Enerpac ATM-9 User Manual

Page 6

66

10.0 INSPECTION AND EXAMINATION

• After finishing the job and before the ATM-9 is

placed back into service, the completeness of the

tool must be established and items examined to

ensure that they are serviceable.

• Any missing or damaged items are to be replaced

as soon as possible and prior to the tool being

used again.

• Grease all moving parts regularly. Refer to section

12.0, Lubrication and Maintenance.

• Cap or plug all open hydraulic fittings to prevent

dirt entry. Be sure that pump air vent cap is in the

“closed” position.

• Ensure rollers and pins remain grit free.

• Return all items to the carrying case when not in

use.

11.0 STORAGE

• Cap or plug all open hydraulic fittings.

• Smear machined surfaces with grease.

• Store the ATM-9 in a cool dry place.

12.0 LUBRICATION AND MAINTENANCE

Use Mobilgrease XHP ™ 222 Special grease or an

equivalent good quality high load bearing grease.

Always ensure that the wing of the tool is grit-free and

that the rollers rotate freely and are well lubricated (see

Fig. 13). This will enhance the tool’s performance and

help prolong its service life.

Clean, inspect and lubricate the ATM-9 as described in

the following steps:

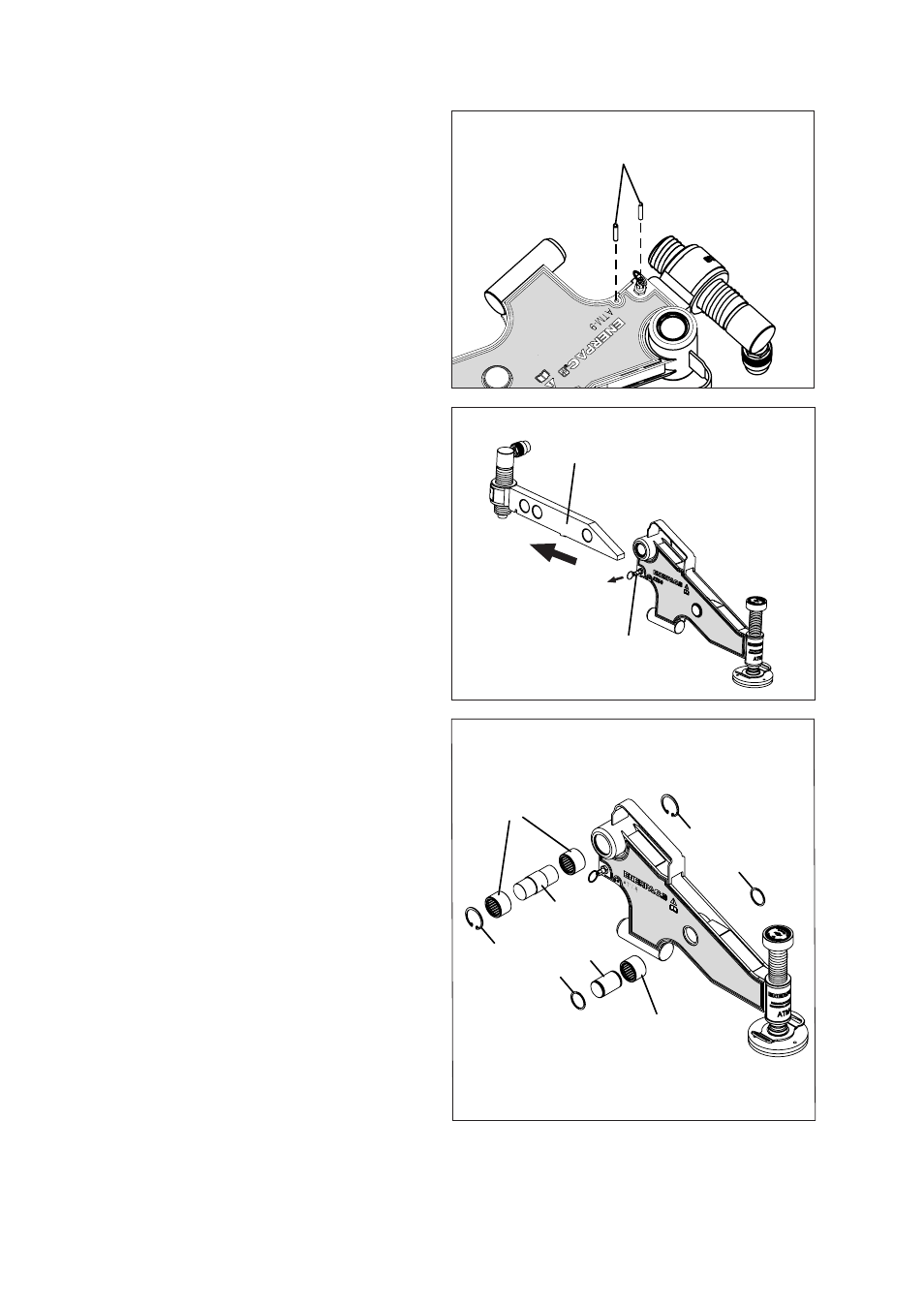

STEP 1. Place tool flat on work bench.

STEP 2.

Remove two spring pins on the front of the

main body (see Fig. 11).

STEP 3.

Pull the wing lock pin out. Remove the

wing from the main body by sliding it

forward (see Fig. 12).

STEP 4.

Remove the circlips using a circlip pliers

(see Fig. 13).

STEP 5.

Slide the roller shafts out in order to remove

the rollers and bearings for examination.

(see Fig. 13).

STEP 6.

Inspect the roller shafts, rollers and bearings

for damage, If there is no damage present,

then these parts can be cleaned, greased and

reassembled (reverse steps 1 through 5).

Fig. 11

Spring Pins

Wing

Fig. 12

Wing Lock Pin

1. Rollers and Bearings

2. Circlips

3. Roller Shafts

1

1

2

2

3

2

2

3

Fig. 13