Enerpac ATM-9 User Manual

Page 4

4

7.0 INSTALLATION AND OPERATION

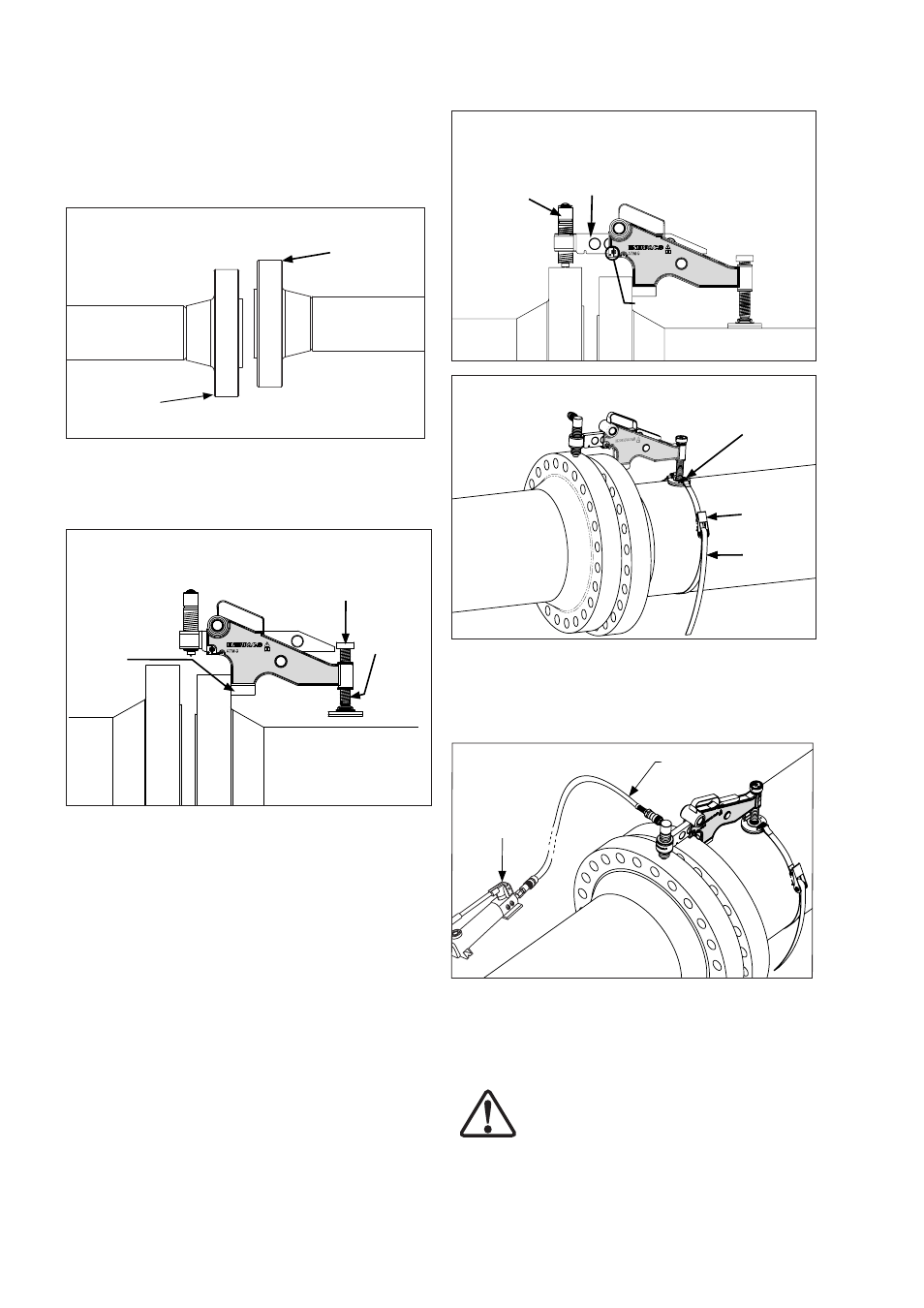

1. Determine the maximum points of misalignment.

(see Fig. 3). The maximum points are on the top or

bottom of the joint, as illustrated by the arrows.

Point of Max.

Misalignment

Point of Max.

Misalignment

Fig. 3

2. Guide the lift hook of the tool into the bolt hole at the

maximum point of misalignment. Then, adjust the

drop leg down onto the pipe by turning the adjusting

knob in the clockwise direction (see Fig. 4).

Fig. 4

Lift Hook

Adjusting

Knob

Drop

Leg

Note: The tool should be held up level within the bolt

hole during adjustment. The tool must remain parallel to

the pipe at all times.

3. Pull out the lock pin and extend the wing out to the

desired distance (see Fig. 5). Rotate the cylinder

clockwise until it locates onto the surface of the

opposite flange. At this stage, ensure that the tool is

sitting level and that the end of the cylinder is in full

contact with the surface of the higher flange.

4. Attach the hook of the strap through one of the slots

on the buckle (located above the drop leg pad).

Place the hook of the ratchet through the other slot

on the opposite side of the buckle. Feed the end

of the strap through the ratchet and tighten. (see

Fig. 6).

Fig. 5

Hydraulic

Cylinder

Wing

Wing Lock Pin

Fig. 6

Ratchet

S trap

Buckle

5. Connect the P-142 hydraulic pump to the hydraulic

hose, and the hose to the hydraulic cylinder. Operate

the pump handle until the joint comes into alignment.

(see Fig. 7).

Fig. 7

Hydraulic

Hand Pump

Hydraulic

Hose

Note: The ATM-9 hydraulic cylinder is rated at 10,000

psi [700 bar] operating pressure. The P-142 hydraulic

pump contains a built-in safety relief valve that opens

at approximately 10,500 psi [724 bar].

WARNING: If a different pump is used in

place of the P-142 for any reason, be certain

that the pump relief valve is not set higher

than 10,500 psi [724 bar]. Install a pressure gauge in

the circuit to monitor system pressure.