Enerpac ATM-9 User Manual

Page 3

33

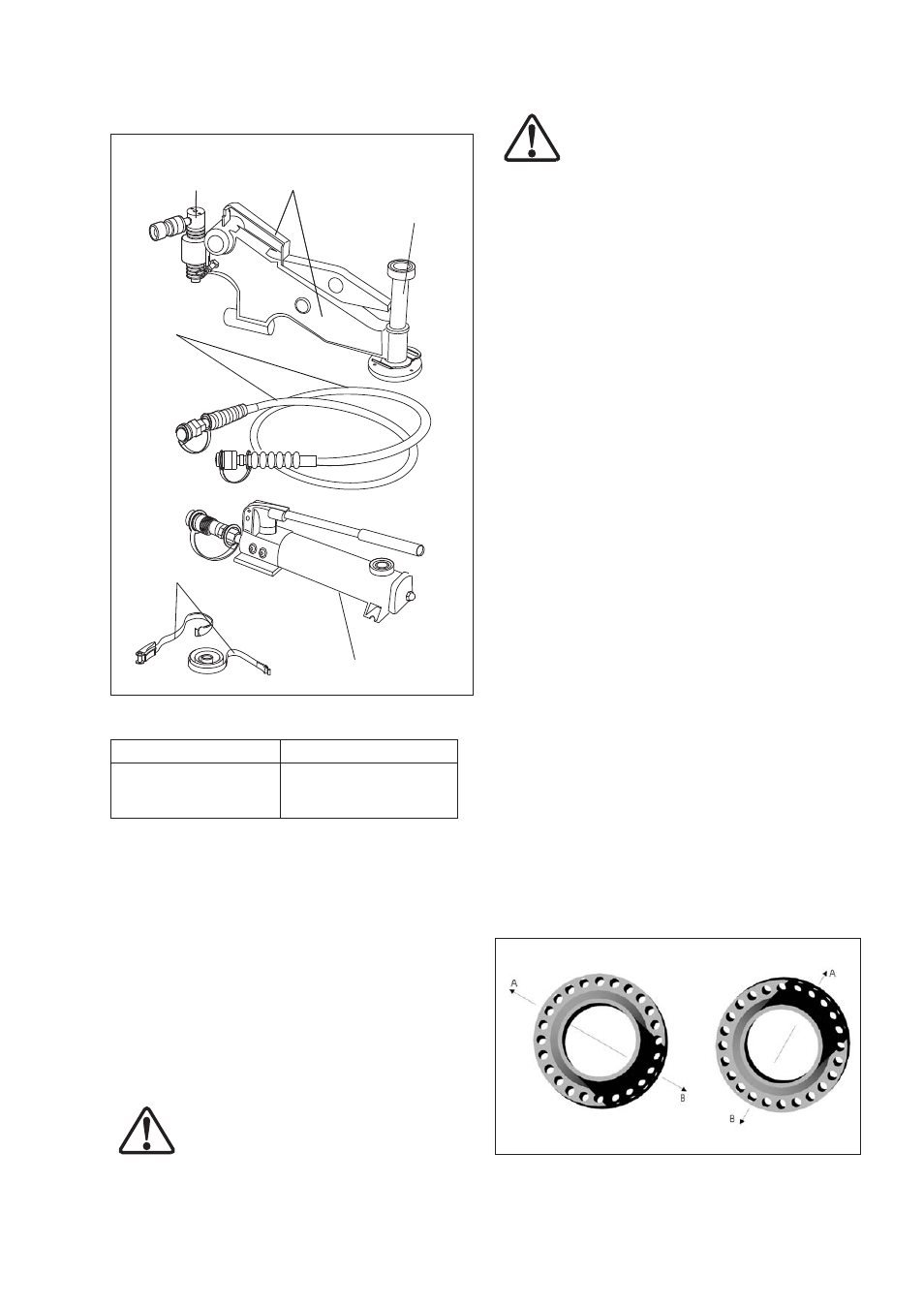

3.1 Major Features and Components

Fig. 1

Drop Leg

Hydraulic

Cylinder

P-142 Hydraulic Pump

Hydraulic

Hose

ATM-9

Tool

Strap

3.2 Technical Data

Tool Description:

Aligning Force:

Hydraulic fixed flange

and rotational alignment

tool.

9.0 T [90 kN]

from 10,000 psi [700 bar]

of hydraulic pressure.

Note: Refer to section 18.0 for weights and dimensions.

4.0 SAFETY INFORMATION

IMPORTANT: In all installations the site safety

requirements must be adhered to. The safety of the

operator and any assisting personnel is of paramount

importance along with the safety of others including the

general public.

These instructions are intended only to cover the safe

operation of ATM-9 during a normal maintenance and

installation operation. All other safety aspects must be

controlled by the operation supervisor.

CAUTION: The ATM-9 must not be attached

to pressure vessel nozzles.

WARNING: Never attach the ATM-9 to a

joint until after the flange bolts have been

loosened and removed. Overloading may

occur if bolts are removed while the tool is installed,

and the resulting force is greater than the safe working

load of the tool.

5.0 LIST OF EQUIPMENT

The tool set includes:

• ATM-9 alignment tool with hydraulic cylinder.

• Hydraulic hose, 6 feet [1,8 m] long.

• P-142 hydraulic hand pump.

• 3/8 inch NPTF couplers on hose, cylinder and pump.

• Ratchet and strap.

• Instruction sheet.

• Carrying case.

Note: All hydraulic components are rated for 10,000

psi [700 bar] operation.

6.0 MISALIGNMENT DETERMINATION

PROCEDURE

• The ATM-9 must not be attached to a flanged joint

prior to the misalignment determination procedure

being carried out. Refer to warning statement in

section 4.0.

• Every second bolt should be loosened and removed.

Continue with this procedure. Misalignment may

not occur until only a few bolts remain. At this point

the direction of any misalignment should become

obvious.

• The ATM-9, once attached, will directly push against

the misalignment, bringing the joint back into

alignment.

Example: Misalignment in various directions

A flanged joint, once broken down, may spring out of

alignment at any point, or in any direction around.

See Fig. 2. The ATM-9 should be attached at the

maximum point of misalignment i.e. A or B. Each

example shows where ATM-9 should be attached.

Fig. 2