fluid to the

actuator’s pressure or return ports. The actuator moves in response to the flow of

hydraulic fluid. The constant feedback of the closed-loop system enables the

controller to maintain precise control of actuator torque or movement.

Actuator Specifications

Series 215 Rotary Actuators are available in six models. This section lists

specifications for both the Series 215 Actuator and its options.

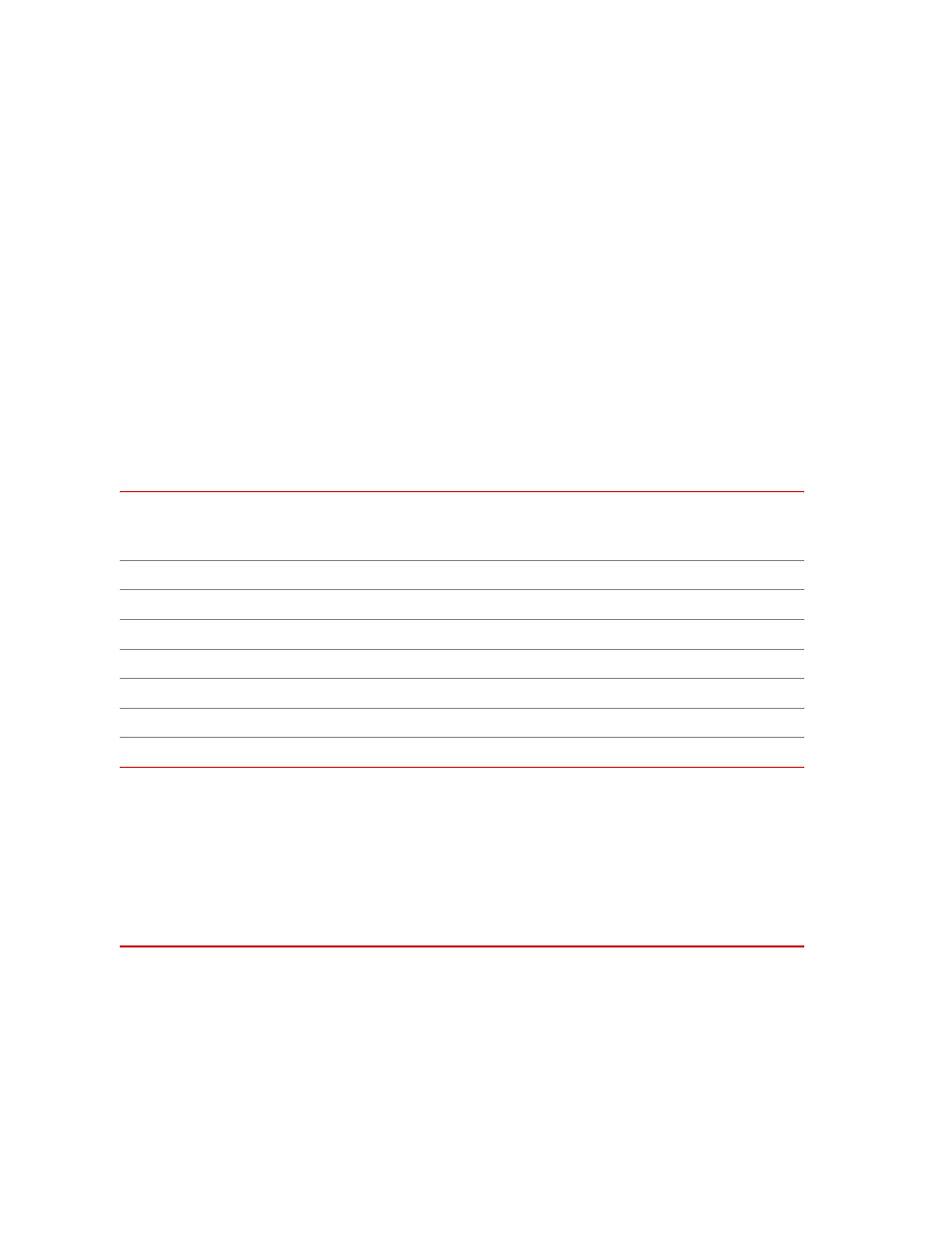

Series 215 Rotary Actuator Ratings by Model

M

ODEL

R

ATED

T

ORQUE

*

D

ISPLACEMENT

T

HRUST

L

OAD

Q (M

AXIMUM

)

S

IDE

L

OAD

†

P (M

AXIMUM

)

B

ENDING

M

OMENT

M (M

AXIMUM

)

lbf·in.

N·m

in.

3

/rad

cm

3

/rad

lbf

kN

lbf

kN

lbf·in.

N·m

215.32

2000

226

0.80

13.1

750

3.3

1500

6.67

3600

405

215.35

5000

565

1.9

31.1

750

3.3

3500

15.57

15,400

1732

215.41

10,000

1130

3.7

60.6

750

3.3

3500

15.57

15,400

1732

215.42

20,000

2260

7.2

117.9

750

3.3

3500

15.57

17,300

1946

215.45

50,000

5650

19.0

311.3

1200

5.3

5700

25.36

43,000

4837

215.51

100,000 11,300

38.0

622.7

1200

5.3

6500

28.92

50,000

5625

* Actuator is designed for cyclic use at rated torque: rated at maximum differential pressure at 21 MPa

(3000 psi).

† P and M are interdependent: if P is at maximum, M must be zero; if P = 75% of maximum, M may

be up to 25% of its maximum value.

‡ If these values are to be exceeded, additional internal or external cushions are required; contact

MTS.

§ w = rotational velocity in rad/sec and J or I = rotational inertia in lbm-in.

2

or kg-m

2

including inertias

from rotary actuator, flange, flexure, and 1/2 of test specimen (lbm = pounds mass).

¶ Does not include flange adapter.