Enerpac ATM-9 User Manual

Page 7

77

13.0 TROUBLESHOOTING

Problem 1:

The hydraulic cylinder is sliding on the circumference of

the opposite flange as the ATM-9 is aligning the joint.

Cause:

Grit or dirt on wing, rollers or bearings, wing is at full

extension.

Solution:

A. Ensure the rollers are rotating freely and that there is

no restriction to the rollers on the wing surfaces such

as dirt or grit.

B. Check that the wing is not at full extension when

aligning the joint.

C. Ensure that there is enough extension left to allow

the ATM-9 to expand as the joint is aligned.

Problem 2:

The ATM-9 is attached and appears to be functioning

properly, but the joint will not align.

Cause:

A. There may be air in the hydraulic system restricting

the force on the flanges.

B. There may be something restricting the joint at a

point close to the flanges. The joint may require more

than 9 ton [90 kN] pressure to align.

Solution:

A. See air lock removal instructions in section 14.

B. Check the area around the joint to establish if there

is an obstruction to the joint.

C. If the joint requires more force than that of the 9 ton

[90 kN] capacity of the tool, then another method to

align the joint should be adopted.

14.0 AIR LOCK REMOVAL

Remove air as described in the following steps:

1. Remove the air vent cap on top of the hydraulic

pump and check hydraulic oil level to ensure there is

enough oil to advance the cylinder.

2. Replace air vent cap, but do not tighten the cap.

The cap must remain loose (in the “vent” position) to

allow air to enter and leave the pump during use. The

cap should only be tightened fully when the tool is to

be returned to the carrying case after use.

3. With the air vent cap loose, connect the pump to

the tool with the hydraulic hose supplied within the

carrying case.

4. Stand the tool on a level surface, hold the hydraulic

pump above the tool, close the release valve on the

pump, and prime the pump to advance the hydraulic

cylinder until the cylinder is fully advanced and a

small pressure is achieved.

5. With the hydraulic pump held above the tool, open

the release valve allowing the cylinder to retract fully

back. While the cylinder is retracting any air that is

within the system will be forced up to the pump and

vented out through the air vent cap.

6. Repeat the above procedure three or four times to

ensure that all air is removed and the tool will reach

full working pressure.

15.0 MINIMUM / MAXIMUM EXTENSION

Refer to section 18.0, Weights and Dimensions, for

minimum and maximum extension information.

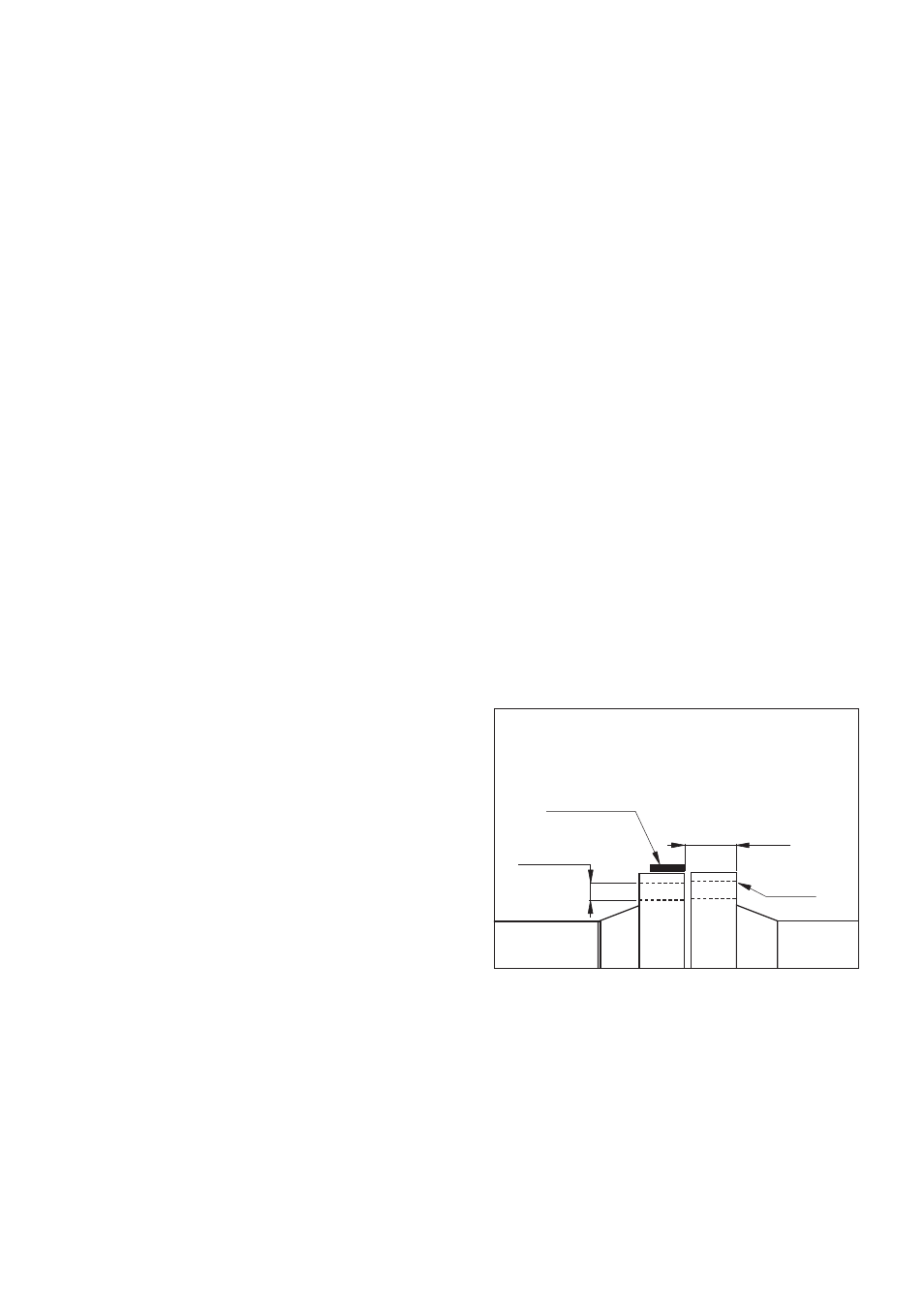

16.0 APPLICATION RANGE

Two basic dimensions, A and B, will determine if the

ATM-9 can be used to align the joint. If the flange joint

to be aligned is between 3.66 inch [93 mm] and 9 inch

[228 mm] as illustrated by (A), has a bolt hole size of

1.24 inch [31,5 mm] or greater (B), then the ATM-9 can

be attached and alignment achieved (see fig. 14).

See charts in section 17: by flange type, class and

diameter.

Fig. 14 – Min. and max. flange sizes (visual)

Min. bolt hole size

1.24 inch [31,5 mm]

Min. distance 3.66 inch [93 mm]

Max. distance 9 inch [228 mm]

Hook into this

bolt hole

Saddle of hydraulic

cylinder must rest fully on

the circumference of the

flange to be pushed.

A

B