Actuator installation, Reaction bracket and torque cell installation – MTS Series 215 Rotary Actuator User Manual

Page 32

Series 215 Rotary Actuator Product Manual

32

Actuator Installation

Installation

Actuator Installation

Typically, the Series 215 Rotary Actuator is first bolted to a foot mounting

assembly, then positioned on a base plate or T-slot table and secured with lightly

lubricated mounting bolts. The foot mounting dimensions and ratings must match

the actuator in use. After completing the alignment of force train components,

torque the bolts to the correct values.

Reaction Bracket and Torque Cell Installation

The reaction bracket should be positioned at the opposite end of the base plate or

T-slot table from the actuator. Ensure that it is oriented with the smooth vertical

surface facing the actuator.

Lightly lubricate the reaction bracket mounting bolts and hand-tighten them to

secure the position of the reaction bracket. The reaction bracket mounting bolts

should not be fully tightened until the force train components are aligned. Refer

to the appropriate table for the reaction bracket force ratings and the torque

values used when installing the reaction bracket and torque cell.

In most cases the selected torque cell bolts directly to the surface of the reaction

bracket. When possible, the side of the torque cell that attaches to the center

collar should be bolted to the reaction bracket. This configuration will cause the

least movement of the torque cell electrical cable. The torque cell and reaction

bracket should be bolted together with the correct torque value. It may be

necessary to temporarily tighten the reaction bracket mounting bolts to keep it

from moving while the torque cell is bolted in place.

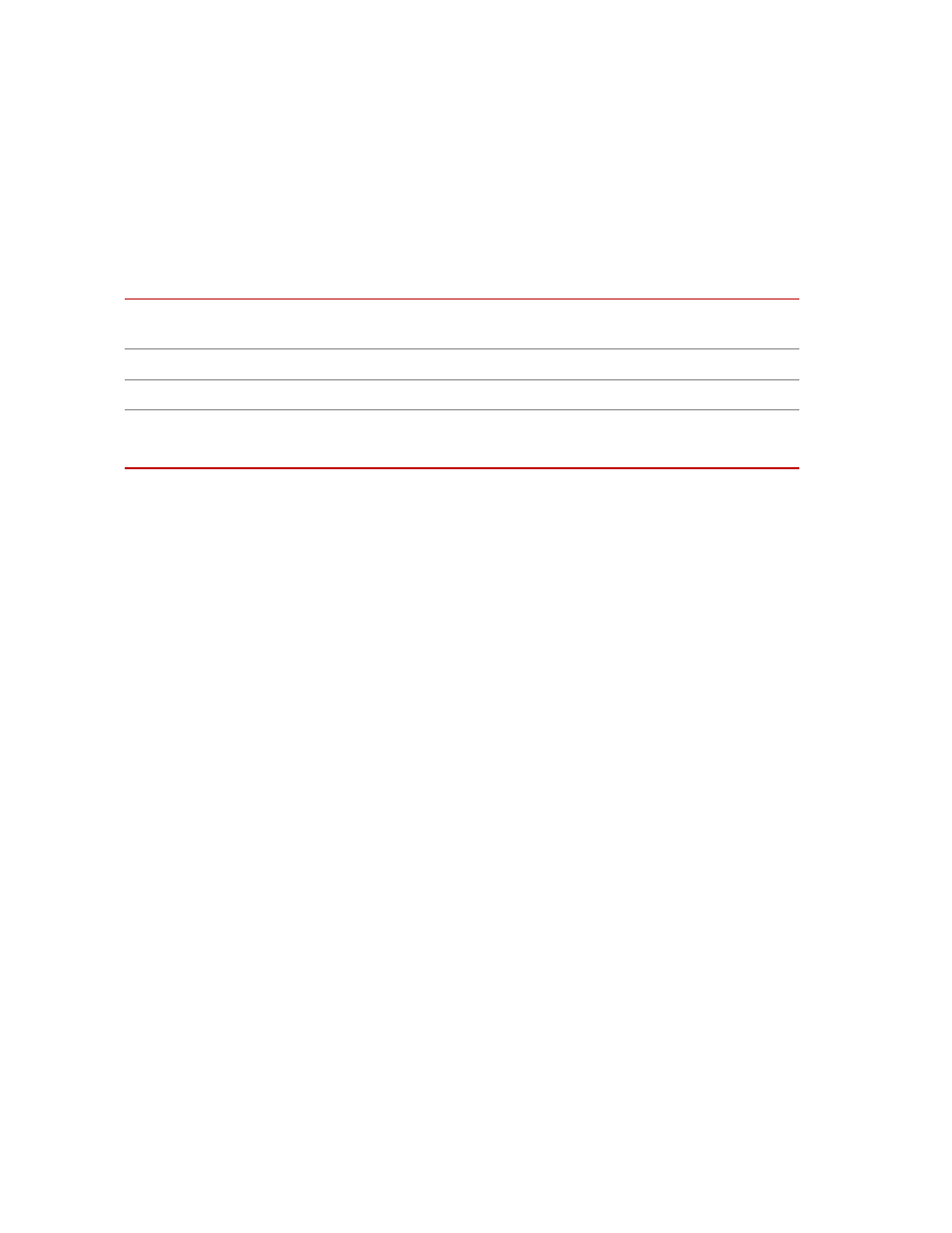

Actuator Mounting Bolt Torque Values

M

ODEL

A

CTUATOR

A

SSEMBLY

TO

F

OOT

M

OUNTING

F

OOT

M

OUNTING

TO

B

ASE

P

LATE

OR

T-S

LOT

T

ABLE

LBF

·

FT

N·

M

LBF

·

FT

N·

M

215.32, 215.35

35

47

150

204

215.41, 215.42

215.45, 215.51

80

110

150

204