Installation instruc tio ns – Poison Spyder JK ROCKER KNOCKERS User Manual

Page 5

INSTALLATION INSTRUC

TIO

NS

Poison Spyder Customs • JK ROCKER KNOCKERS INSTALLATION

Page 5

©2009 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

Use a file to remove burrs, then apply some

aerosol clear coat paint to the cut edge to

prevent rust.

FIGURE 14

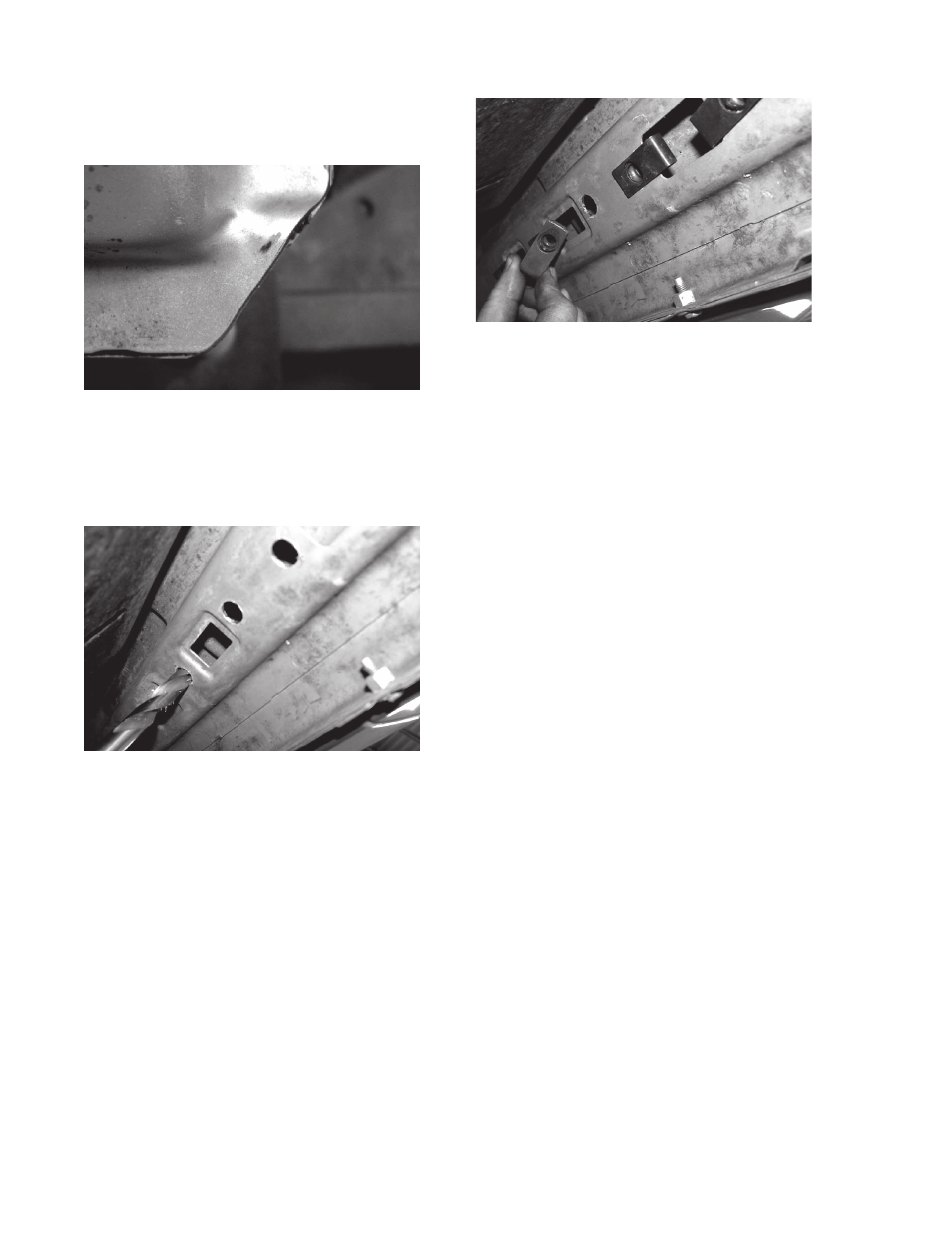

10. Remove the Rocker Knocker and set it

aside. Center-punch and drill 1/4” holes

at each of the ovals you traced into the

underside of the Jeep in step 8. Then use

the 9/16” drill to open the same holes further.

FIGURE 15

11. Use some aerosol clear coat or paint color

of your choice to coat the cut edges of the

drilled holes to prevent rust. Do this for the

holes made in step 10 as well as those made

earlier in the pinch weld flange in step 3.

12. Locate the 3/8-16 U-nut clips that are

supplied in the hardware kit. Note that some

are flat along their edges while others are

bulged. The flat-edged ones are referred

to as “skinny” nut clips, while the bulge-

edged ones are referred to as “fat” nut clips.

For each side you will use three (3) skinny

clips and five (5) fat clips. These nut clips

will slip into the rectangular holes along the

underside of the Jeep as shown in Figure 16,

allowing the nut portion of the clip to locate

at the round holes you just drilled adjacent to

the rectangular holes.

FIGURE 16

Note that some of the rectangular holes are

narrower than others, specifically at the 4th,

5th and 6th bolt locations (counting back from

the front of the Jeep). These are where you

will use the “skinny” clips, while you will use

the “fat” clips in the wider rectangular holes.

13. If installing Rocker Knockers with the

optional Slider bar, re-install the dimpled

panel that was removed in an earlier step.

Used the 1/4-20X3/4 SS flat head cap screws,

1/4 flat washers and 1/4-20 nylon insert lock

nuts that were included with the hardware kit.

There will be 22 of each of these for 2-door

JK’s, 28 of each for 4-doors. Use the 1/4”

drive ratchet, extension and 7/16” socket,

along with the 5/32” hex key, to tighten these

fasteners. CAUTION: hold the screw head

stationary with the hex key as you tighten the

nut with the ratchet. If you let the bolt head

spin it may damage the paint or powder coat.

Tighten these fasteners to 15 ft./lbs.

14. Reinstall the Rocker Knocker onto the

Jeep, this time for final installation. Carefully

align the studs with the mounting holes in the

pinch weld flange, as before. Install a 5/16”

flat washer and 5/16-18 nylon insert lock nut

onto each of the Rocker Knocker’s mounting

studs, where they protrude through the pinch

weld flange. Only finger-tighten the nuts at

this time.

15. Insert a 3/8” SS button socket head cap

screw with 3/8” split lock washer and 3/8”

flat washer (in that order, under the head

of the screw) through each of the eight (8)

elongated holes in the Rocker Knocker

mounting flange along the underside of the

Jeep, and thread into the 3/8-16 U-nut clips

previously installed at each location. Be