Enerpac ATM-9 User Manual

Page 5

55

6. When alignment is completed, the flange bolts may

be inserted and tightened. After replacing all of the

bolts in all open bolt holes (except for the bolt hole in

which the tool lift hook is inserted), remove the tool

by reversing steps 1 through 5.

CAUTION: Open pump release valve and be

sure that all hydraulic pressure is relieved

before disconnecting any hoses or fittings.

7. After removing the tool from the flange, insert and

tighten the last flange bolt in the remaining bolt hole.

8.0 ROTATIONAL OR TWIST MISALIGNMENT

This is a common problem on both onshore and

offshore pipeline installations (see Fig. 8). Quite often

the flanges are in alignment but the operator is unable

to fit the bolt into any two corresponding bolt holes on

the joint‘s circumference. The ATM-9, with its 90 kN [9

ton] capacity, has the ability to manipulate the flanges

in various directions.

The set-up procedure is the same as before with one

possible exception. The ATM-9 can be attached to

the most accessible point on the joint‘s circumference

because the misalignment occurs at all bolt holes to the

same degree.

8.1 The recommended operating procedures are:

1. Select the most convenient or accessible point on

the joint‘s circumference and attach the tool there.

(Follow steps 1 thru 5 in section 7.0).

2. In the situation when both flanges are aligned but

rotational misalignment is present the ATM-9 is used

to push the flanges beyond alignment until one pair

of bolt holes become parallel (see point A in Fig. 8).

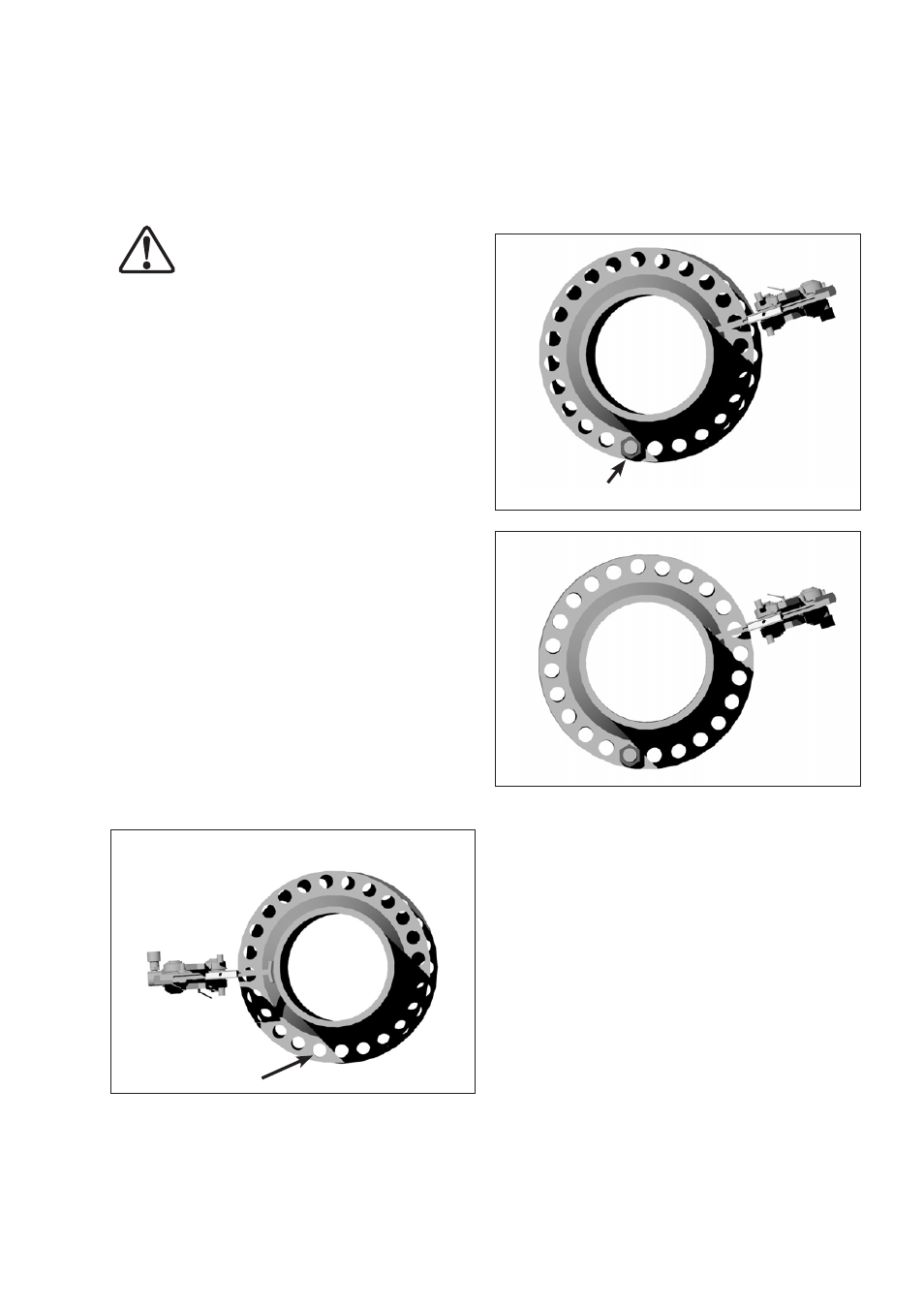

Fig. 8

A

3. Insert the bolt into the bolt hole at point A and

then release ATM-9. The load will transfer onto the

inserted bolt.

4. The ATM-9 can then be attached at another point on

the joint‘s circumference (see Fig. 9) pushing against

the inserted bolt. Advance the hydraulic cylinder until

another, or all the bolt holes are parallel (see Fig. 10).

5. Once the remaining bolts are inserted, the ATM-9

can be removed.

Fig. 9

A

Fig. 10

Please note that in some situations the operator may

have to ‘chase’ the misalignment around the joint‘s

circumference and attach the ATM-9 at several different

positions to rectify the misalignment. On each occasion

the procedures outlined in steps 1 to 7 in section 7.0

should be followed.

9.0 DISMANTLING THE ATM-9

• Once alignment is achieved, all work on the joint

finished, and bolt-up completed (apart from the bolt

hole in which the ATM-9 is located), the tool can be

removed from the joint by reversing steps 1 thru 5 in

section 7.0.

• Care should be taken not to drop any of the

component parts when removing them from the

aligned joint. This action will prevent injuries

personnel.

Note: Refer to the ATM-9 repair parts sheet for

complete parts list and assembly diagrams.