2 troubleshooting the instrument – INFICON XTM/2 Thin Film Deposition Monitor User Manual

Page 106

6 - 4

IP

N 07

4-

18

6S

XTM/2 Operating Manual

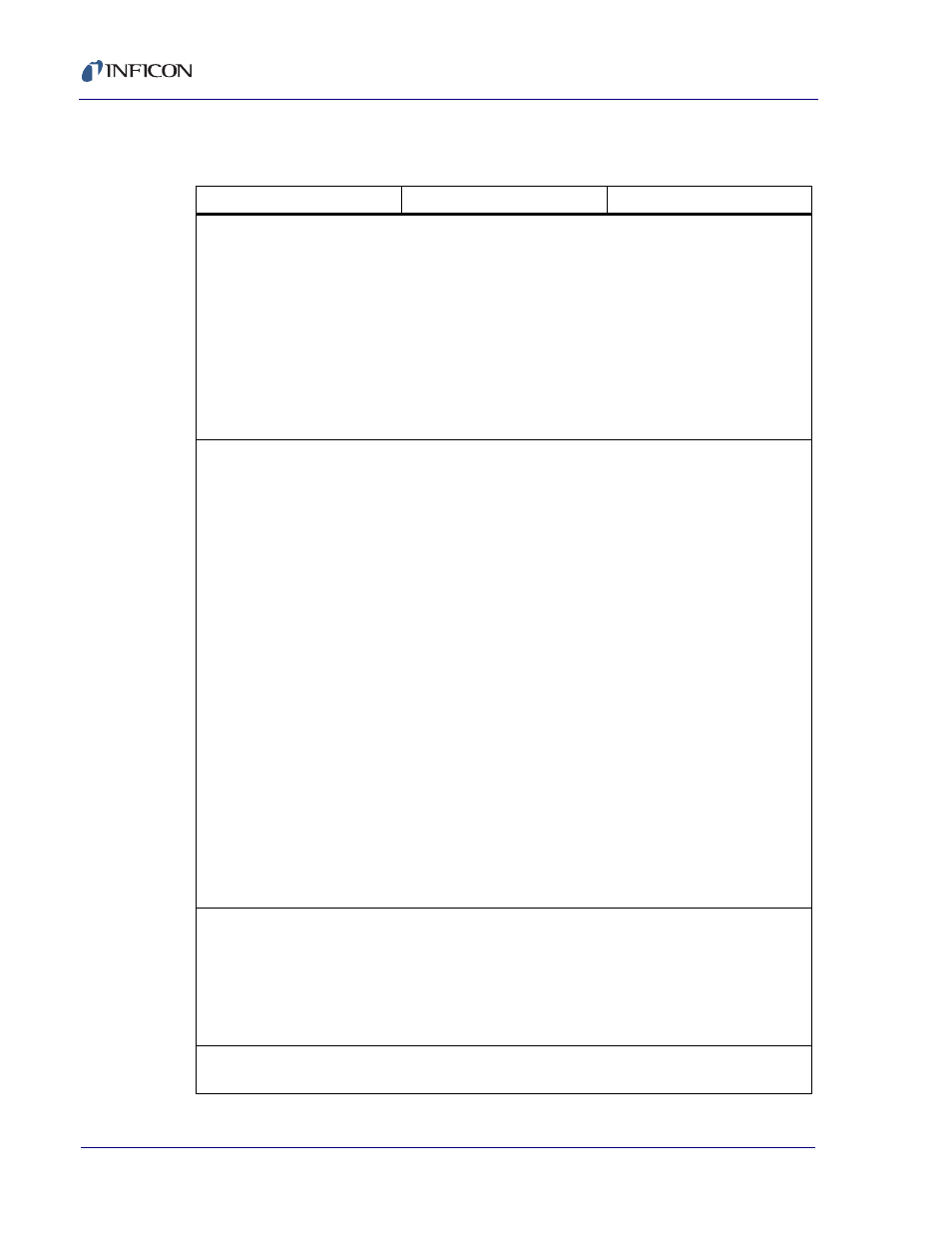

6.3.2 Troubleshooting the Instrument

Table 6-1 Troubleshooting the Instrument

SYMPTOM

CAUSE

REMEDY

1. power on LED not

illuminated

a. blown fuse/circuit breaker

tripped

a. have qualified personnel

replace fuse/reset circuit

breaker

b. electrical cord unplugged

from wall or back of

instrument

b. re-connect power cord

c. incorrect line voltage

c. have qualified personnel

verify line voltage, verify the

instrument is configured for

the correct voltage

2.unit "locks" up

a. cover or back panels not

attached to the instrument.

a. ensure all covers and

panels are in place and

securely fastened

b. high electrical noise

environment

b. re-route cables to reduce

noise pickup (1’ (305 mm)

away from high power

conducting lines makes a

sizeable reduction in the

amount of noise entering

the instrument), keep all

ground wires short with

large surface area to

minimize ground

impedance

c. poor grounds or poor

grounding practice

c.verfify proper earth

ground, use appropriate

ground strap, eliminate

ground loops by

establishing the correct

system grounding, verify

proper instrument

grounding

3. instrument does not

retain parameters on power

down (loss of parameters

on power up)

a. faulty static RAM

a. SRAM battery has a

normal life expectancy of

ten years, contact INFICON

service department

b. power supply problem

b. contact INFICON service

department

4. some keys on front panel

function while others do not

a. faulty keypad or faulty

keypad ribbon cable

a. contact INFICON service

department